Полировальные булавки из нержавеющей стали магнитные инструменты для ювелирных изделий удаления заусенцев Вибрирующая отделочная

- Категория: Abrasives >>>

- Поставщик: Huzhou,Lucky,Bridge,Polishing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 643.94 $* | 675.20 $* |

| Aug-16-2025 | 637.71 $* | 669.17 $* |

| Jul-16-2025 | 535.76 $* | 562.76 $* |

| Jun-16-2025 | 626.15 $* | 657.37 $* |

| May-16-2025 | 545.57 $* | 572.98 $* |

| Apr-16-2025 | 616.19 $* | 647.0 $* |

| Mar-16-2025 | 610.75 $* | 641.15 $* |

| Feb-16-2025 | 605.27 $* | 635.54 $* |

| Jan-16-2025 | 599.25 $* | 629.91 $* |

Характеристики

Products Description

LUCKY BRIDGE MEDIA

The quality of any surface finish not only comes from the individual machine but from the correct selection of finishing medias and compounds. Lucky Bridge holds an extensive variety of plastic and ceramic, as well as porcelain and other high density polishing medias.

What We Provide

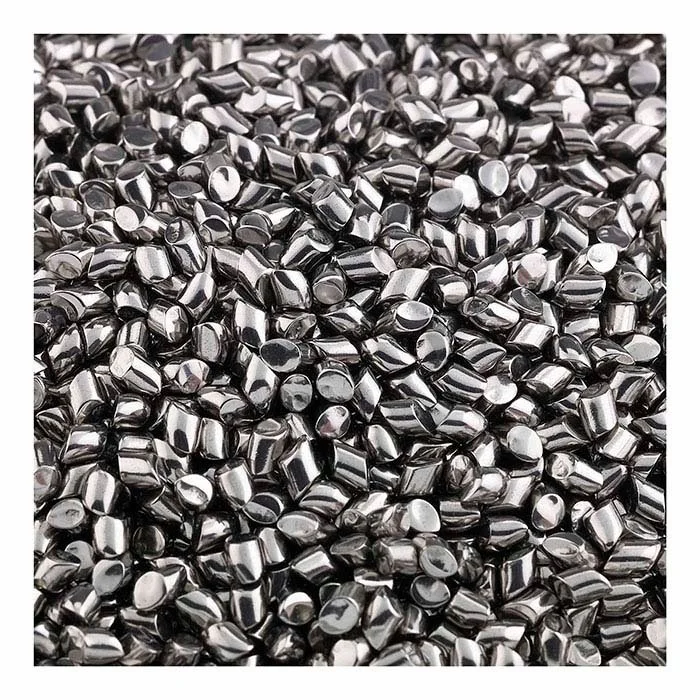

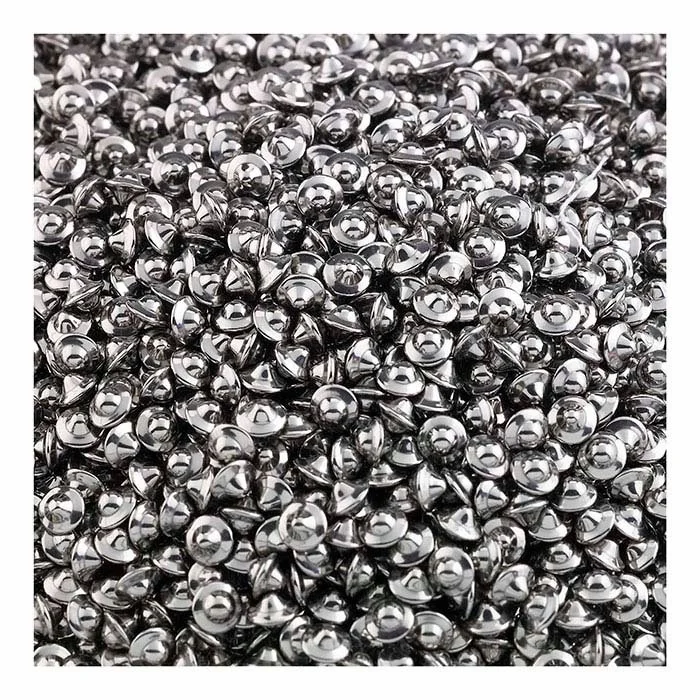

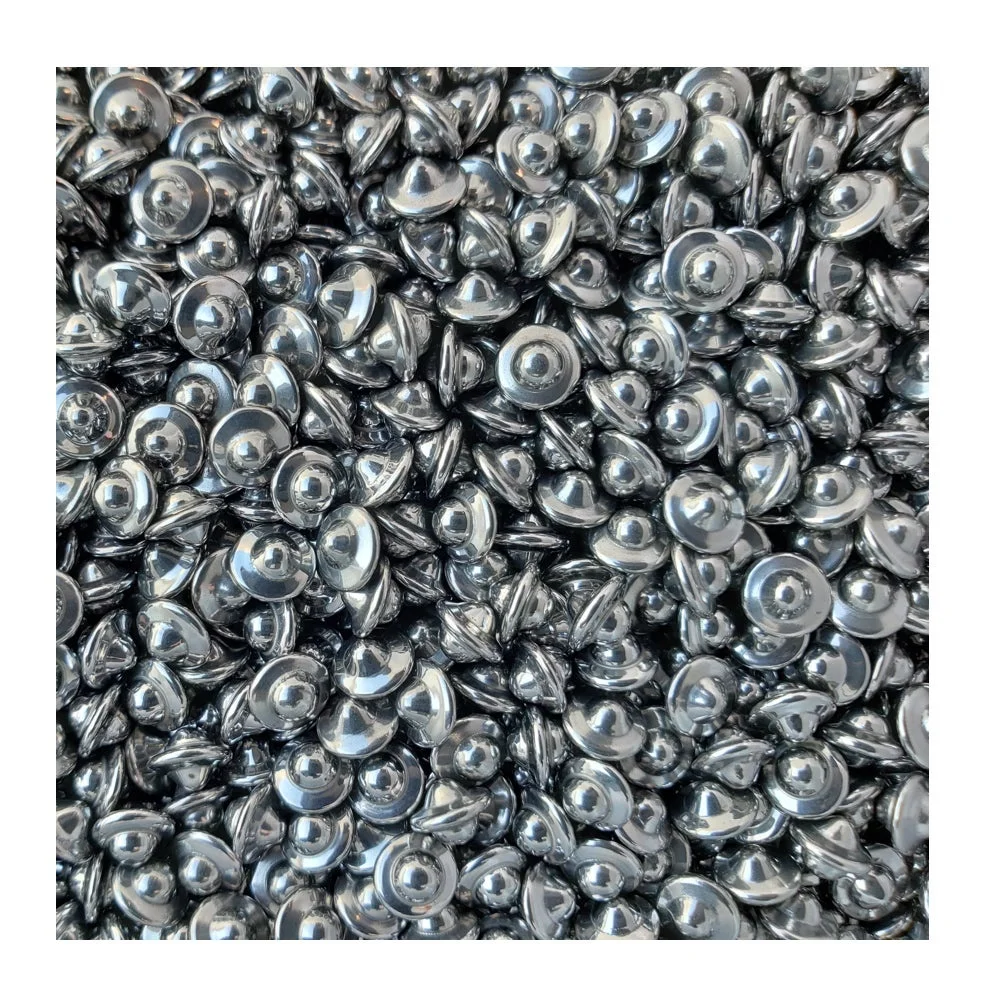

- Stainless Steel Burnishing Media

Simple, reliable stainless steel media needs no storage maintenance and requires only occasional cleaning. Use stronger compounds safely with this corrosion-resistant shot. The heavier weight of stainless steel burnishes uniformly on any metal surface.

304 Stainless steel burnishing media is rust and corrosion resistant and able to stand up to strong compounds. Using a Stainless steel media is important to avoid rust and works great for wet tumbling. The abrasion resistance of Stainless steel media is 3-5 times greater compared to cast steel media. Stainless steel media can be used over and over as long as it is stored properly.

