Складной дом ibr металлическая оцинкованная цинковая Кровельная Панель роликовая

- Категория: Tile Making Machinery >>>

- Поставщик: Anping,Cowan,Wire,Mesh,&,Machines,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 8889.3 $* | 9067.11 $* |

| Jul-17-2025 | 7209.42 $* | 7353.28 $* |

| Jun-17-2025 | 8749.55 $* | 8924.58 $* |

| May-17-2025 | 8679.90 $* | 8853.21 $* |

| Apr-17-2025 | 6929.92 $* | 7068.14 $* |

| Mar-17-2025 | 8539.60 $* | 8710.88 $* |

| Feb-17-2025 | 8469.93 $* | 8638.17 $* |

| Jan-17-2025 | 8399.60 $* | 8567.50 $* |

Характеристики

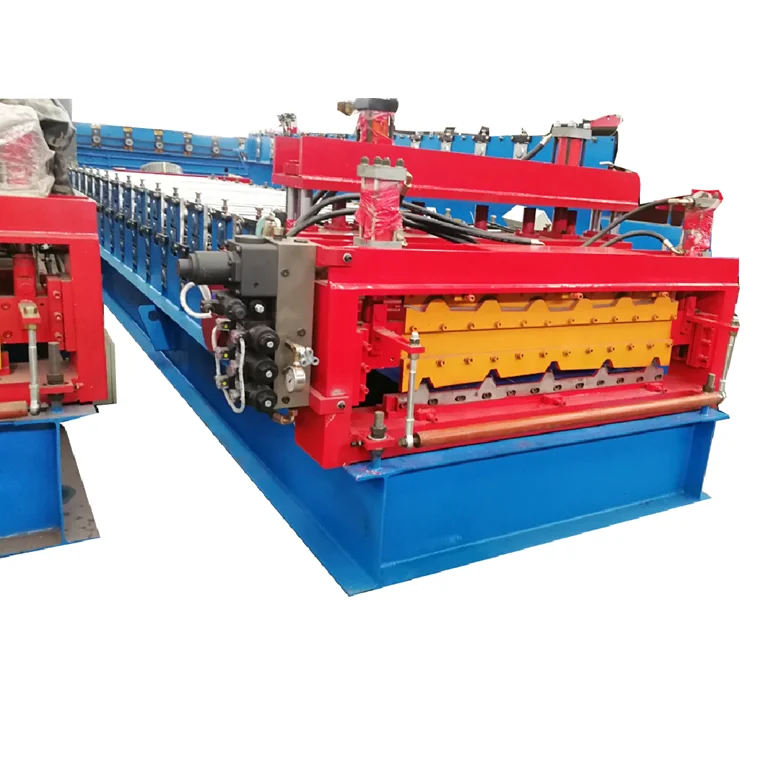

Making Metal Colored Roof Tile Forming Machine and roof panel machine

Product Description

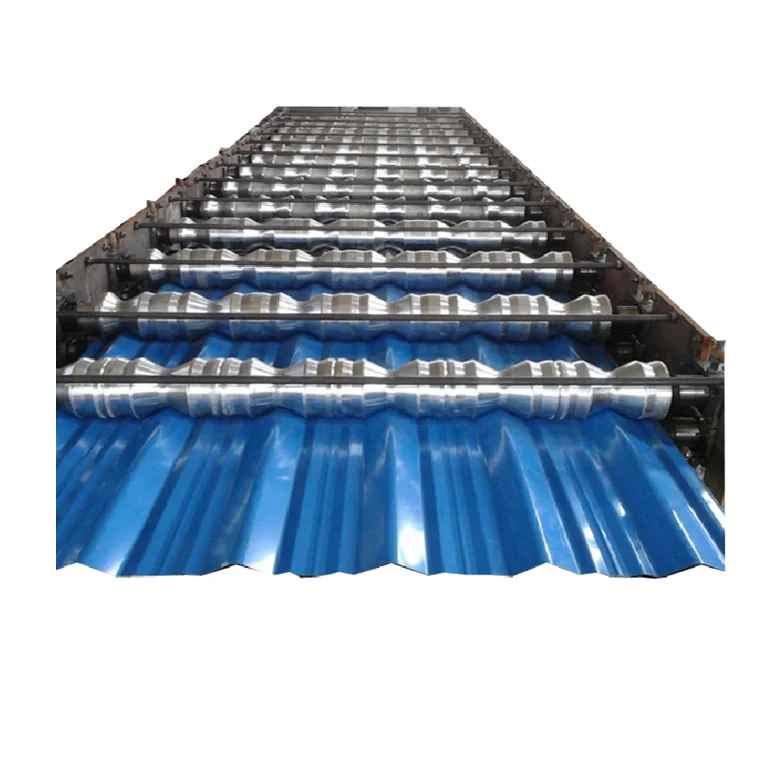

The finished product of Hydraulic Cutting And Pressing Glazed Metal Roof Tile Making Machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

| Hydraulic Cutting And Pressing Glazed Metal Roof Tile Making Machine | ||

| 1 | Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| 2 | Thickness of coil sheet | 0.3-0.8mm |

| 3 | Coil width | 1250mm |

| 4 | Effective width | 1000mm |

| 5 | Material of main frame | 400H steel structure, strong and durable |

| 6 | Diameter of Soild shaft | 70mm, high grade 45# steel |

| 7 | Roller | High grade 45# steel, quenched and tempered treatment, hard chrome plated 0.05-0.07mm |

| 8 | Thickness of middle plate | 18mm, 45# steel plate |

| 9 | Forming station | 23 rows |

| 10 | Drive type | By chain(1.0 inch), link bearing model 6210 |

| 11 | Power of main motor | 5.5 kw, Lichao, Shanghai, with reducer |

| 12 | Sidewall connection bar | 25mm, zinc plated |

| 13 | Forming speed | About 12-18m/min |

| 14 | Hydraulic pump station | 5.5 kw, 40# hydraulic oil |

| 15 | PLC | Mitsubishi, Japan |

| 16 | Material of razor blades | Cr 12, quenching 58-62℃ |

| 17 | Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

| 18 | Switch | CHNT |

| 19 | Frequency changer | SAJ |

Our products are used to produce in roof and wall building. It can be used in factories, houses, schools, hotels, shops and other construction sites.

Our Advantages

LARGE CNC MILLING MACHINE

