Средняя модель QT6-15 автоматический блок делая машины кирпича цемента мостовой производственная линия с высоким

- Категория: Brick Making Machinery >>>

- Поставщик: Linyi,Dongyue,Building,Materials,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 35700.47 $* | 37485.47 $* |

| Aug-18-2025 | 35400.32 $* | 37170.25 $* |

| Jul-18-2025 | 29700.5 $* | 31185.21 $* |

| Jun-18-2025 | 34800.59 $* | 36540.29 $* |

| May-18-2025 | 30300.19 $* | 31815.84 $* |

| Apr-18-2025 | 34200.24 $* | 35910.4 $* |

| Mar-18-2025 | 33900.9 $* | 35595.90 $* |

| Feb-18-2025 | 33600.8 $* | 35280.96 $* |

| Jan-18-2025 | 33300.93 $* | 34965.42 $* |

Характеристики

Contact: Emily Dai WhatsApp(Wechat): 0086 15053957176 More than 25 years manufacturer of types block making machines, many model

for choose with different capacity!

if you have any request, Don't hesitate to contact me!

for choose with different capacity!

if you have any request, Don't hesitate to contact me!

Products Description

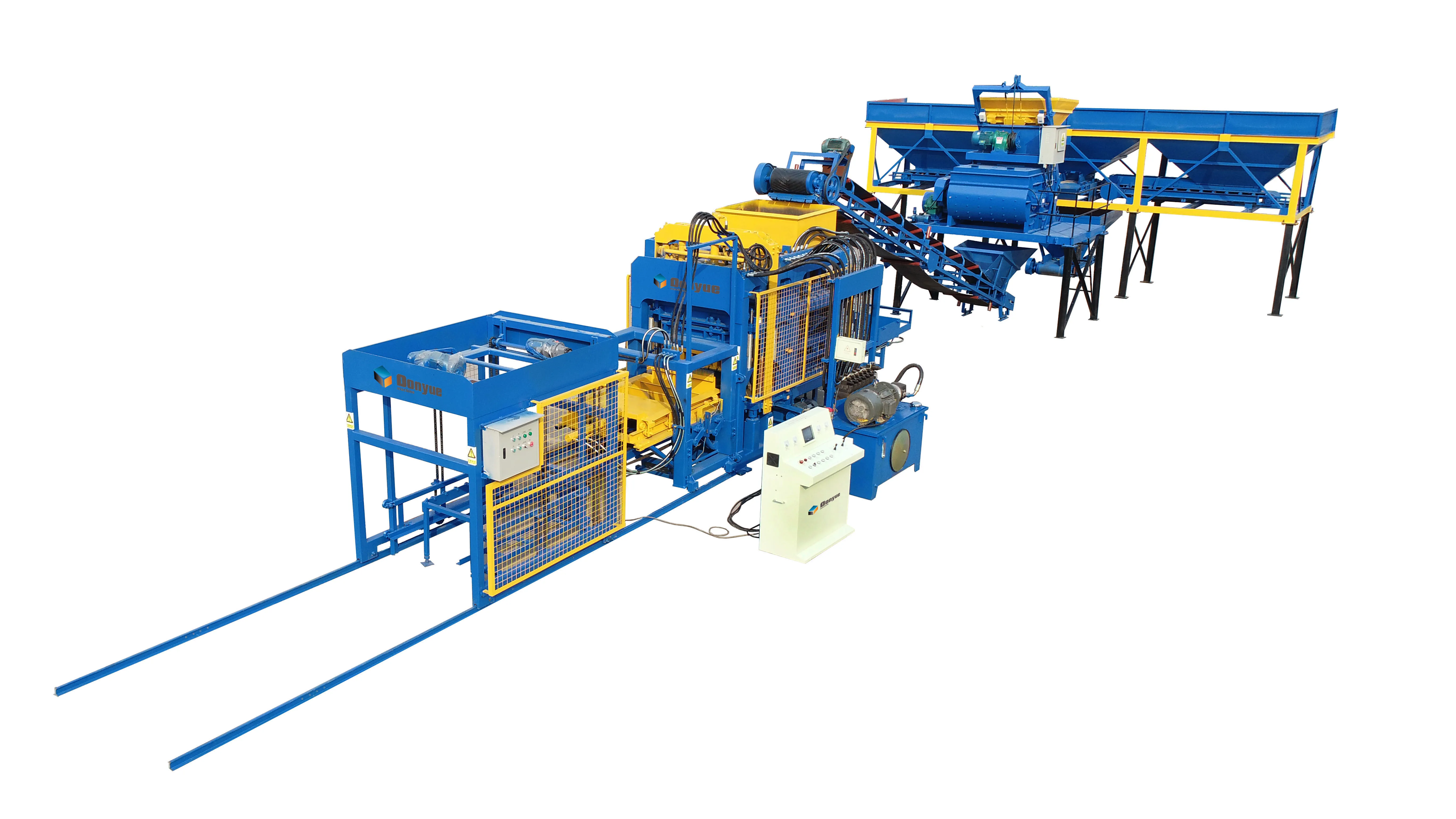

Middle model QT6-15 automatic block making machine brick cement pavement production line with great quality

1. More heavier host machine 85000kg

2. More stronger main structure with Reinforce

3. Famous brand motor and electrical components

4. Advanced technology in China

5. After-sales service team, worry-free after-sales

Main technical parameter | ||||||

Dimension of host machine | 3200*2300*2750mm | Host machine power | 45KW | |||

Weight of host machine | 8500kg | VIbratioon force | 80KN | |||

Moulding area | 1090*660mm | Models of mixer | JS500 | |||

Pallet size | 1150*720*25mm | Froming cycle | 15-20 seconds | |||

Theoretical production capacity | ||||||

Size(L*W*H), mm | pcs/mould | pcs/hour | pcs/ 8 hours | |||

400*100*200mm | 10 | 2400 | 19200 | |||

400*150*200mm | 8 | 1920 | 15360 | |||

400*200*200mm | 6 | 2160 | 17240 | |||

240*115*53mm solid block | 40 | 9600 | 76800 | |||

Paver:200*100*60mm | 27 | 4860 | 38880 | |||

Paver:200*163*60mm | 18 | 3240 | 25020 | |||

S paver 245*122.5*60mm | 18 | 3240 | 25020 | |||

Paver 250*250*60mm | 8 | 1440 | 11520 | |||

Paver 300*300*60mm | 6 | 1080 | 8640 | |||

1000*80*200mm curbstone | 6 | 1080 | 8640 | |||

1000*200*300mm curbstone 1000*180*300mm curbstone 1000*150*300mm curbstone | 2 | 360 | 2880 | |||

The block mold is customizable and replaceable to produce different kinds of blocks according to your requirement. | ||||||

Details Images

