Машина для производства жидкого мыла и шампуня AILUSI 100L-5000L емкость смешивания гомогенизатор производственная

- Категория: Mixing Equipment >>>

- Поставщик: Yangzhou,Ailusi,Chemical,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 6545.72 $* | 6872.19 $* |

| Aug-17-2025 | 6490.57 $* | 6815.34 $* |

| Jul-17-2025 | 5445.51 $* | 5717.54 $* |

| Jun-17-2025 | 6380.20 $* | 6699.63 $* |

| May-17-2025 | 5555.10 $* | 5833.81 $* |

| Apr-17-2025 | 6270.36 $* | 6584.72 $* |

| Mar-17-2025 | 6215.40 $* | 6526.5 $* |

| Feb-17-2025 | 6160.17 $* | 6468.13 $* |

| Jan-17-2025 | 6105.32 $* | 6410.56 $* |

Характеристики

AILUSI Machinery

Manufacturer of Cosmetic | Pharmaceutical | Food | Daily Chemical industrial | GMP Standard

Product Overview

Small scale liquid bar soap making machine small soap making machine liquid washing mixer

Homogenizing mixer machine has high-speed disperser, mixing and disperse viscously, solid and liquid, etc. various kind of raw material will be dissolved which is such as AES, AESA LSA, during liquid production which can save energy consumption and shorten production the and shorten production period. To produce liquid washing products, like shampoo, liquid soap, bath shower, dishwashing, hand washing, lubricating oil, etc.

This machine is the equipment commonly used by daily chemical companies such as cosmetic shampoo, shower gel, hand sanitizer and so on. Through the adjustable speed stirring of the paddle in the pot and the homogenizer at the bottom, the materials are fully mixed and blended and stirred evenly. According to the requirements of the production process, the materials can be heated or cooled by heating in the jacket. Set a specific temperature, when the temperature reaches the required requirements, the heating device automatically stops heating.

The mixing pot can also be equipped with a platform. The control cabinet is designed and installed on the platform. The heating, mixing speed control, and heating time are all completed on a unified operating platform, which is easy to operate and efficient.

FEATURES AT A GLANCE

1. The Omnidirectional wall scraping and mixing adopts a frequency converter to adjust the speed. At low temperatures and high

viscosity, it can reduce the formation of bubbles.

2. Jacket heating and cooling function (steam/electric heating)

3. The pot body is welded by three layers of stainless steel plates, mirror polished, in line with GMP requirements.

4. High-speed shearing homogenizer 3600rpm, strong mixing of solid and liquid raw materials.

5. Schneider switch control button, Delta inverter, Omron temperature control

3. The pot body is welded by three layers of stainless steel plates, mirror polished, in line with GMP requirements.

4. High-speed shearing homogenizer 3600rpm, strong mixing of solid and liquid raw materials.

5. Schneider switch control button, Delta inverter, Omron temperature control

Right elevation

Left elevation

Front elevation

Details Images

Lid

Pipe: All contact material parts adopt GMP hygiene standards SUS316L, Sanitation grade accessories & valves

Electric control system

Can be customized to PLC+ Touch screen

Outer layer material: adopt SUS304 Stainless steel plate, thickness:1.5mm

Meter: thermometer, Time digital display met, voltmeter, Homogenizer time reply

Button: Each function switch control button, emergency switch, light switch, start/stop buttons

Indicate Light: RYG 3 colors indicate light and all system working indicate

The electrical components: include various control relay

Outer layer material: adopt SUS304 Stainless steel plate, thickness:1.5mm

Meter: thermometer, Time digital display met, voltmeter, Homogenizer time reply

Button: Each function switch control button, emergency switch, light switch, start/stop buttons

