Высококачественный натуральный пластик LDPE Clear заводская цена

- Категория: LDPE >>>

- Поставщик: Julier,(xiamen),Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.94 $* | 0.72 $* |

| Aug-17-2025 | 0.41 $* | 0.59 $* |

| Jul-17-2025 | 0.27 $* | 0.14 $* |

| Jun-17-2025 | 0.2 $* | 0.83 $* |

| May-17-2025 | 0.59 $* | 0.74 $* |

| Apr-17-2025 | 0.73 $* | 0.29 $* |

| Mar-17-2025 | 0.78 $* | 0.58 $* |

| Feb-17-2025 | 0.79 $* | 0.89 $* |

| Jan-17-2025 | 0.42 $* | 0.46 $* |

Характеристики

Products Description

Product Name | LDPE Low Density Polyethylene | ||||||

Advantages | Free sample On-time deliveryEnvironment friendly Can be reinforced with the glass fiber/toughness/flame retardant/UV stabilized Competitive price High quality | ||||||

About Inquiry | In order to give you a satisfactory quotation as soon as possible and to find materials that are perfectly suited to your products please tell us the details: 1.Virgin or recycled 2. Any additives, such as uv-stablized, light diffusion, flame retardant, etc. 3. Injection or extrusion 4. To make what product 5. Color | ||||||

Low-density polyethylene, also known as high-pressure polyethylene (LDPE), is the lightest variety of polyethylene resins. It has good flexibility, extensibility, electrical insulation, transparency, easy processing and certain air permeability. It has good chemical stability, alkali resistance and general organic solvent resistance.

The main characteristics of low density polyethylene are as follows:

(1) The film is slightly opalescent and transparent, soft. The strength is smaller than that of high-density polyethylene, and the impact strength is greater than that of high-density polyethylene.

(2) Cold resistance, low temperature resistance and high temperature resistance. Thicker films can withstand the sterilization process of immersion in hot water at 90°C.

(3) It has good moisture-proof performance, stable chemical performance, and is insoluble in common solvents.

(4) It has great air permeability, so when it is used as food packaging that is easy to oxidize, the storage period of its contents should not be too long.

(5) The oil resistance is poor, and the product can be slowly swelled. When packaging greasy food, the food will have a flaky smell after long-term storage.

(6) Long-term exposure to ultraviolet rays and heat will cause aging, affecting its physical properties and dielectric properties.

(7) The melting point is 110~115°C, and the processing temperature is 150~210°C. If it is in an inert gas, the temperature can reach 300°C and it is still stable. However, the melt is prone to degradation in contact with oxygen.

Application areas:

Scope of application of low density polyethylene: suitable for food packaging such as seasonings, cakes, sugar, candied fruit, biscuits, milk powder, tea, fish floss and so on. Tablets, powders and other pharmaceutical packaging, shirts, clothing, knitted cotton products and chemical fiber products and other fiber products packaging. Packaging of daily chemical products such as washing powder, detergent, cosmetics, etc. Due to the poor mechanical properties of the single-layer PE film, it is usually used as the inner layer of the composite packaging bag, that is, the heat-sealing substrate of the multi-layer composite film.

The main characteristics of low density polyethylene are as follows:

(1) The film is slightly opalescent and transparent, soft. The strength is smaller than that of high-density polyethylene, and the impact strength is greater than that of high-density polyethylene.

(2) Cold resistance, low temperature resistance and high temperature resistance. Thicker films can withstand the sterilization process of immersion in hot water at 90°C.

(3) It has good moisture-proof performance, stable chemical performance, and is insoluble in common solvents.

(4) It has great air permeability, so when it is used as food packaging that is easy to oxidize, the storage period of its contents should not be too long.

(5) The oil resistance is poor, and the product can be slowly swelled. When packaging greasy food, the food will have a flaky smell after long-term storage.

(6) Long-term exposure to ultraviolet rays and heat will cause aging, affecting its physical properties and dielectric properties.

(7) The melting point is 110~115°C, and the processing temperature is 150~210°C. If it is in an inert gas, the temperature can reach 300°C and it is still stable. However, the melt is prone to degradation in contact with oxygen.

Application areas:

Scope of application of low density polyethylene: suitable for food packaging such as seasonings, cakes, sugar, candied fruit, biscuits, milk powder, tea, fish floss and so on. Tablets, powders and other pharmaceutical packaging, shirts, clothing, knitted cotton products and chemical fiber products and other fiber products packaging. Packaging of daily chemical products such as washing powder, detergent, cosmetics, etc. Due to the poor mechanical properties of the single-layer PE film, it is usually used as the inner layer of the composite packaging bag, that is, the heat-sealing substrate of the multi-layer composite film.

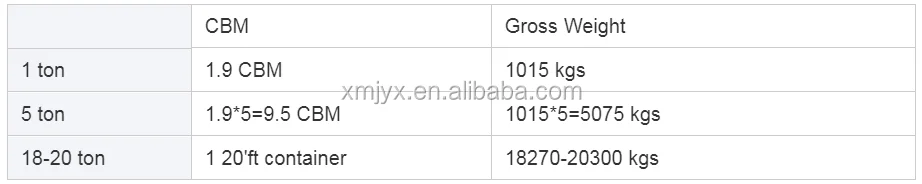

Product packaging

Certifications

FAQ

1. About Factory

It is closed to Xiamen port.

2. About Sample

FREE SAMPLE

3. About Material

We can customize the material performance according to customers’ requirement.

4. About Color

We can match the material color according to color card PANTONES or RAL.

If you don't know color card number, you can send us product.

5. About Process Method

Full technical/process support.

6. About Delivery Period

About 7 working days for 10tons, 10 working days for 18-20 tons.

3. About Material

We can customize the material performance according to customers’ requirement.

4. About Color

We can match the material color according to color card PANTONES or RAL.

If you don't know color card number, you can send us product.

5. About Process Method

Full technical/process support.

6. About Delivery Period

About 7 working days for 10tons, 10 working days for 18-20 tons.

7. About Payment Term

It’s flexible, TT, L/C at sight, PAYPAL, BANK, Alibaba’s Trade Assurance, etc.

Customer Photos

Recommend Products

Похожие товары

Гранулы ПНД, пластиковое сырье, гранулы ПНД-пленки

US $650.00-$1100

Прозрачная пленка LDPE/перерабатываемый Пластиковый лом LDPE/пленка LDPE

US $65.00-$100.00

Ldpe Смола ldpe цены на сырье для общего пластикового сырья HDPE/LDPE/LLDPE

US $513.00-$764.00