Middle model QT6-15 automatic block making machine brick cement pavement production line with great quality

1.Material and welding: All material and spare parts selected according to international CE standard, Carbon dioxide protection will assure whole line stable running.

2. Electric control system: We selected original Mitsubishi PLC combine with independent machine control system to assure stable and high-efficiency working status.

3.Switches and motor:Switched will use Japan Omron or France Schneider, motor will use Siemens or ABB band.

4.Hydraulic system: The machine adopting the advanced hydraulic molding technology, it can assure the block machine have stable and high-efficiency working status, and the blocks produced are of better quality,larger density and higher strength.

5.Block mould: Our block moulds are made of 16# manganese steel.Besides the good raw material, precise line cutting technology and 900ºC carburizing heat treatment technology are all adopted in the process of brick moulds production.Then the mould size error can be controlled within 0.002mm . The surface layer of the brick moulds get higher hardness (achieving HRC54-58) and better wear resistance.

6. Vibration system: The machine adopts the special technology to optimize the vibration shaft, so that the proportion of vibration is covered in the whole surface range, so the product quality is greatly improved and the noise is effectively reduced. The machine's unique fixed platform design forms can improve the molding speed and dimensional accuracy.

Production process

Production process

1. Material Batching and preparation Section: Raw materials are discharged to the mixer from three Hopper batching machine, as there is a hole under ground. The mixed raw materials are sent to the mixer.

2.Mixing Section: After being mixed evenly with water, raw material are unloaded to the block making machine through belt conveyor.

3.Block forming Section: Mixed raw material are then sent to the mould case. Under PLC computer intelligent control. Hydraulic transmission, vibration, shaping takes place.

4.Automatic Stacker Section: After demoulding ,green brick will be unloaded to the bamboo pallet.

5.Block Curing Section : Wet product will be conveyed through green block conveyor then to the stacker.

Finished blocks

Company Profile

CE certificate

SGS certificate

ISO9001 certificate

Packing&Delivery

Containers

For QT4A-15, QT5-15, QT6-15, QT8-15, QT10-15, QT12-15 need at least 2*40HQ containers, depends on order.