Латунные медные ФОСФОРНЫЕ бронзовые штамповочные детали электрические контакты

- Категория: Fabrication Services >>>

- Поставщик: Wenzhou,Saijin,Import,And,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.17 $* | 0.32 $* |

| Aug-16-2025 | 0.2 $* | 0.33 $* |

| Jul-16-2025 | 0.3 $* | 0.67 $* |

| Jun-16-2025 | 0.53 $* | 0.67 $* |

| May-16-2025 | 0.7 $* | 0.87 $* |

| Apr-16-2025 | 0.24 $* | 0.39 $* |

| Mar-16-2025 | 0.53 $* | 0.9 $* |

| Feb-16-2025 | 0.72 $* | 0.27 $* |

| Jan-16-2025 | 0.98 $* | 0.35 $* |

Характеристики

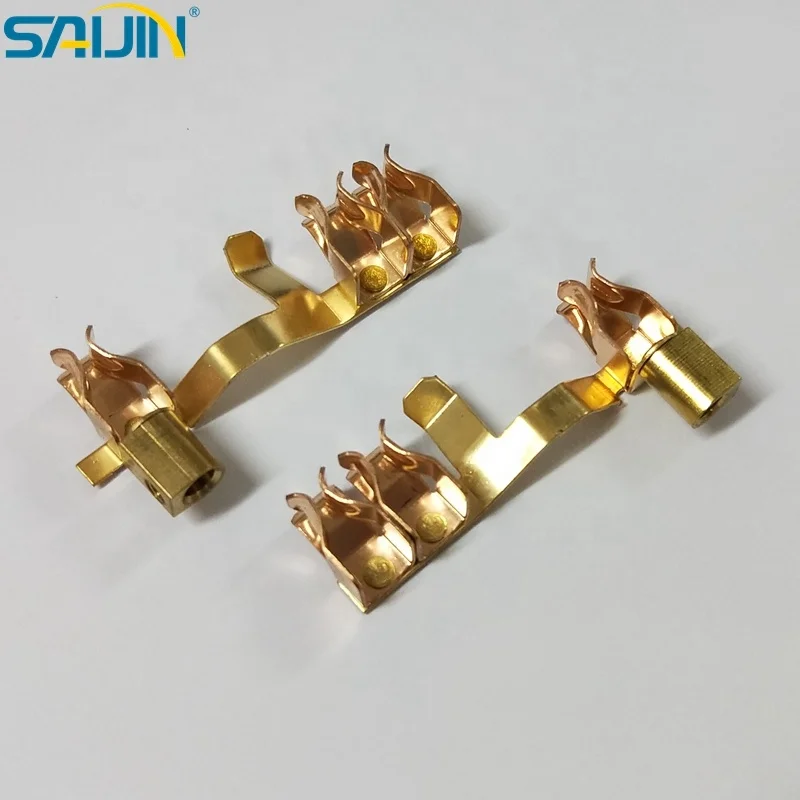

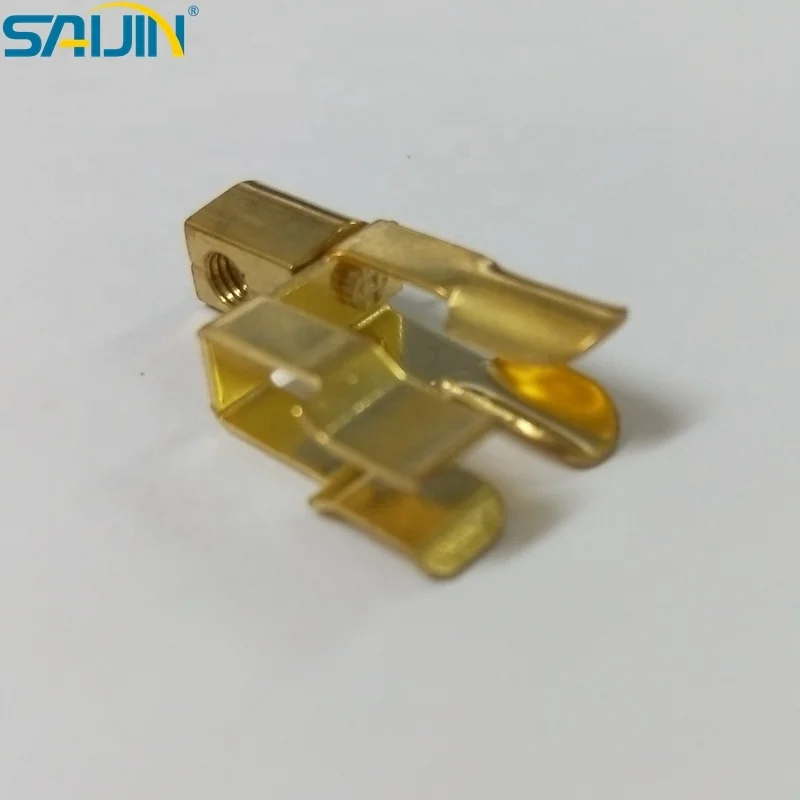

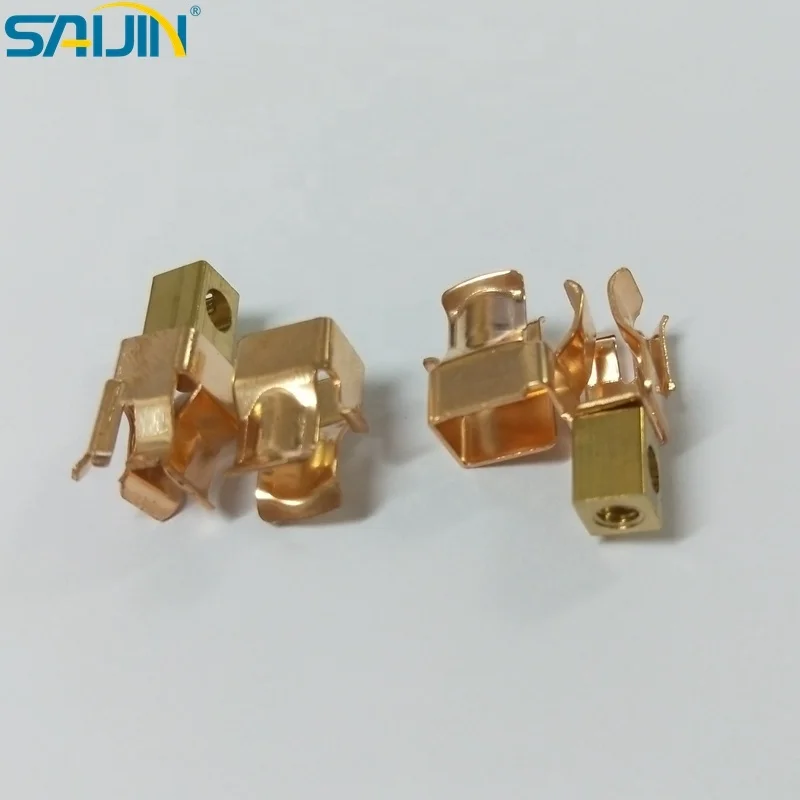

Brass copper phosphor bronze stamping part electrical contacts of socket switch

In-Die Staked Electrical Contacts

Wenzhou SAIJIN 's autostaking operation houses high speed high precision stamping presses, which produce in-die staked terminals, springs, and other electrical contact assemblies. In the in-die staking process, bimetal or solid contact rivets feed from a feeder system into the progressive stamping die. The stamping die then stakes the rivet into place and simultaneously produces the completed part.

Autostaked parts are more consistent in quality than semiautomatic or hand staked parts. And autostaking production rates are thousands of parts per hour, which makes it a cost-effective assembly technology.

We make our own bimetal and solid cold headed electrical contact rivets in our SAIJIN factory , cold forming facility.

In our autostaking operation in SAIJIN, China, we have complete toolroom. We design and make our own dies and spares. All of our autostaking tools are "Class A" dies, designed for high precision stamping, so they will run consistently for millions of parts.

For lower production volumes or for prototyping, we offer low volume hand or semiautomatic production. In these cases, the dies are less expensive than the high speed automation dies.

Our production is controlled and supported by our quality system, which is certified to ISO9001: 2008, and is compliant with the automotive specific clauses of TS 16949 including PPAP, APQP, and FMEA.

Our production is controlled and supported by our quality system, which is certified to ISO9001: 2008, and is compliant with the automotive specific clauses of TS 16949 including PPAP, APQP, and FMEA.

We can help with part design.

| Product Description | Brass copper phosphor bronze stamping part electrical contacts of socket switch | ||

| Capabilities Applied/Processes | Progressive Die Metal Stamping

| ||

| Equipment Used to Manufacture Part | 45 Ton Punch Press Cold Heading Toggle | ||

