Высокоплотная автоматическая промышленная стальная радиоуправляемая система стеллажа поддонов

- Категория: Cargo & Storage Equipment >>>

- Поставщик: Anhui,Huayide,Intelligent,Storage,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.91 $* | 0.18 $* |

| Aug-19-2025 | 0.53 $* | 0.17 $* |

| Jul-19-2025 | 0.7 $* | 0.6 $* |

| Jun-19-2025 | 0.90 $* | 0.60 $* |

| May-19-2025 | 0.43 $* | 0.71 $* |

| Apr-19-2025 | 0.35 $* | 0.93 $* |

| Mar-19-2025 | 0.18 $* | 0.36 $* |

| Feb-19-2025 | 0.46 $* | 0.78 $* |

| Jan-19-2025 | 0.40 $* | 0.81 $* |

Характеристики

Product Description

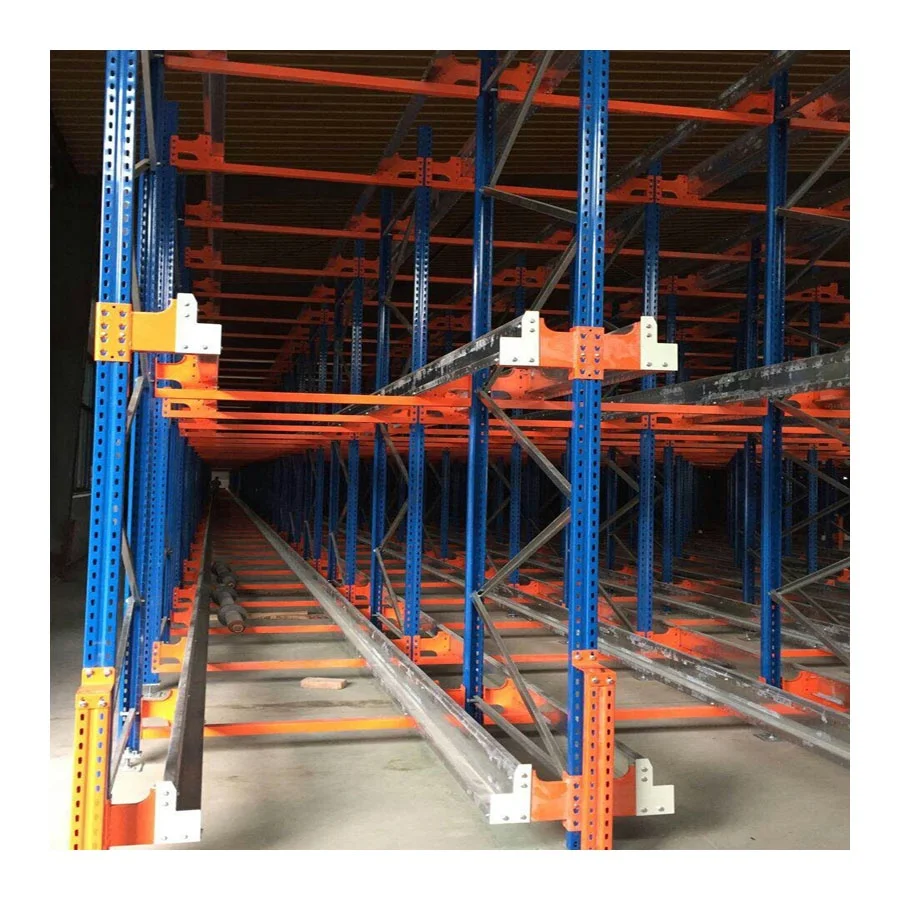

Radio Shuttle Racking Warehouse Storage System FIFO And FILO Pallet In Good Price High Density

Radio shuttle racking is a semi-automated high-density storage system.This system consists of forklift, racking system and shuttle.Forklift carries goods onto shuttle. Shuttle automatically take the goods into racking system and come true the storage function.Radio shuttle racking can work continuously so the whole work efficiency is enhanced.Radio shuttle racking could helps you to create maximum use of the storage and simplifies loading and unloading of goods.

We are committed to providing customers with the most perfect high-density storage solutions:

--high-tech

--high-density

--high-speed

--high-performance

--high-density

--high-speed

--high-performance

Independent research and development manufacturer!!!

Shuttle cart and racking system have independent intellectual property rights:

Shuttle cart patent no. : 201320201125.1

Lift patent no. :201220168373.6;Patent announcement no.: 201210116458.4

Shuttle cart guide rail support bar patent no.:201320204126.1

Shuttle cart guide rail and guide rail parts patent no.:201320198325.6

Shuttle racking pallet guide plate patent no.:201320202208.2

Shuttle cart and racking system have independent intellectual property rights:

Shuttle cart patent no. : 201320201125.1

Lift patent no. :201220168373.6;Patent announcement no.: 201210116458.4

Shuttle cart guide rail support bar patent no.:201320204126.1

Shuttle cart guide rail and guide rail parts patent no.:201320198325.6

Shuttle racking pallet guide plate patent no.:201320202208.2

Features

1.High-density storage, the storage capacity of the same space is 2 times higher than that of ordinary fixed shelves.

2.Safe, the shelf structure is stable, and the forklift does not need to enter and exit the interior of the shelf to prevent collision with the shelf.

