Литьевая формовочная машина/Тракторная литьевая машина/автоматическая машина с

- Категория: Metal Casting Machinery >>>

- Поставщик: Qingdao,Xinke,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 61880.69 $* | 64974.24 $* |

| Aug-16-2025 | 61360.80 $* | 64428.97 $* |

| Jul-16-2025 | 51480.90 $* | 54054.55 $* |

| Jun-16-2025 | 60320.38 $* | 63336.46 $* |

| May-16-2025 | 52520.97 $* | 55146.76 $* |

| Apr-16-2025 | 59280.3 $* | 62244.39 $* |

| Mar-16-2025 | 58760.26 $* | 61698.51 $* |

| Feb-16-2025 | 58240.34 $* | 61152.19 $* |

| Jan-16-2025 | 57720.34 $* | 60606.6 $* |

Характеристики

2022 New Arrival

Casting molding machine/tractor casting molding machine/manhole cover automatic molding machine

Name: Casting molding machine

Model: Z425

Full automatic horizontal flaskless molding machine is used to manufacture sand castings.

Automatic one-button operation, without professional workers each complete shape only need to press a start button (not under the core working condition), such as the need for the core of the workpiece, after the program selection, automatic stop, after the core is completed, press the die button, the program is automatically completed.

The molding machine adopts double-sided template, pneumatic sand feeding. Uniform hardness, flask closing high precision and adjustable sand thickness, easy replacement of template.

The hydraulic oil temperature control ensures the best running state of the equipment.

The molding machine adopts double-sided template, pneumatic sand feeding. Uniform hardness, flask closing high precision and adjustable sand thickness, easy replacement of template.

The hydraulic oil temperature control ensures the best running state of the equipment.

Main features

- Automatic modeling, no need for professional operation.

- Rapid production, a variety of existing conditions of the transformation scheme.

- The sand mold is stable and reliable, avoiding human interference.

- Old templates can be used to save mold costs.

- Can be continuous production, low operating cost.

- Independent research and development, convenient maintenance.

According to the existing conditions of various founders, we can design renovation schemes, maximize the use of existing furnaces, sites and sand treatment equipment, so that investors can get the maximum return with the minimum investment, improve casting quality and save high labor costs.

Application

The full automatic horizontal flaskless molding machine adopts way of horizontal molding, which is suitable for the production of small and medium-sized castings such as valves, mechanical parts, auto parts, hydraulic parts, pipe fittings, agricultural machinery parts, stove parts, brake discs,bearing caps, automobile castings, diesel castings, sewing machine castings, motor covers, water pump castings, etc.

It is suitable for the production of ductile iron and grey iron, ash, non-ferrous metals and other materials.

Advantages:

1. Flaskless molding operation.

2. Horizontal type, convenient for the core.

3. Fully automatic modeling, one-button operation, no professional workers needed.

4. Mold hardness can be adjusted according to different casting requirements, up to 85-90 degrees.

5. The height of the mold is adjustable, saving sand.

6. The mold quality is constant and uniform.

7. With advanced light curtain safety protection device.

8. Sand mould size:

700*600 mm, 600*500 mm or customized.

Main Specification of 2022 new arrival Casting molding machine

Product Name | 1000 | Green Sand Automatic Horizontal Parted Flaskless Shoot Squeeze Casting Molding Machine | Rear axde,brake drum,counter weight | ||

Sand size(mm) | 500*400*150/150/550*450*150/150 | ||||

5-10 | 1000 | 610*508*130-180/130-180/660*508*130-180/130-180 | Gray iron castings, counter weight for forklifts,loaders etc | ||

700*600*130-180/130-180/600*600*130-180/130-180 | |||||

Productivity (sec/pcs) | 36-40 sec/mold 90molds/h (Time does not contain the core setting) | ||||

