Паяльная паста Sn55 Pb45 SMT Оловянная паяльная HuaKe 500 г светодиодная печатная плата SMD для использования со свинцом из

- Категория: Welding Fluxes >>>

- Поставщик: Shenzhen,Huake,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 2107.60 $* | 2149.41 $* |

| Jul-16-2025 | 1709.8 $* | 1743.67 $* |

| Jun-16-2025 | 2074.61 $* | 2115.36 $* |

| May-16-2025 | 2057.96 $* | 2098.70 $* |

| Apr-16-2025 | 1642.10 $* | 1675.3 $* |

| Mar-16-2025 | 2024.72 $* | 2064.58 $* |

| Feb-16-2025 | 2007.10 $* | 2047.24 $* |

| Jan-16-2025 | 1991.50 $* | 2031.45 $* |

Характеристики

Product Description

Product Name | SMT/PCB SOLDER PASTE |

Model | Sn55 Pb45 |

Material | Tin Lead Solder Powder and Flux Paste |

Powder Size | Type 2.5,Type 3,Type 4,Type 5,Type 6 |

Quality | IPC Standards |

Wettability | Strong moisturizing ability,Good solder wettability to various devices and pads |

Printability | >8hours continous printing,no Slump,no tin beads,no bridging defects |

Application | Suitable for high-precision SMT process technology such as automotive electronics,mobile phones and computers etc. |

Melting Point | 183 degree celsius |

Package | 500g/jar and 200g/syringe |

What is SMT printing?

Surface Mount Technology (SMT) screen printers are used to print solder paste on to a surface mount assembly forming the PrintedCircuit Board (PCB) with the use of a metal mesh or stencils. It is a vital and initial part of the SMT process of every electronic device.

What is SMT Solder Paste?

Solder paste is used in the manufacture of printed circuit boards to connect surface mount components to pads on the board. It is also possible to solder through-hole pin in paste components by printing solder paste in and over the holes.

The sticky paste temporarily holds components in place; the board is then heated, melting the paste and forming a mechanical bond as well as an electrical connection.

where to use:The paste is applied to the board by jet printing, stencil printing or syringe; then the components are put in place by a pick-and-place machine or by hand.

Applications

LED Components Assembly, Moible, Earphone, Chips, Semiconductor Package, PCB, Computer Motherboard, Precision Medical Instruments, Pads, Home Appliance Boards, PPC, Photovoltaic terminal box, Thermistor, Tuner, Heat Dissipation Module, Thermal Sensor, Remote Controller, Radiator, Communication Equipment Boards and other electronics products.

Composition

A solder paste is essentially powdered solder suspended in flux paste.

HuaKe Industrial Co.,Ltd produces low-oxide spherical powder composed of SnAgCu,SnPb,SnPbAg,SnPbBi,

and SnBi,SnBiAg series in the industry standards.

HuaKe Industrial Co.,Ltd produces low-oxide spherical powder composed of SnAgCu,SnPb,SnPbAg,SnPbBi,

and SnBi,SnBiAg series in the industry standards.

Classification:by size

The size and shape of the metal particles in the solder paste determines how well the paste will "print". A solder ball is spherical in shape; this helps in reducing surface oxidation and ensures good joint formation with the adjoining particles.

Irregular particle sizes are not used, as they tend to clog the stencil, causing printing defects. To produce a quality solder joint, it's very important for the spheres of metal to be very regular in size and have a low level of oxidation.

Irregular particle sizes are not used, as they tend to clog the stencil, causing printing defects. To produce a quality solder joint, it's very important for the spheres of metal to be very regular in size and have a low level of oxidation.

Solder pastes are classified based on the particle size by IPC standard J-STD 005.The table below shows the classification type of a paste compared with the mesh size and particle size.

Mesh size in lines per inch | 80%min.between) | ||

T2.5 | -200/+325 | 25-63 | <80 |

T3 | -325/+500 | 25-45 | <90 |

T4 | -400/+635 | 20-38 | <120 |

T5 | -500/+635 | 15-25 | <150 |

T6 | -635 | 5-15 | <200 |

Solder pastes are classified into three types based on the flux types:

1.Rosin based fluxes are made with rosin, a natural extract from pine trees. These fluxes can be cleaned if required after the soldering process using a solvent (potentially including chlorofluorocarbons) or saponifying flux remover.

