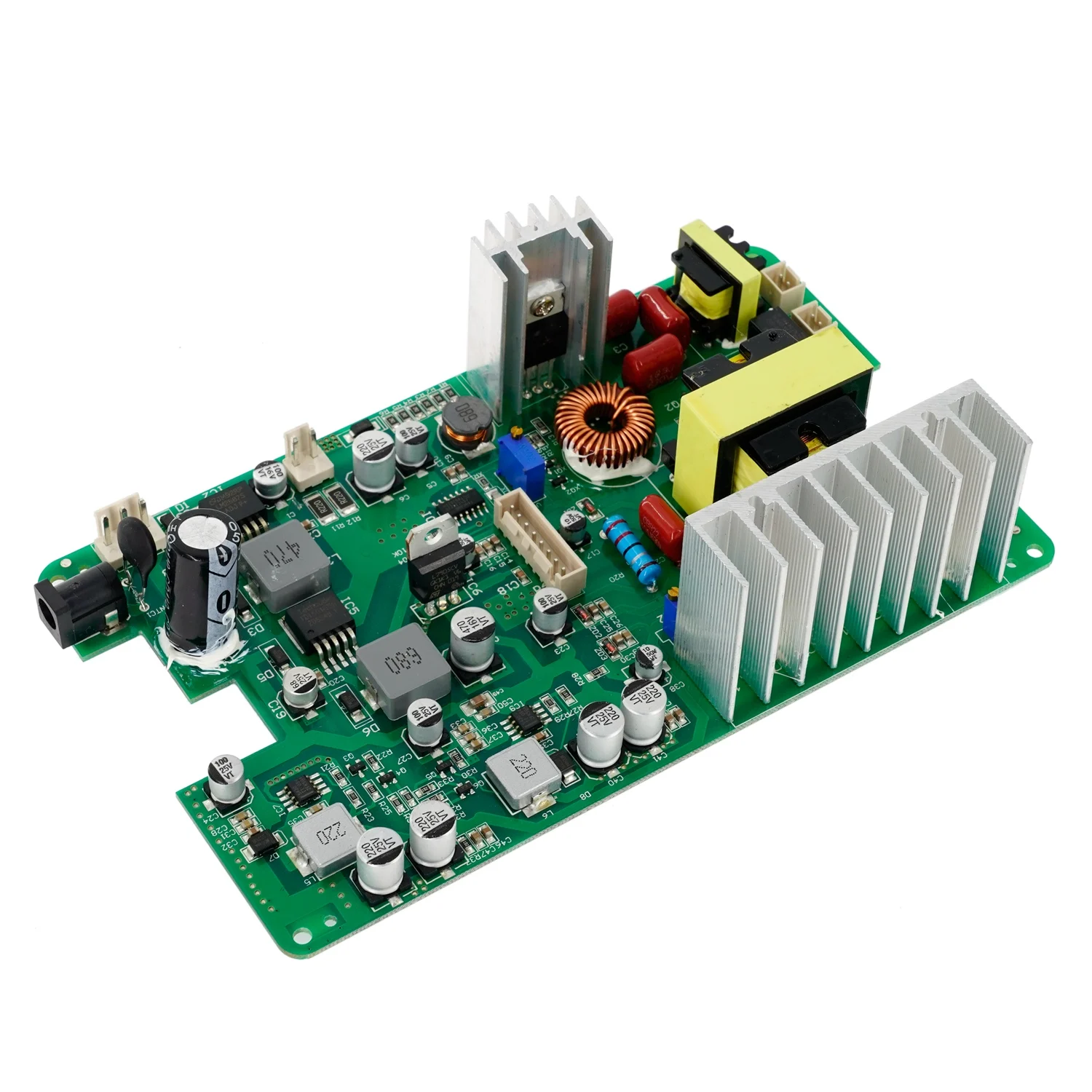

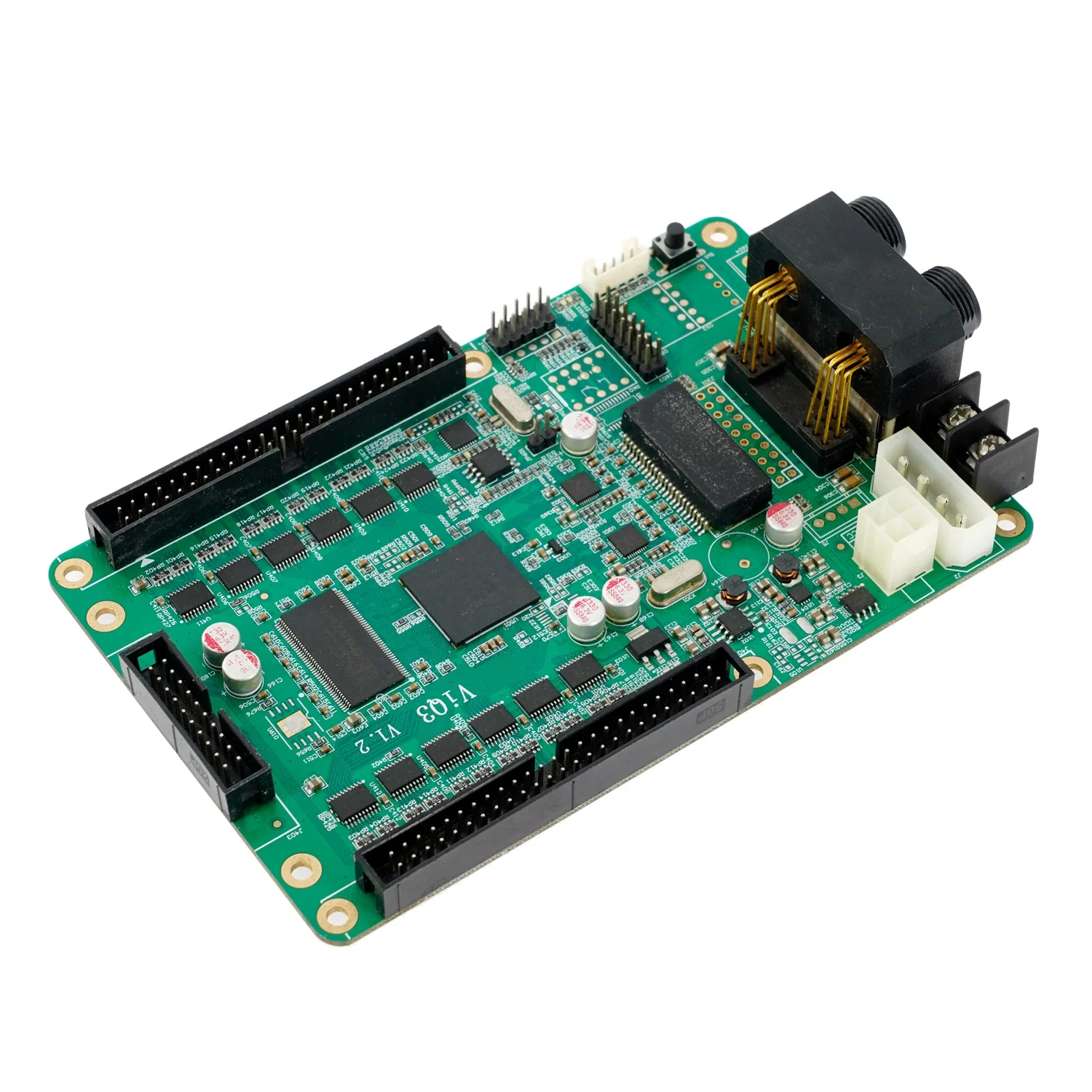

Печатная плата на заказ сборка печатной платы mp3-аудио плеер

- Категория: Rigid PCB >>>

- Поставщик: Shenzhen,Jingxin,Electronic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.1 $* | 0.45 $* |

| Aug-16-2025 | 0.28 $* | 0.88 $* |

| Jul-16-2025 | 0.75 $* | 0.60 $* |

| Jun-16-2025 | 0.71 $* | 0.88 $* |

| May-16-2025 | 0.27 $* | 0.86 $* |

| Apr-16-2025 | 0.66 $* | 0.81 $* |

| Mar-16-2025 | 0.78 $* | 0.6 $* |

| Feb-16-2025 | 0.28 $* | 0.48 $* |

| Jan-16-2025 | 0.98 $* | 0.82 $* |

Характеристики

Company Profile

OUR CERTIFICATE

Why Choose Us

*From BOM list matching, components supply to PCB Assembly, all completed in Allchips ;

