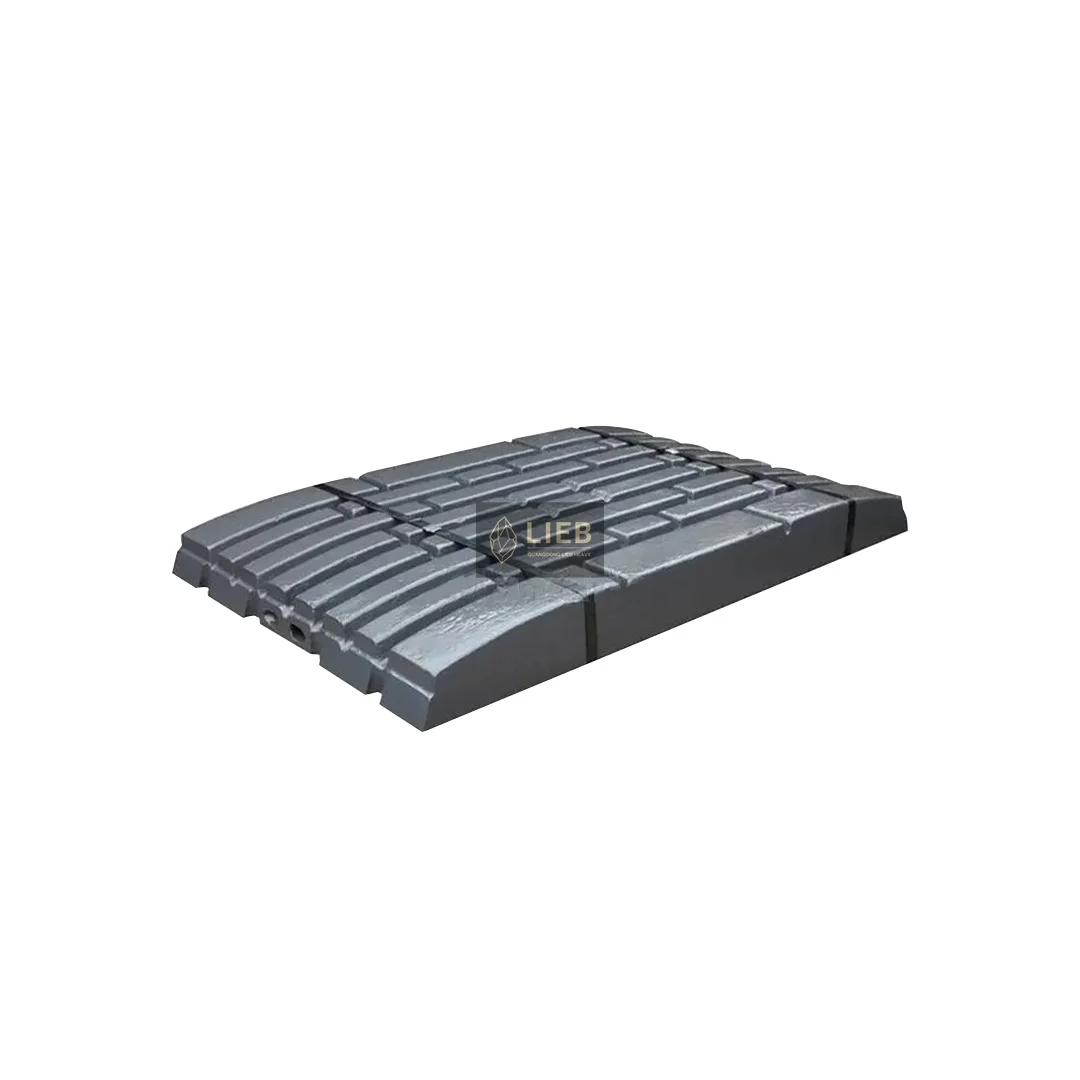

Щековая дробилка с фиксированным марганецем износостойкие детали пластина вкладыш зубные пластины щековая запасные