2.Water-soluble fluxes are made up of organic materials and glycol bases. There is a wide variety of cleaning agents for these fluxes.

3.A no-clean flux is designed to leave only small amounts of inert flux residues. No-clean pastes save not only cleaning costs, but also capital expenditures and floor space. However, these pastes need a very clean assembly environment and may need an inert reflow environment.

2.Water-soluble fluxes are made up of organic materials and glycol bases. There is a wide variety of cleaning agents for these fluxes.

3.A no-clean flux is designed to leave only small amounts of inert flux residues. No-clean pastes save not only cleaning costs, but also capital expenditures and floor space. However, these pastes need a very clean assembly environment and may need an inert reflow environment.

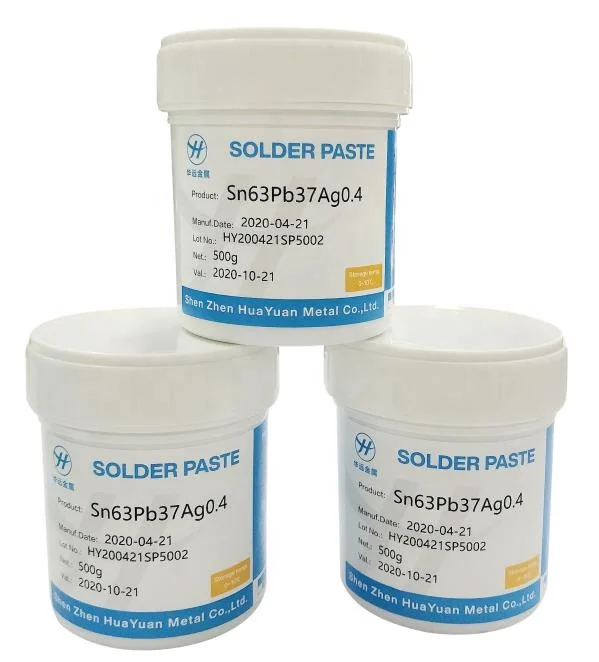

Package: We provide Jar and Syringe packing for the solder paste.

500g/jar

200g/syringe

0.5kg/jar

Process

SMT solder paste printing is the meticulous process of applying the right amount of solder paste on the solder pads. The most basic way of performing this task is to screen-print the solder paste onto the board through a stencil. Some manufacturers also prefer jet printing with this step. Solder Paste printing is the most sensitive part of the manufacturing process. Many PCB board defects often occur at this stage due to the use of substandard techniques and equipment.

The process comprises of spreading the solder paste onto the circuit board with the help of a manual or semi-automatic stencil printer. Here, a squeegee blade allows pressure for the spreading of the solder paste across the stencil which, in turn, allows even spread of solder paste on the PCB board. The blades are usually constructed from metal. One can also use polyurethane for this purpose.

Filling and Release

Stencil separation speed at which the PCB card separated from the stencil board after printing. Ideally, the servo speed should be 3mm per second; and, it must be controlled by the size of the apertures within the stencils. In any case, if the stencil separation speed deviates from the ideal value; it may not allow the solder paste to fully release from the stencil apertures and the formation of high edges around the deposits also known as “dog ears” may occur.

Properties

In using solder paste for circuit assemblies, one needs to test and understand the various rheological properties of a solder paste.

Viscosity

Viscosity

The degree to which the material resists the tendency to flow. In-house testing is sometimes needed to judge the remaining usability of solder paste after a period of use.

Thixotropic index

Solder paste is thixotropic, meaning that its viscosity changes with applied shear force (such as stirring or spreading). The thixotropic index is a measure of the viscosity of the solder paste at rest, compared to the viscosity of "worked" paste. Depending upon the formulation of the paste, it may be very important to stir the paste before use, to ensure that the viscosity is appropriate for proper application. When solder paste is moved by the squeegee on the stencil, the physical stress applied to the paste causes the viscosity to drop, allowing the paste to flow easily through the apertures on the stencil. When the stress on the paste is removed, it regains its viscosity, preventing it from flowing on the circuit board.