Combined double layer building material machinery steel tile roofing sheet roll forming machine a unique plant in Hebei Province.It directly mills the entire frame. The milling machine can make the machine's large surface smoother and the machine is more perfect. Combined double layer building material machinery steel tile roofing sheet roll forming machine

SHOT BLASTING MACHINE

Combined double layer building material machinery steel tile roofing sheet roll forming machine can handle the entire machine frame or parts,making the rusty surface clean and smooth The surface of the product increases adhesion. Combined double layer building material machinery steel tile roofing sheet roll forming machine

NEW CNC MILLING

Combined double layer building material machinery steel tile roofing sheet roll forming machine make the backboard of purlin machine, also make the holes on backboard. This milling machine can milling the backboard more level, hole place is more precious. This can make the roller more level after installing,and then the purlin will be more straight.

Mechanical process

Combined double layer building material machinery steel tile roofing sheet roll forming machine line, have high precious CNC grinders and milling machines,to make the rollers and shafts of the machine.After produce, have professional engineer to check if these are qualified.

From one roller to one machine, we do every step carefully to make sure the quality.

ELECTRICAL CONTROL

All the control system of our machines we

make by ourselves. we have a professional engineer to design and make the control system. Combined double layer building material machinery steel tile roofing sheet roll forming machine can make sure the after-sale service, when customer have problem with control, we can solve it timely.

ENVIRONMENT FRIENDLY SPRAYING EQUIPMENT

Combined double layer building material machinery steel tile roofing sheet roll forming machine electrostatic spraying equipment meets the environmental protection regulations of the Chinese government and guarantees the delivery time of the machine.

FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.

Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.