3.Efficient, when the forklift transports the goods, the trolley operates independently, and the forklift trolley crosses the operation for efficient access.

4.Convenient, in the first-in first-out mode, the in-out library can be easily switched.

2.Safe, the shelf structure is stable, and the forklift does not need to enter and exit the interior of the shelf to prevent collision with the shelf.

3.Efficient, when the forklift transports the goods, the trolley operates independently, and the forklift trolley crosses the operation for efficient access.

4.Convenient, in the first-in first-out mode, the in-out library can be easily switched.

Radio Shuttle

parameter :

1. The motor is brushed and brushless, and the remote control is one-way and Chinese display are optional;Horizontal motor power: 400W, German Lenz geared motor;Vertical motor power: 370W, Taiwan Aideli;

2. The lifting height of the jacking system is 40mm, about 20mm higher than the track

3. If the battery is not used for a long time, charge it every 6 months. Cycle charging more than 1000 times.

2. The lifting height of the jacking system is 40mm, about 20mm higher than the track

3. If the battery is not used for a long time, charge it every 6 months. Cycle charging more than 1000 times.

Specification

item | value |

Place of Origin | Anhui,China |

Brand Name | Hua Yide |

Model Number | HYD-SR |

Scale | Heavy Duty |

Capacity | Customized |

Structure | Assembled Freely |

Surface treatment | Powder Coated |

Main Parts | Upright frame, beam and related accessories |

Application | Widely |

Weight Capacity | 500~5000kg |

Packing & Delivery

Plastic banding+Stretch film wrapped,easy loading and unloading with standard forklift truck or pallet jack

Certifications

Company Profile

Anhui Hua Yide Intelligent Storage Equipment Co., Ltd. devotes itself to the design and manufacture of storage equipment. We are specialized in producing various pallet rack, cantilever rack, electric mobile rack storage system, mezzanine rack, shuttle cart automatic storage system, drive in rack, carton flow rack, stacking rack ,AS/RS and other related storage equipment system. We have formed a variety of logistics solutions covering pharmaceutical and chemical, beverage and food, home appliances, the third Party Logistics and other industries. Our products comply to EN, ANSI, JIS, and FEM standard. We are committed to providing our customers with the best warehouse planning services.

Main Facilities and Equipments:

2 steel shelf production lines

16 automated punching & rolling lines-upright

8 automated rolling lines-beam

6 pre-treatment & automated powder coating lines

3 automated welding robot stations

2 steel pallet production lines

60 co2 welding machines

50 cutting, bending and punching machines

Work apparatus production lines

We have passed ISO9001:2015 quality management system certification and ISO14001:2015 environmental management system certification and BSOHSAS18001:2007 occupational health safety management system certification,and have many honor of Software copyright & patent for AS/RS, AGV system.

Main Facilities and Equipments:

2 steel shelf production lines

16 automated punching & rolling lines-upright

8 automated rolling lines-beam

6 pre-treatment & automated powder coating lines

3 automated welding robot stations

2 steel pallet production lines

60 co2 welding machines

50 cutting, bending and punching machines

Work apparatus production lines

We have passed ISO9001:2015 quality management system certification and ISO14001:2015 environmental management system certification and BSOHSAS18001:2007 occupational health safety management system certification,and have many honor of Software copyright & patent for AS/RS, AGV system.

FAQ

1.Are you manufacture or trading company?

We are manufacture. We devote to the design and manufacture of storage equipment.

2.What's your advantage?

*Factory direct sale competitive price.

*Experienced professional engineers.

3.What's the international trading process?

Design drawing → Confirm drawing → Quotation → PI → Confirm PI → Arrange 30% deposit → Manufacture → QC inspect → Pay balance

→Shipping.

4.What is your sample policy?

We can supply the sample, but the customers have to pay the sample cost and the courier cost.

5.What is the term of payment?

30% T/T down payment and 70% T/T before delivery.

6.Do you test all your goods before delivery?

Yes. We have 100% test before delivery.

7.What is your delivery time?

Generally, 15 to 25 days after receiving your advance payment. It also depends on the order quantity and customized time.

8. May I know the status of my order?

Yes. We will send you information and photos at different production stage of your order. You will get the latest information in

time.

9.How could I install the racks?

We provide detailed install instruction for our customers. We can also let our engineers to teach you for free.

We are manufacture. We devote to the design and manufacture of storage equipment.

2.What's your advantage?

*Factory direct sale competitive price.

*Experienced professional engineers.

3.What's the international trading process?

Design drawing → Confirm drawing → Quotation → PI → Confirm PI → Arrange 30% deposit → Manufacture → QC inspect → Pay balance

→Shipping.

4.What is your sample policy?

We can supply the sample, but the customers have to pay the sample cost and the courier cost.

5.What is the term of payment?

30% T/T down payment and 70% T/T before delivery.

6.Do you test all your goods before delivery?

Yes. We have 100% test before delivery.

7.What is your delivery time?

Generally, 15 to 25 days after receiving your advance payment. It also depends on the order quantity and customized time.

8. May I know the status of my order?

Yes. We will send you information and photos at different production stage of your order. You will get the latest information in

time.

9.How could I install the racks?

We provide detailed install instruction for our customers. We can also let our engineers to teach you for free.