Indicate Light: RYG 3 colors indicate light and all system working indicate

The electrical components: include various control relay

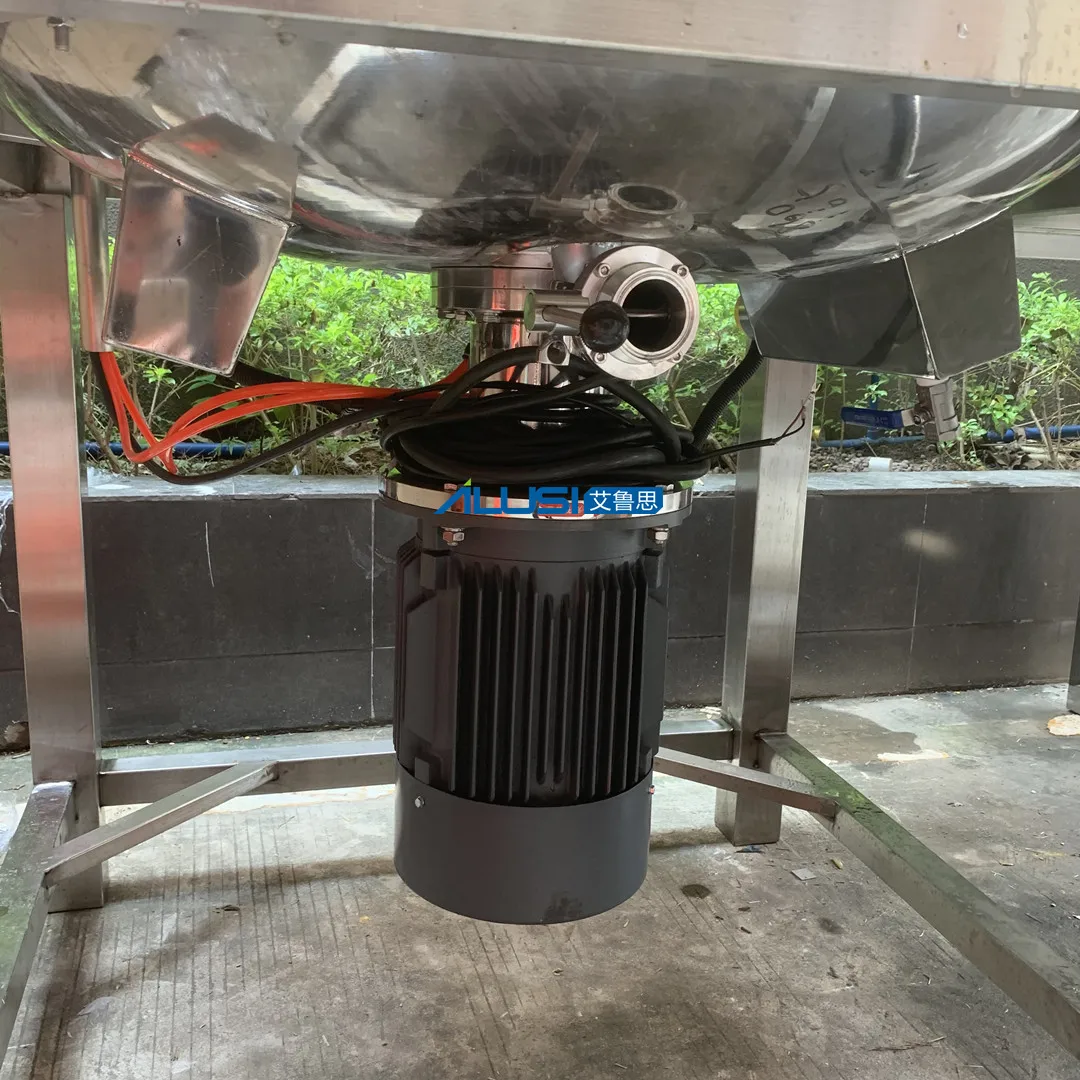

Homogenizer

Bottom Homogenizer (can be customized to upper homogenizer)

Material: SUS316L

Motor power: Depends on capacity

Speed: 0-3600rpm, DELTA inverter

Processing methods: Rotor and stator adopts wire-cutting finish machining, polishing treatment before assembly

Material: SUS316L

Motor power: Depends on capacity

Speed: 0-3600rpm, DELTA inverter

Processing methods: Rotor and stator adopts wire-cutting finish machining, polishing treatment before assembly

Stirrer paddle & scraper blade

Frame oar wall single way scrapping mixing (can be customized to double way mixing, circulation mixing etc.)

Stirrer paddle: SUS316L

Scraper blade: PTFE material, white

Motor power: Depends on capacity

Speed: 0-75rpm, DELTA inverter

Adopting Germany Bergman mechanical seal, NSK bearing made in Japan

Stirrer paddle: SUS316L

Scraper blade: PTFE material, white

Motor power: Depends on capacity

Speed: 0-75rpm, DELTA inverter

Adopting Germany Bergman mechanical seal, NSK bearing made in Japan

Heating element

Electric heating method Heat the thermal oil or water in the interlayer. Different powers are suitable for pots of different

capacities

capacities

Motor

Stirring motor

Homogeneous motor

Siemens BEIDE or ABB brand.

Homogeneous motor

Siemens BEIDE or ABB brand.

PRODUCT SPECIFICATIONS

Model | AHM-1000 |

Working capacity | 1000L |

Heating method | Steam/electric |

Mixing type | Upper frame oar scrape mixer |

Mixing motor power | 4KW |

Mixing frequency | 4KW |

Mixing Speed | 0-65rpm |

Homogenizer | Bottom homogenizer with frequency inverter |

Bottom Homogenizer power | 7.5KW |

Homogenizer frequency | 7.5KW |

Speed | 0-3600rpm (60Hz) |

Control method | Button control/ HMI |

Frequency converter | Delta/Panasonic/Mitsubishi |

Electrical components | Schneider/Delixi |

Jacket | Double jacket,3 layers |

Tank materials | Inner layer 5mm/SUS316 Middle layer 5mm/SUS304 Outer layer 3mm/SUS304 |

PRODUCT CONFIGURATION

Siemens Motor

Reducer

Delta Frequency inverter

Stator and rotor

Rotor

Materials SUS304&316L(TISCO)

Burgmann Mechanical seal

NSK Bearing

Omron temperature controller

Time Relay

Breaker

AC contactor

Indicator light, Schneider

Button , Schneider

Current Transformer,Delixi

Packing & Delivery

Packing

In strong wooden case(s), suitable for long-distance ocean/parcel post/air freight or land transportation and to change of climate, well protected against moisture and shocks.

Certifications

Project

Company Profile

Yangzhou Ailusi Chemical Machinery factory is located in Gaoyou City, Jiangsu Province, China. We have more than 16 years of experience and 9800 square meters factory. Mainly apply to Cosmetic, Chemical, Food, Pharmaceutical industry etc., we could provide superior quality and customer trusted products to clients are based on advanced production equipment, perfect technical process, strong technology and strict quality control.

Our factory have been adhering to the business philosophy of "sincerity, quality and service" and strictly implementing the ISO9001 international quality management system. We regard quality as the life of our enterprise to be permanently vigorous, provide high-quality products and good services to customers at home and abroad.