- Категория: Mining Machine Parts >>>

- Поставщик: Guangdong,Lieb,Heavy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 1.12 $* | 1.1 $* |

| Jul-19-2025 | 1.81 $* | 1.50 $* |

| Jun-19-2025 | 1.33 $* | 1.53 $* |

| May-19-2025 | 1.64 $* | 1.55 $* |

| Apr-19-2025 | 1.50 $* | 1.2 $* |

| Mar-19-2025 | 1.19 $* | 1.94 $* |

| Feb-19-2025 | 1.97 $* | 1.10 $* |

| Jan-19-2025 | 1.79 $* | 1.87 $* |

Характеристики

Product Description

In the crushing work for jaw crusher, the most consumed part of is the crusher jaw plate. The wear speed of the upper and lower parts of jaw plate is different. The lower part wears faster than the upper part. When the crusher works, the jaw plate directly collision with material and bears the huge crushing force and the friction of the material, the service life of the tooth plate is directly related to the working efficiency and production cost of the jaw crusher.

Application Machine: All kinds of jaw crusher.

Applicable Materials:River pebble, granite, basalt, iron ore, limestone, quartz, iron ore, gold ore, copper ore, etc.

Working site:sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material:

Following is our normal material component,we also can customize as your request.

Application Machine: All kinds of jaw crusher.

Applicable Materials:River pebble, granite, basalt, iron ore, limestone, quartz, iron ore, gold ore, copper ore, etc.

Working site:sand-gravel yard, mine mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

Material:

Following is our normal material component,we also can customize as your request.

Chemical Component:

Material | Chemical Composition(%) | Mechanical Property | ||||||||

C | Si | Mn | Cr | Ak/cm | HB | |||||

Mn13Cr2 | 1.1~1.4 | 1.7~2.2 | 12~15 | 1.7~2.2 | >140 | ≤220 | ||||

Mn18Cr2 | 1.1~1.4 | 1.7~2.2 | 17~19 | 1.8~2.2 | >140 | ≤230 | ||||

The main characteristics of jaw plate are good toughness and good resistance to deformation and hardening.

The jaw plate is made of Mn13Cr2 pouring material. We add a certain amount of chromium material in the high manganese steel, improving the hardness, in the meantime, doing water toughening treatment also improve its tensile strength, toughness, plasticity and non-magnetic, so that the jaw plate is more durable.

The jaw plate is made of Mn13Cr2 pouring material. We add a certain amount of chromium material in the high manganese steel, improving the hardness, in the meantime, doing water toughening treatment also improve its tensile strength, toughness, plasticity and non-magnetic, so that the jaw plate is more durable.

Specification

Available models for jaw crusher parts | ||||

Metso | C series | C80,C96,C106,C116,C120,C130,C150,C160,C200 | ||

Sandvik | CJ series | CJ815,CJ615,CJ613,CJ612,CJ412,CJ411,CJ409,CJ211 | ||

Terex | JC/JS/JW series | JC5460,JC3660,JS4552,JS3750,JC2260,JW55,JW42 | ||

Telsmith | H series | H2238,H2550,H3244,H3450,H4448,H5060,H3042,H3055,H3648,H3258,H3858 | ||

Shanbao | PE series | PE150x250, PE250x400,PE400x600,PE500x750,PE600x900, PE750x1050, PE900x1200,PE100x1200,PE1200x1500,PE1500x1800 | ||

PEX series | PEX250x750,PEX250x1000,PEX250x1200,PEX300x1300 | |||

Company Profile

Guangdong Lieb Heavy Technology Co., Ltd. is a professional mining crusher wear parts manufacturer integrating design, development, manufacturing and sales. Our company was founded in 1985 and covers an area of 40,000 square meters.

