От A до Z малая Линия по Производству Бутилированной минеральной питьевой воды машина для розлива под

- Категория: Packaging Machines >>>

- Поставщик: Jiangmen,Tings,Drinking,Water,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 13090.68 $* | 13745.57 $* |

| Aug-19-2025 | 12980.21 $* | 13629.66 $* |

| Jul-19-2025 | 10890.63 $* | 11435.56 $* |

| Jun-19-2025 | 12760.84 $* | 13398.75 $* |

| May-19-2025 | 11110.36 $* | 11666.72 $* |

| Apr-19-2025 | 12540.15 $* | 13167.58 $* |

| Mar-19-2025 | 12430.72 $* | 13052.71 $* |

| Feb-19-2025 | 12320.96 $* | 12936.80 $* |

| Jan-19-2025 | 12210.5 $* | 12821.55 $* |

Характеристики

Machine Details

Send us an inquiry to get the customized proposal and get 5% off discount!!!

A to Z small bottled mineral drinking water production line turnkey water bottling plant

Do you have the ideas about your project,like below:

1. Your requested capacity (how many bottle per hour),we offer 2000-25,000BPH for choice?

2. The bottle size in Liter or ml. 500ml,or 750ml,or...?

3.And how many sizes?

We can customized all kinds of capacity from 2000bph -25,000bph(bottle per hour)

3.And how many sizes?

We can customized all kinds of capacity from 2000bph -25,000bph(bottle per hour)

Flow Chart

——Bottled Water Filling Line

Turnkey solution from a to z

We supply from water purification system,to filling,labeling,and package machine,as well as blowing machine,and supply all of the raw material like pet prefroms,label,and PE film.

Full Automatic Blow Molding Machine

The machine is suitable for blowing all shapes of PET water bottles, carbonated beverage bottles, juice bottles, wine bottles, oil bottles, seasoning bottles, cleaning liquid bottles, container cans, etc.Capacity: Depends on the filling machine speed(We will recommend you)

Cavity: 2, 4,6or 8

Bottle volume: 200ml to 2000ml

Maximum bottle diameter: 100mm

Maximum bottle height: 350mm

Semi-automatic blow molding machines for small capacity are available.

Application: This machine is a washing-filling-capping integrated machine, which is mainly used for Non-carbonated drink, such as mineral water, pure water and so on. It is designed for shortening the contact time between drink material and outside, so as to improve the sanitation condition of the water product and increase the economy benefit.

Features: It is designed with hanging type bottle conveying structure which makes the conveying of the bottles more convenient, faster and easier. Its main machine is equipped with advanced PLC control and key electric elements with international famous brand.

Machine Type | Automatic rotary 3 in 1 rinser-filling-capping monoblock machine |

Bottle Type | PET round or square bottle Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm |

Capacity | 2000BPH,3000BPH,4000BPH,5000BPH,6000BPH,Or large volume can be customized as well. |

Certificates | CE / SGS / ISO 9001 |

Air Conveyor(Inlet bottle)

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- Made of stainless steel 304/316.

- High quality carbon steel welded rack and frame

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- Made of stainless steel 304/316.

- High quality carbon steel welded rack and frame

Filled bottle conveyor(outlet bottle)

- Made of stainless steel 304/316.

- High quality carbon steel welded rack and frame

The length is 2meter.

-We will recommend the length if you have the plant layout

Bottle rinser/washing bottle

- The washing table connect to the air conveyor directly, which make the working environment much cleaner.

- All 304/316 stainless steel nozzle, water inject design, high injecting accuracy, save water.

- All 304/316 stainless steel nozzle, water inject design, high injecting accuracy, save water.

- 304/316 Stainless steel plier, high washing accuracy ensure no bottle falling during washing process.

- 304/316 stainless steel washing pump, durable and clean

- 304/316 stainless steel washing pump, durable and clean

Bottle filling

- 304/316 Stainless steel high accuracy filling nozzle

- Filling volume adjustable, all bottles with same liquid volume after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no welding spot, easy to clean

- 304/316 stainless steel filling pump

- High accuracy inject nozzle, save water

- Filling volume adjustable, all bottles with same liquid volume after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no welding spot, easy to clean

- 304/316 stainless steel filling pump

- High accuracy inject nozzle, save water

Bottling Capping

- Electromagnetic capping heads, minimize the bottle falling during capping process

- All 304/316 stainless steel construction

- High capping accuracy, no cap missing

- Automatic stop when there are insufficient bottles

- Stable and reliable capping process, Defective rate ≤0.2%

- All 304/316 stainless steel construction

- High capping accuracy, no cap missing

- Automatic stop when there are insufficient bottles

- Stable and reliable capping process, Defective rate ≤0.2%

Code Ink-jet Machine

This device print the code onto the bottle body.

We supply laser and CIJ inkjet coder for your choice.

If you want to know the difference of the,send me message,will be glad to explain,and help you make choice.