Storing Tips:

After using, strain in a fine mesh Strainer and lay out the pieces on a dry towel.

Pat dry with another towel and let them air dry in a dry sunny area.

OR

Keep them stored completely submerged in water.

Either way they will provide you with many uses!

Simple, reliable stainless steel media needs no storage maintenance and requires only occasional cleaning. Use stronger compounds safely with this corrosion-resistant shot. The heavier weight of stainless steel burnishes uniformly on any metal surface.

304 Stainless steel burnishing media is rust and corrosion resistant and able to stand up to strong compounds. Using a Stainless steel media is important to avoid rust and works great for wet tumbling. The abrasion resistance of Stainless steel media is 3-5 times greater compared to cast steel media. Stainless steel media can be used over and over as long as it is stored properly.

Storing Tips:

After using, strain in a fine mesh Strainer and lay out the pieces on a dry towel.

Pat dry with another towel and let them air dry in a dry sunny area.

OR

Keep them stored completely submerged in water.

Either way they will provide you with many uses!

Technical Details

In most cases, we can meet your size requirements. Please contact us directly for sizes and prices. Or let us recommend similar sizes to you.

Before & After

Smoothing and Polishing Turbine Blades

Grinding and Smoothing Knife Blades

Removing The Oxidation Layer On Sliver Cutlery

Polishing Brass Cases

Grinding and Polishing Bone Plates and Implants

Derusting Workpiece

Related Tumbling Machines

Our Valued Clients

Our Clients Saying

Why Lucky Bridge

Huzhou Lucky Bridge Polishing Co., Ltd

Lucky Bridge provides a complete and perfect solution when solving product surface treatment problems for our customers. We make the most reasonable choices for finishing machine, finishing media and finishing compound based on the material performance, structural shape, size, surface state and final surface requirement of the products. Mass Polishing will meet the customer’s requirements for the surface treatment of different products and the technology provided can fully enable customers to obtain various processing effects.

Lucky Bridge Company has always been committed to providing customers with high-quality surface treatment products and advanced surface treatment processes. Over 25 years’ surface treatment experience in the area, we have the lowest cost and best technology to our customers. We are proud of our professional advice, quality machine, fast technical delivery, and trusted after- sales service.

Lucky Bridge Company has always been committed to providing customers with high-quality surface treatment products and advanced surface treatment processes. Over 25 years’ surface treatment experience in the area, we have the lowest cost and best technology to our customers. We are proud of our professional advice, quality machine, fast technical delivery, and trusted after- sales service.

FAQ

[Q1] How Do You Control the Quality of Mass Finishing Machines?

[A1] Laser Cutting → Welding → Shot Blasting → PU Casting → Painting → Testing. We use high-quality raw materials and control every production step strictly. After production, we will test all parts, especially the running of motor and PU quality. We promise that the machine has excellent performance. The warranty period of our machine is two years, in case of non-human damage.

[Q2] How Do You Control the Quality of Consumables?

[A2] Starting with the mixing ratio of raw materials, until the sorting of impurities. We have mastered the points that need attention in each step. The low loss, high grinding capacity and high polishing ability of media are our advantages.

[Q3] How Long is Your Lead Time?

[A3] We will arrange shipment within 12 days after payment. 15 days ready to leave at Shanghai port or Ningbo port.

[Q4] Can You Provide Sample Finishing Process?

[A4] Yes, we provide FREE sample finishing process. Mass Polishing does not charge any service fee for sample trial. Please contact us!

[Q5] Can You Provide Cleaning System?

[A5] Yes, we also make the cleaning system, it is also named waste water treatment.

[Q6] Can You OEM the Tumbling Media?

[A6] Yes, we offer OEM solutions for tumbling media. You just send us the media sample, we will make a testing report then we talk it.

[Q7] Can I Reduce the Noise of Vibratory Finishing Machine?