*BOM IN ONE BOX (our BOM list automatic matching system ), matching and standardizing BOM list in 4 hours ;

*SMT Prototype in 24 hours ;

*Pilot production ( under 500 sets ) in 3-7 days ;

*AOI inspection, IPQC inspection, sight inspection, simple function inspection, full function inspection ( with customers’ guidance ), etc before shipment ;

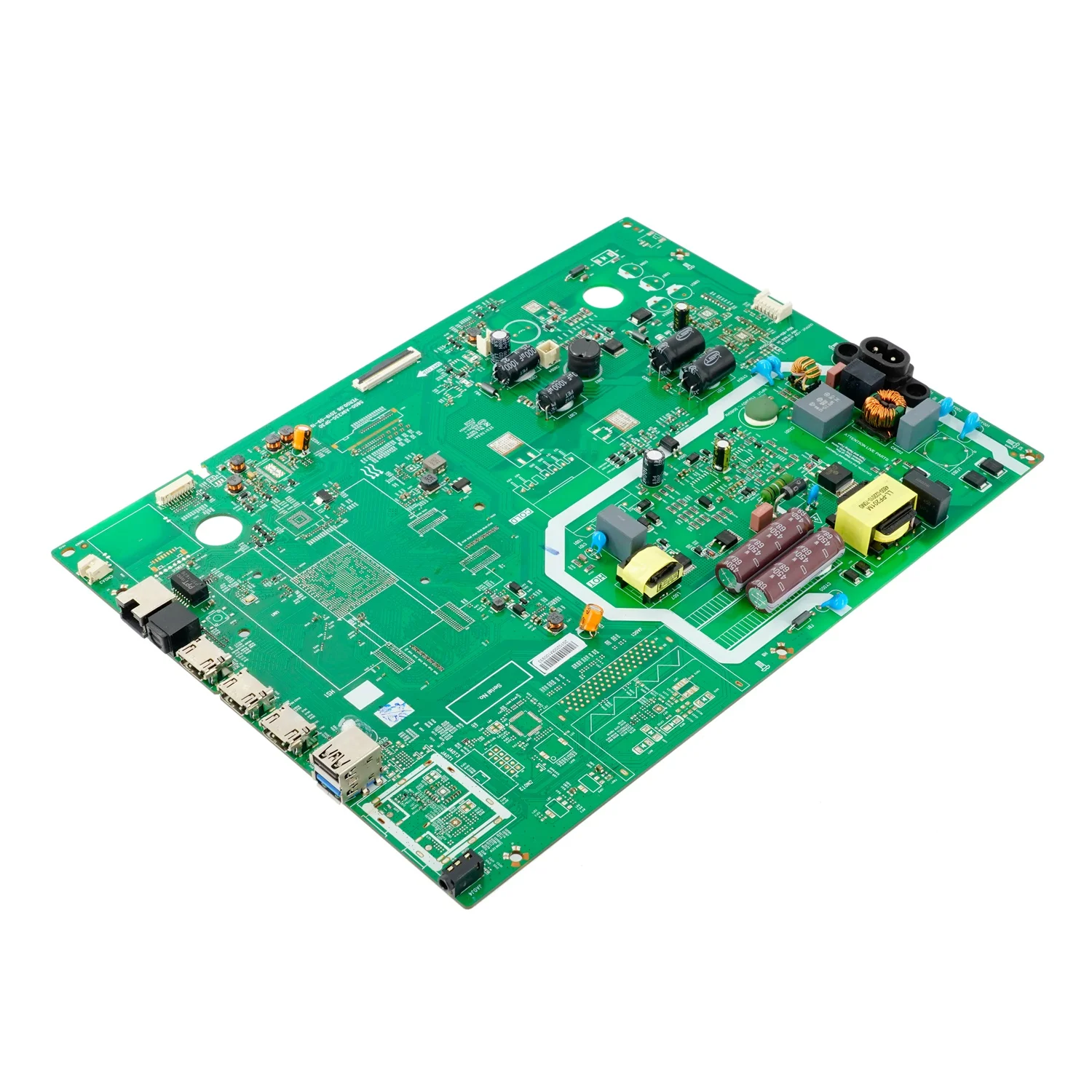

Products Description

Term | Detailed Specification of PCBA Board Manufacturing |

Layer | 1-30 layer |

Material | FR-4, CEM-1, CEM-3, Hight TG, FR4 Halogen Free, FR-1, FR-2, Aluminum |

Board thickness | 0.4mm-4mm |

Max.finished board side | 1020mm*1000mm |

Min.drilled hole size | 0.25mm |

Min.line width | 0.10mm(4mil) |

Min.line spaceing | 0.10mm(4mil) |

Surface finish/treatment | HASL/HASL lead free,Chemical tin,Chemical Gold,Immersion gold Inmersion Silver/Gold,Osp,Gold Plating |

Copper thickness | 1/2OZ 1OZ 2OZ 3OZ |

Solder mask color | green/black/white/red/blue/yellow |

Inner packing | Vacuum packing,Plastic bag |

Outer packing | Standard carton packing |

Hole tolerance | PTH:±0.076,NTPH:±0.05 |

Certificate | ISO9001,ISO14001,ROHS,CQC |

Profiling Punching | Routing,V-CUT, Beveling |

Assembly Service | Providing OEM service to all sorts of printed circuit board assembly |

Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

Various sizes like 1206,0805,0603 components SMT technology | |

ICT(In Circuit Test),FCT(Functional Circuit Test) technology | |

PCBA Assembly With CE,FCC,Rohs Approval | |

Nitrogen gas reflow soldering technology for SMT | |

High Standard SMT&Solder Assembly Line | |

High density interconnected board placement technology capacity | |

Quote&Production Requirement | Gerber File or PCBA File for Bare PCBA Board Fabrication |

Bom(Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly | |

To reduce the quote time, please provide us the full part number for each components,Quantity per board also the quantity for orders. | |

Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