| Test Equipment | Hardness tester,Chemical analysis,Digital Measuring Projector, Dynamic Balancing Tester, Plating Tester | ||

| Tightest Tolerances | Flatness of ±0.05 | ||

| Material Used | Terminal: Brass-CDA260,Copper ,Phosphor copper ,Beryllium Copper Rivet:

| ||

| Surface Treatment | Silver/Zinc/Nickel/Tin/Chrome Plating, Pickling, Powder Coating,Hot Galvanized,Polishing,Brushing, etc. | ||

| In process testing/inspection performed | Full Dimensional Contact Torque | ||

| Features | Customized Design, Small Order Allowed, Sample Product Available, Competitive Price | ||

| Industry for Use | Automotive Switch , Socket, Relay | ||

| Delivery Location | China | ||

| Standards Met | Customer supplied print, 2D,3D CAD Drawing | ||

| Product Name | Brass copper phosphor bronze Home Types of electrical fittings |

Product scan:electrical fittings,copper contacts,electrical outlet contacts

How to produce:

Electrical contacts-metal stamping type Characteristic:

There are mainly three kinds of Contact spring :

(1) Riveting Parts: contact is riveted on copper component

(2) Welding Parts: sheet contact is welded on copper component

(3) Stamping Parts: precious clad metal is stamped into contact bridge component

(4).Certification: ISO9001, SGS, RoHS

(5).Material: Brass ,Stainless steel etc

(6).Type: riveting parts, stamping parts

Application:

Contact Components are widely used in low voltage electrical appliances and households, such as Switch Sockey, Relay, Thermal Controller Circuit Breaker Contactor Controller Timer, etc.

Inner package:plastic bag, Outer package: carton ,Then put into pallet

Customer design are welcome!

Our Service:

1) You inquiry will be replied within 24hours

2) Well-trained and experienced staffs to answer all your enquires in fluent English

3) OEM & ODM

4) Protect your sales area, ideas of design and all your private information

- Customized sizes and materials are welcome

- OEM orders are welcome

FREE SAMPLE can be sent for your evaluation!

Samples policy:

-1. We accept sample order for testing our quality.

-2. Sample charged will be higher than our offer, negotiability!

-3. Charge sample offered depends on customer’s design

-4. Shipping cost need to pay by customers

-5. Customer’s express courier account is acceptable

-6. Without courier account ,we will ship by DHL, FedEx, UPS or TNT

-7. Lead time would be up to the quantity, usually 2-5 work days

Note: This sample charge is for the first deal only and will be deducted in your future formal orders.

Brass copper phosphor bronze stamping part electrical contacts of socket switch