Compaction ratio (Mpa) | 0.7-0.9 | ||||

Air consumption (m³/Min) | 1.6 | ||||

Work pressure (Mpa) | 8.5 | ||||

Power(Kw) | 15 | ||||

Sand consumption(T/h) | 10 | ||||

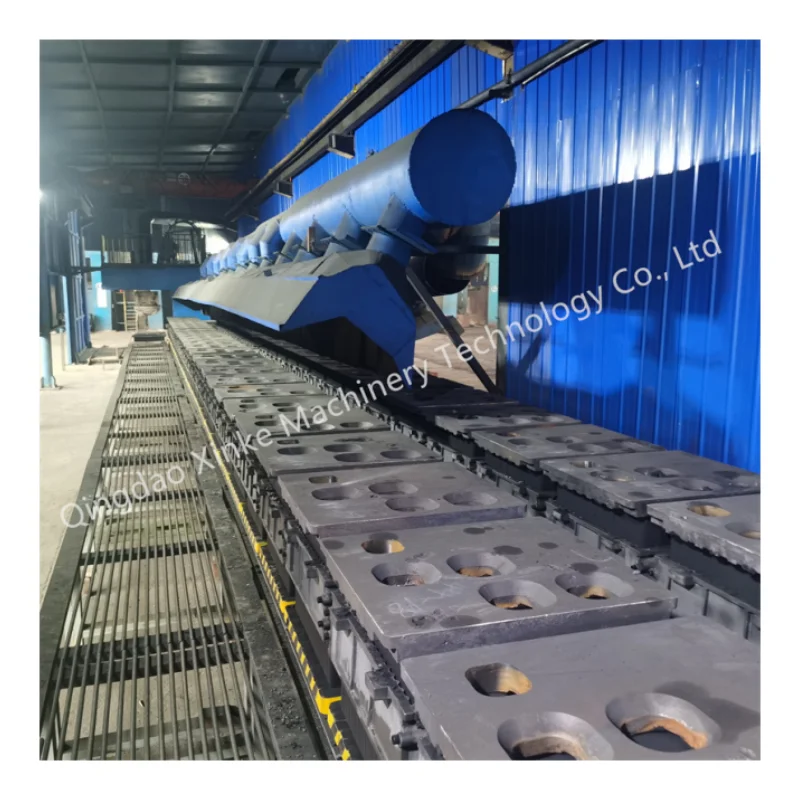

Photographing in Client's factory of Casting molding machine

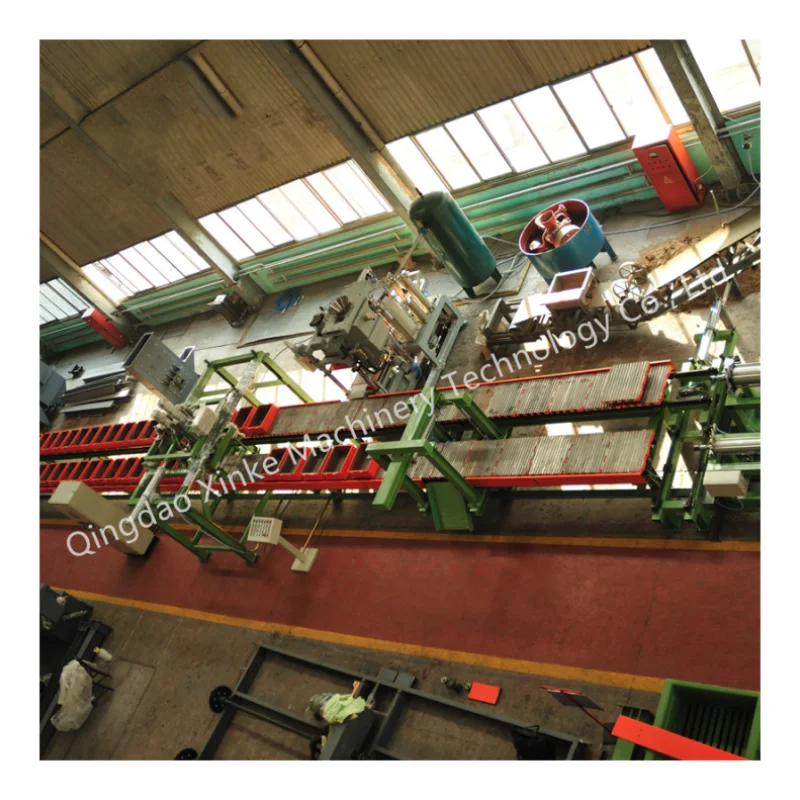

Installation of Casting molding machine

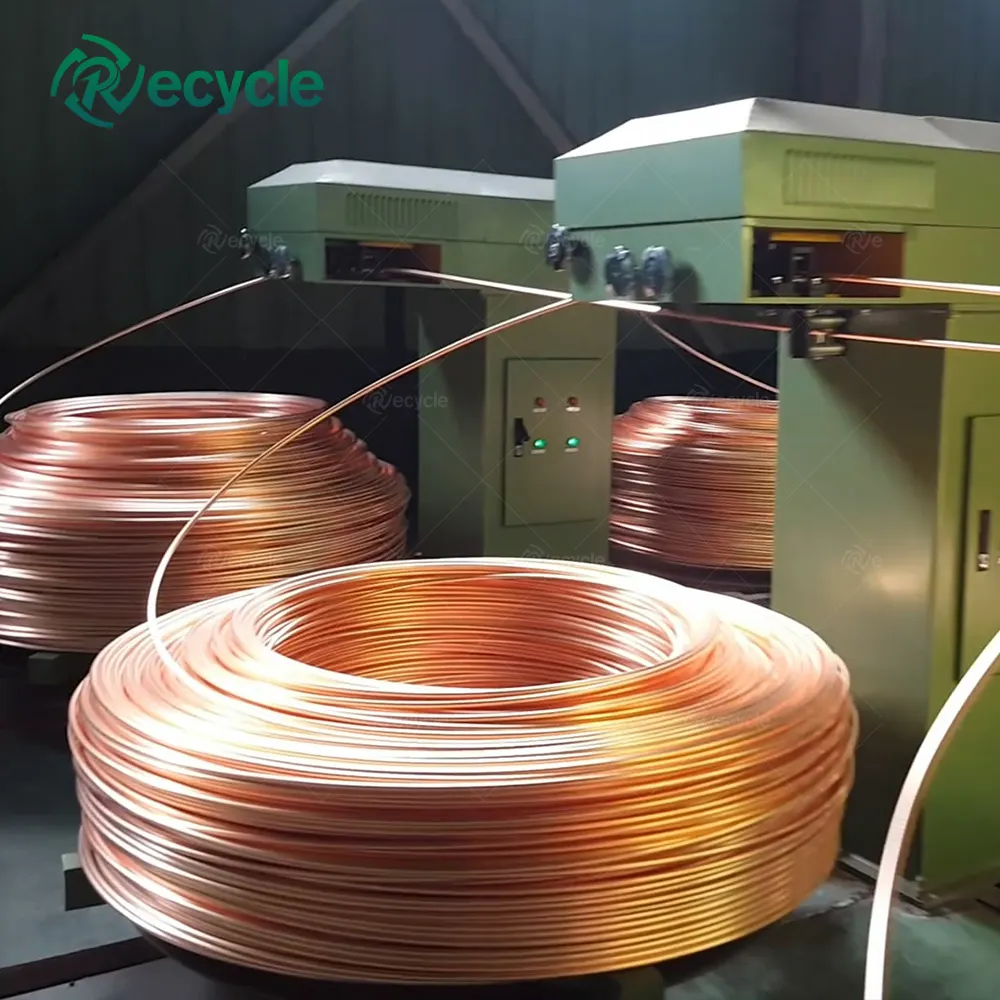

Casting of Casting molding machine

1.How many days do you need to produce this machine?

This is our standard machine and we have some in stock,can be delivered right now after your deposit.

2.What does your factory do regarding quality control?

We pay much more importance to quality from the very beginning to the end of production,Every machine will be fully assembled and carefully tested before shipment.

3.What's your machine quality guarantee?

Quality guarantee time is one year,We choose world famous brand components to keep our machine in perfect working condition.

4.Are you able to give installation and commissioning overseas?How long will it takes?

Yes,we supply overseas service, but customers needs to pay for the engineers fight tickets and hotel,food .Small machine usually takes about 20days.

This is our standard machine and we have some in stock,can be delivered right now after your deposit.

2.What does your factory do regarding quality control?

We pay much more importance to quality from the very beginning to the end of production,Every machine will be fully assembled and carefully tested before shipment.

3.What's your machine quality guarantee?

Quality guarantee time is one year,We choose world famous brand components to keep our machine in perfect working condition.

4.Are you able to give installation and commissioning overseas?How long will it takes?

Yes,we supply overseas service, but customers needs to pay for the engineers fight tickets and hotel,food .Small machine usually takes about 20days.

Похожие товары

Алюминиевые заготовки прокладок и по-прежнему для литья под давлением

US $18000-$200000

Литая машина для изготовления ювелирных изделий

US $339.71-$402.00