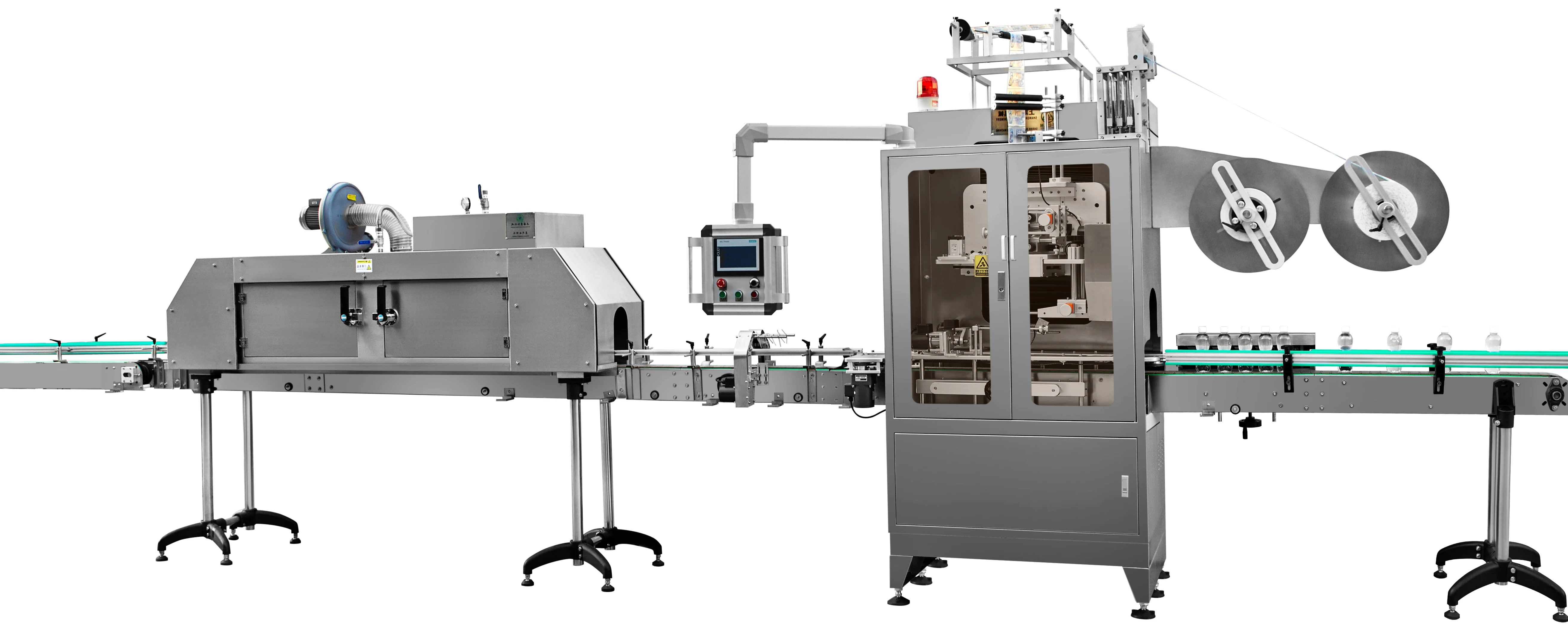

Steam Sleeve labeling system

This device is for labeling the bottle by high temperature steam shrinking plastic label.

We also supply semi-auto,or auto self adhesive labeling machine and auto opp labeling machine.

Shrink Wrapping Package Machine

This machine groups the bottled water and packs them with plastic film by high temperature shrinking.

We offer semi-auto,and full auto shrink wrapping machine.

Send us inquiry if you want to compare both machine!Video and offer will sent to help you make choice!

FAQ

HOW TO FIND TINGS?

● Search Jiangmen Tings Drinking Water Equipment Co., Ltd. on Alibaba, remember to choose manufacturer, not trader

● Visit exhibition in Canton Fair or trade fairs abroad or come to our factory directly!

● Send Tings an inquiry through Alibaba or our website

● Tings's sales manager will reply you in short time and add instant chatting tool

● Visit exhibition in Canton Fair or trade fairs abroad or come to our factory directly!

● Send Tings an inquiry through Alibaba or our website

● Tings's sales manager will reply you in short time and add instant chatting tool

CAN I VISIT YOUR FACTORY?

● Welcome to visit our factory anytime.

● Seeing is believing. Please come to out factory to know more about our R&D, sales, after sales and quality control team, as well as our production process and capacity.

● Seeing is believing. Please come to out factory to know more about our R&D, sales, after sales and quality control team, as well as our production process and capacity.

TELL ME HOW YOUR FACTORY CONTROL THE QUALITY?

● We use high accuracy processing equipment for production, and we are experienced in making our machine for over 20 years.

● Each component before assembly needs will be strictly test by our professional QC.

● Each component before assembly needs will be strictly test by our professional QC.

HOW ABOUT YOUR AFTER-SALES SERVICE?

● We will debug all machines after production. Then we will send our customer pictures or videos of the testing for all machines.

● we will pack all machines by standard export package for long-distance shipment.

● we will pack all machines by standard export package for long-distance shipment.

● According to the customer's request, we can arrange to send our engineers to customers' factory to do the installation and training.

● Our after-sales team are formed by our engineers, sales managers and after-sales service manage, who will follow our customers' project.