Our technical equipment is at the leading domestic level, with a full set of steel casting equipment, large-scale processing equipment and related testing methods, and advanced water glass modeling and lost foam casting technology. The surface of our product is smooth and the internal structure is uniform, the annual production capacity is more than 20,000 tons.

Guangdong Lieb has been producing in this industry for more than 35 years, with strong technical advantages and rich experience in the production of wear-resistant castings. We specialize in the production of wear-resistant parts for crushers such as high-manganese steel wear-resistant castings, high-chromium wear-resistant castings, and carbon alloy steel castings.

Our technical equipment is at the leading domestic level, with a full set of steel casting equipment, large-scale processing equipment and related testing methods, and advanced water glass modeling and lost foam casting technology. The surface of our product is smooth and the internal structure is uniform, the annual production capacity is more than 20,000 tons.

Guangdong Lieb has been producing in this industry for more than 35 years, with strong technical advantages and rich experience in the production of wear-resistant castings. We specialize in the production of wear-resistant parts for crushers such as high-manganese steel wear-resistant castings, high-chromium wear-resistant castings, and carbon alloy steel castings.

Our products can be used for spare and wear parts of many crusher brands (Sandvik, Metso, Geoffran, Leimen, etc.).

Our products are exported to more than 30 countries around the world, such as the United States, Russia, Mexico, Chile,

Peru,Australia, Japan, South Korea, Thailand, South Africa, etc.

Guangdong Lieb is committed to providing global customers with a one-stop solution for satisfactory products and best services.

Our mission is to provide our customers with the highest quality replacement parts, assemblies and services to improve life cycle performance and save costs. We look forward to being your best partner, working hand in hand with you and growing together.

Our products are exported to more than 30 countries around the world, such as the United States, Russia, Mexico, Chile,

Peru,Australia, Japan, South Korea, Thailand, South Africa, etc.

Guangdong Lieb is committed to providing global customers with a one-stop solution for satisfactory products and best services.

Our mission is to provide our customers with the highest quality replacement parts, assemblies and services to improve life cycle performance and save costs. We look forward to being your best partner, working hand in hand with you and growing together.

Process Flow

Pakaging And Shipping

Certifications

FAQ

Q1: Are you crusher wear parts manufacturer?

A: Yes, we have been produced the crusher wear parts for more than 35 years.

Q2: Which country have your products been exported?

A: We have been exported business for 10 years and we have lots of customers and agents in the world, such as the United States,Russia, Mexico, Chile, Peru, Australia, Japan, South Korea, Thailand, South Africa etc.

Q3: What's the delivery time ?

A: Generally it is 7-10 days if the goods are in stock. For customize, it will take 30 to 60 days after receiving your advance

payment. The specific delivery time depends on the items and the quantity of your order.

Q4. If I need the complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and offer you related professional advises as per your

requirements. We had already built many mining projects in China & Overseas.

Q5. Do you accept OEM business?

A: Yes, we are OEM supplier.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

A: Yes, we have been produced the crusher wear parts for more than 35 years.

Q2: Which country have your products been exported?

A: We have been exported business for 10 years and we have lots of customers and agents in the world, such as the United States,Russia, Mexico, Chile, Peru, Australia, Japan, South Korea, Thailand, South Africa etc.

Q3: What's the delivery time ?

A: Generally it is 7-10 days if the goods are in stock. For customize, it will take 30 to 60 days after receiving your advance

payment. The specific delivery time depends on the items and the quantity of your order.

Q4. If I need the complete mineral processing line, can you help us to build it?

A: Yes, we can help you combine a complete mineral processing line and offer you related professional advises as per your

requirements. We had already built many mining projects in China & Overseas.

Q5. Do you accept OEM business?

A: Yes, we are OEM supplier.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Похожие товары

Буровое долото из карбида вольфрама 8 1/2 "IADC 537 637 tci tricone

US $200.00-$520.00

Буровая установка поворотного типа

US $100.00-$200.00