Slump

The characteristic of a material's tendency to spread after application. Theoretically, the paste's sidewalls are perfectly straight after the paste is deposited on the circuit board, and it will remain like that until the part placement. If the paste has a high slump value, it might deviate from the expected behavior, as now the paste's sidewalls are not perfectly straight. A paste's slump should be minimized, as slump creates the risk of forming solder bridges between two adjacent lands, creating a short circuit.

Working life

The amount of time solder paste can stay on a stencil without affecting its printing properties.

Tack

Tack is the property of a solder paste to hold a component after the component had been placed by the placement machine. Hence, tack life is the critical property of solder pastes. It is defined as the length of time

that solder paste can remain exposed to the atmosphere without a significant change in tack properties. A solder paste with long tack life is more likely to provide the user with a consistent and robust printing process.Response-to-pause

that solder paste can remain exposed to the atmosphere without a significant change in tack properties. A solder paste with long tack life is more likely to provide the user with a consistent and robust printing process.Response-to-pause

Response-to-pause

(RTP) is measured by the difference in volume of solder paste deposition as a function of number of prints and pause time. A large variation in the print volume after a pause is unacceptable as this causes end of line defects such as shorts or opens. A good solder paste shows less variation in the volume of the prints after pause. However, another may show large variations and also an overall decreasing trend in volume.

(RTP) is measured by the difference in volume of solder paste deposition as a function of number of prints and pause time. A large variation in the print volume after a pause is unacceptable as this causes end of line defects such as shorts or opens. A good solder paste shows less variation in the volume of the prints after pause. However, another may show large variations and also an overall decreasing trend in volume.

Storage

Solder paste must be refrigerated when transported and stored in an airtight container at a temperature between 0-10 °C. It should be warmed to room temperature before use.Refrigerate to guarantee stability @1-10℃,when stored under this conditions,the shelf lif is 6 months from the manufacturing date.

FAQ

How do I choose solder paste?

When choosing a solder alloy, there are four key considerations: lead content, melting temperature, alloy powder particle size, and joint strength. Lead content, melting temperature, and strength are typically addressed at the same time.

What is Type 3 solder paste?

The main particle size range is normally associated with the type. For example, Type 3 solder powder mainly falls within the 25 – 45 µm size range, therefore Type 3 solder paste may be labeled as “Type 3 (25-45 µm).”

Why use low temperature solder paste?

Low-temperature solder pastes are used in electronics production where the use of solder pastes based on SAC alloys is impossible due to the temperature sensitiveness of the components or printed circuit boards. The most commonly used low-temperature solder paste is tin and bismuth-based.

Company Introduction

Shenzhen Huake Industrial Co., Ltd. was founded in 2002. It is a leading enterprise with complete tin industry chain in China and a large-scale specialized comprehensive enterprise integrating research and development, production, sales and service of electronic welding materials and electronic new materials.

Huake Industry has established branches in Suzhou, Chongqing, Hangzhou, Qingdao, Xiamen and other major cities, forming a huge sales and service network, and is committed to becoming an overall solution provider and one-stop electronic new material service provider for electronic welding materials. We are in line with the team spirit of "honesty, truth-seeking, efficiency and innovation", the corporate culture concept of benevolence and harmony, first-class product quality and service, and win the support and trust of customers. We are willing to work together with friends from all over the world and colleagues from all walks of life to seek common development.

Huake Industry's products are widely used in PCB plating,THT,HASL, SMT,etc., enjoying a good reputation in related fields, with a number of well-known large IT and electronic manufacturing Corporate customers,covering a wide range of electronics, communications, automotive, LED, and electrical appliance manufacturing.

Huake Industry has established branches in Suzhou, Chongqing, Hangzhou, Qingdao, Xiamen and other major cities, forming a huge sales and service network, and is committed to becoming an overall solution provider and one-stop electronic new material service provider for electronic welding materials. We are in line with the team spirit of "honesty, truth-seeking, efficiency and innovation", the corporate culture concept of benevolence and harmony, first-class product quality and service, and win the support and trust of customers. We are willing to work together with friends from all over the world and colleagues from all walks of life to seek common development.