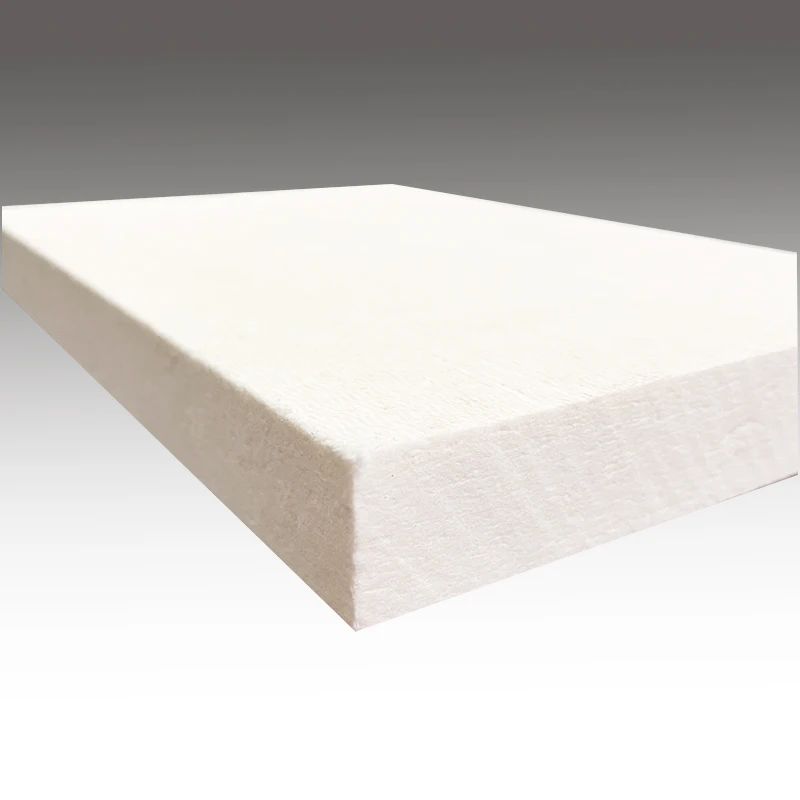

Огнеупорная плита 1800c огнеупорный материал изоляционная облицовочная из керамического

- Категория: Ceramic Fiber Boards >>>

- Поставщик: Shandong,Robert,New,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 4.48 $* | 4.1 $* |

| Jul-18-2025 | 3.16 $* | 3.99 $* |

| Jun-18-2025 | 4.77 $* | 4.39 $* |

| May-18-2025 | 4.78 $* | 4.24 $* |

| Apr-18-2025 | 3.29 $* | 3.52 $* |

| Mar-18-2025 | 4.41 $* | 4.53 $* |

| Feb-18-2025 | 4.88 $* | 4.41 $* |

| Jan-18-2025 | 4.55 $* | 4.62 $* |

Характеристики

Products Description

Ceramic fiber board

Ceramic fiber board is made of ceramic fiber cotton with a small amount of organic or inorganic binder. It has a smooth surface, accurate size, good toughness, can be cut arbitrarily, and has excellent thermal stability. It can be widely used in metallurgy, ceramics, glass, petrochemical , non-ferrous metals and other industrial kilns, it is an ideal thermal insulation and thermal insulation material.

Product Specification

Item | COM | STD | HC | HA | HZ | HAZ | |||||

Classification Temperature (℃) | 1050 | 1260 | 1260 | 1360 | 1430 | 1400 | |||||

Working Temperature (℃)≤ | 1000 | 1050 | 1100 | 1200 | 1350 | 1200 | |||||

Slag Content (%)≤ | 18 | 13 | 13 | 13 | 10 | 10 | |||||

Bulk Density (kg/m3) | 280~320 | ||||||||||

Thermal Conductivity (W/m.k) | 0.086 (400℃) 0.120 (800℃) | 0.086 (400℃) 0.120 (800℃) | 0.086 (400℃) 0.110 (800℃) | 0.092 (400℃) 0.186 (1000℃) | 0.092 (400℃) 0.186 (1000℃) | 0.98 (400℃) 0.20 (1000℃) | |||||

Permanent Linear Change (%)24h | -4/1000℃ | -3/1000℃ | -3/1100℃ | -3/1200℃ | -3/1350℃ | -3/1400℃ | |||||

Modulus of Rupture (MPa) | 0.2 | ||||||||||

Al2O3(%) ≥ | 44 | 45 | 45 | 50 | 39 | 39 | |||||

Fe2O3(%) ≤ | 1.0 | 1.0 | 0.2 | 0.2 | 0.2 | 0.2 | |||||

Al2O3+SiO2 (%)≤ | 98 | 99 | 99 | 99 | 84 | 90 | |||||

ZrO2(%) ≥ | 11~13 | 5~7 | |||||||||

Regular Size(mm) | 900/1000/1100*500/600/700*25/50/100 | ||||||||||

Features

1. Can be machined, cut and shaped easily;

2. High rigidity and light weight;

3. Structure homogeneity and easy machining;

4. Even fiber with stable property;

5. High compression strength;

6. Accurate dimension and good paleness;

7. Excellent thermal shock resistance;

8. High rigidity and light weight;

9. Low thermal conductivity, low heat storage;

Applications

1. Cement building industry, kiln back lining-thermal insulation;

2. Ceramic industry-lining of various kilns for thermal insulation;

3. Petrochemical and metallurgy industries- back linings, wall linings, and ling thermal insulation;

4. Glass kiln lining and back lining thermal insulation;

5. Heat treatment furnace kiln back lining thermal insulation;

6. Aluminum factories-reduction cell firebricks back linings;

7. High temperature reaction, heating device-wall lining and back linings

2. Ceramic industry-lining of various kilns for thermal insulation;

3. Petrochemical and metallurgy industries- back linings, wall linings, and ling thermal insulation;

4. Glass kiln lining and back lining thermal insulation;

5. Heat treatment furnace kiln back lining thermal insulation;

6. Aluminum factories-reduction cell firebricks back linings;

7. High temperature reaction, heating device-wall lining and back linings

Product Application

Company Profile

Exhibition

Why Choose Us

Mr. Vincent

We have cooperated with RBT company for more than 5 years, every order is delivered on time, and the product quality is good.

I am very happy to have long-term cooperation with reliable suppliers, and hope to maintain such cooperation forever.

Mr. Shawn

RBT is one of my favorite suppliers, they know the product very well and often help me with some design problems. And their service is very good, I like this cooperation model very much.

Mrs. Mia

I am a trader, and the quality and stability of RBT's products is very good, which has helped me maintain many end customers and provided me with great help in developing the market.

FAQ

Q1: Are you a manufacturer or a trader?

A1: We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

Q2 : How do you control your quality?

A2 : For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Q3: What is your delivery time?

A3 : Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Q4 : Do you provide free samples?

A4 : Of course, we provide free samples.

Q5 : Can we visit your company?

A5 : Yes, of course, you are welcome to visit RBT company and our products.

Q6: What is the MOQ for trial order?

A6 : There is no limit, we can provide the best suggestion and solution according to your situation.

Q7: Why choose us?

A7: We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

A1: We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

Q2 : How do you control your quality?

A2 : For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Q3: What is your delivery time?

A3 : Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Q4 : Do you provide free samples?

A4 : Of course, we provide free samples.

Q5 : Can we visit your company?

A5 : Yes, of course, you are welcome to visit RBT company and our products.

Q6: What is the MOQ for trial order?

A6 : There is no limit, we can provide the best suggestion and solution according to your situation.

Q7: Why choose us?

A7: We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.

Recommend Products