OEM/ODM/EMS Services | PCBA, PCBAAassembly: SMT & PTH & BGA |

PCBA and enclosure design | |

Components sourcing and purchasing | |

Quick prototyping | |

Plastic injection molding | |

Metal sheet stamping | |

Final assembly | |

Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

Custom clearance for material importing and product exporting | |

Other PCBA Assembly Equipment | SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

Reflow Oven: FolunGwin FL-RX860 | |

Wave Soldering Machine: FolunGwin ADS300 | |

Automated Optical Inspection (AOI): Aleader ALD-H-350B,X-RAY Testing Service | |

Fully Automatic SMT Stencil Printer: FolunGwin Win-5 |

Main PCBA Application

Smart Home Devices PCBA

Telecom PCBA Assembly

BLE & WIFI Module PCBA

IoT Smart Sensor PCBA Assembly

Home Appliance PCBA Assembly

Industrial Control PCBA Assembly

Medical Devices PCBA Assembly

Security-Device-PCBA

LoRa Products Assembly

Payment & Energy Products PCBA

Wearable Devices Assembly

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCBA Assembly With CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

Production Process

Our services

Quick-turn Prototyping

Fast-turn around 24 hours electronic print circuit board prototype Quick prototype turnkey electronic print circuit board Assembly

within 7 days High end Manufacturer: Rigid, Flex,

Rigid-Flex, HDI, Metal Core, 10-40 layers etc. On-Demand Fabrication

Strong Supply Chain Management

Consist of wide qualified distributor and huge selection in-stock. Components are ready to Ship or Assembly

100,000+ Parts In-stock components

2000m² Component Warehouse

800+ Qualified suppliers and vendors

50+ Experts Procurement Team

20+ sec Instant Result

7,000,000+ Parts Real-time Stock & Price

within 7 days High end Manufacturer: Rigid, Flex,

Rigid-Flex, HDI, Metal Core, 10-40 layers etc. On-Demand Fabrication

Strong Supply Chain Management

Consist of wide qualified distributor and huge selection in-stock. Components are ready to Ship or Assembly