[A7] Yes, we can make a soundproof cover to reduce the noise.

[Q8] Is Easy to Operate Your Mass Finishing Machine?

[A8] Yes, the machine is very easy to operate, and we also guide you how to use at first time.

[Q9] What is Your Mass Finishing Machine Finishing Process Method?

[A9] Deburring, Polishing, Radiusing, Degreasing, Cleaning, Smoothing, Fine Polishing, Mirror Polishing, Super Finishing, Isotropic Finishing, Ball Burnishing, Derusting, Descaling, Pickling, etc.

[Q10] What is Your Packaging Way?

[A10] About machine, strong plywood for only one set. About media, 25kgs per woven bag, 1000kgs per pallet. About compound, 50kgs or 25kgs per plastic barrel.

[Q11] What are Your Price Terms?

[A11] FOB, CFR, CIF, EXW, DDU, DAP Price mainly. If you need delivered price (DDU, DAP), you may have to wait 1-2 days.

[Q12] What is the Nearest Port?

[A12] Shanghai port, Ningbo port.

[Q13] What is Your Payment Method?

[A13] T/T usually, we also accept Paypal. We provide all customers with Trade Assurance Order. “PQS” Protection. (Payment Protection, Quality Protection, Shipping Protection)

[Q14] Which Certificates do You Have?

[A14] ISO9001:2015, CE, SGS, Safe Transportation Report, etc.

[A1] Laser Cutting → Welding → Shot Blasting → PU Casting → Painting → Testing. We use high-quality raw materials and control every production step strictly. After production, we will test all parts, especially the running of motor and PU quality. We promise that the machine has excellent performance. The warranty period of our machine is two years, in case of non-human damage.

[Q2] How Do You Control the Quality of Consumables?

[A2] Starting with the mixing ratio of raw materials, until the sorting of impurities. We have mastered the points that need attention in each step. The low loss, high grinding capacity and high polishing ability of media are our advantages.

[Q3] How Long is Your Lead Time?

[A3] We will arrange shipment within 12 days after payment. 15 days ready to leave at Shanghai port or Ningbo port.

[Q4] Can You Provide Sample Finishing Process?

[A4] Yes, we provide FREE sample finishing process. Mass Polishing does not charge any service fee for sample trial. Please contact us!

[Q5] Can You Provide Cleaning System?

[A5] Yes, we also make the cleaning system, it is also named waste water treatment.

[Q6] Can You OEM the Tumbling Media?

[A6] Yes, we offer OEM solutions for tumbling media. You just send us the media sample, we will make a testing report then we talk it.

[Q7] Can I Reduce the Noise of Vibratory Finishing Machine?

[A7] Yes, we can make a soundproof cover to reduce the noise.

[Q8] Is Easy to Operate Your Mass Finishing Machine?

[A8] Yes, the machine is very easy to operate, and we also guide you how to use at first time.

[Q9] What is Your Mass Finishing Machine Finishing Process Method?

[A9] Deburring, Polishing, Radiusing, Degreasing, Cleaning, Smoothing, Fine Polishing, Mirror Polishing, Super Finishing, Isotropic Finishing, Ball Burnishing, Derusting, Descaling, Pickling, etc.

[Q10] What is Your Packaging Way?

[A10] About machine, strong plywood for only one set. About media, 25kgs per woven bag, 1000kgs per pallet. About compound, 50kgs or 25kgs per plastic barrel.

[Q11] What are Your Price Terms?

[A11] FOB, CFR, CIF, EXW, DDU, DAP Price mainly. If you need delivered price (DDU, DAP), you may have to wait 1-2 days.

[Q12] What is the Nearest Port?

[A12] Shanghai port, Ningbo port.

[Q13] What is Your Payment Method?

[A13] T/T usually, we also accept Paypal. We provide all customers with Trade Assurance Order. “PQS” Protection. (Payment Protection, Quality Protection, Shipping Protection)

[Q14] Which Certificates do You Have?

[A14] ISO9001:2015, CE, SGS, Safe Transportation Report, etc.