100,000+ Parts In-stock components

2000m² Component Warehouse

800+ Qualified suppliers and vendors

50+ Experts Procurement Team

20+ sec Instant Result

7,000,000+ Parts Real-time Stock & Price

Prototyping (Quick-turn available)

Standard electronic print circuit board 1-10 layers FR4 · Originalbuild time 72h + shipping time 48h ·Urgentbuild time 48h

+shipping time 48h · ExtraUrgentbuild time 24h + shipping time 24h Advanced electronic print circuit board (10-40 layers, HDI,

Military etc.) · Originalbuild time 10-12 Days +shipping time 48h

Volume Production · Small volume & Middle volume · Competitive Price · Min. Board Thickness 0.2mm · Min. Trace/Spacing 3.5mil ·

Quick-turn Available

Full-service Turnkey electronic print circuit board Assembly Solution electronic print circuit board manufacturing,components

sourcing and in-house assembly, whole project management available

+shipping time 48h · ExtraUrgentbuild time 24h + shipping time 24h Advanced electronic print circuit board (10-40 layers, HDI,

Military etc.) · Originalbuild time 10-12 Days +shipping time 48h

Volume Production · Small volume & Middle volume · Competitive Price · Min. Board Thickness 0.2mm · Min. Trace/Spacing 3.5mil ·

Quick-turn Available

Full-service Turnkey electronic print circuit board Assembly Solution electronic print circuit board manufacturing,components

sourcing and in-house assembly, whole project management available

Packing and shipping

Prototyping (Quick-turn available)

Our company is not only trying to give customers a good product but also pay attention to offering a complete and safe package.And

here we prepare some personalized services for all the orders.

Common packaging:

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

Shipping:

1.Confirming your shipping address is correct before delivery

2.Orders processed timely after the payment verification

3.Professional package. No worry about goods breakage.

4.Service transit time is upon different carrier, may vary particularly during holiday.

here we prepare some personalized services for all the orders.

Common packaging:

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

Shipping:

1.Confirming your shipping address is correct before delivery

2.Orders processed timely after the payment verification

3.Professional package. No worry about goods breakage.

4.Service transit time is upon different carrier, may vary particularly during holiday.

FAQ

Q1. What is needed for quotation?

1.Gerber file & Bom list.

1.Gerber file & Bom list.

2. Clear pics of pcba or pcba sample for us.

3.Test method for PCBA.

Q2. What file formats do you accept for production?

1. Gerber Files (Eagle and electronic print circuit board File are available).

2. BOM list. (Excel(PDF, WORD, TXT)

3. Clear pictures of PCBA or PCBA samples to us.

4. Pick N Place file.

5. Test procedure for PCBA.

Q3. Are my files safe?

Your files are held in complete safety and security. We protect the intellectual property for our customers are never shared with any third parties.

Q4. MOQ?

There is no MOQ. We are able to handle small as well as large volume production with flexibility.

Q5. Shipping cost?

The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the freight.

Q6. How can you ensure the quality of the PCBs?

Our PCBs are 100% test including Flying Probe Test, E-test and AOI.

Q7. Can we visit your company?

No problem.You are welcome to visit us in Shenzhen.

Q2. What file formats do you accept for production?

1. Gerber Files (Eagle and electronic print circuit board File are available).

2. BOM list. (Excel(PDF, WORD, TXT)

3. Clear pictures of PCBA or PCBA samples to us.

4. Pick N Place file.

5. Test procedure for PCBA.

Q3. Are my files safe?

Your files are held in complete safety and security. We protect the intellectual property for our customers are never shared with any third parties.

Q4. MOQ?

There is no MOQ. We are able to handle small as well as large volume production with flexibility.

Q5. Shipping cost?

The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the freight.

Q6. How can you ensure the quality of the PCBs?

Our PCBs are 100% test including Flying Probe Test, E-test and AOI.

Q7. Can we visit your company?

No problem.You are welcome to visit us in Shenzhen.