Высокопрочная одноволоконная полипропиленовая волоконная сетка для

- Категория: Fiber >>>

- Поставщик: Yueyang,Huaxing,Steel,Fiber,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 1.73 $* | 1.69 $* |

| Jul-15-2025 | 1.43 $* | 1.55 $* |

| Jun-15-2025 | 1.46 $* | 1.8 $* |

| May-15-2025 | 1.1 $* | 1.22 $* |

| Apr-15-2025 | 1.64 $* | 1.72 $* |

| Mar-15-2025 | 1.43 $* | 1.38 $* |

| Feb-15-2025 | 1.87 $* | 1.51 $* |

| Jan-15-2025 | 1.91 $* | 1.74 $* |

Характеристики

Product Description

Product Name | Polypropylene reticular fiber | ||||||

Material | 100% Modified PP | ||||||

Melting Point | 160 - 170°C | ||||||

Fiber Length | 12 18 20 Customizable | ||||||

Equivalent diameter(um) | 100-200 | ||||||

Tensile Strength | ≥400MPa | ||||||

Density(g/cm3) | 0.91 | ||||||

Density | 0.91+/-0.01 g/ cm³ | ||||||

Elongation At Break(%) | 15-30 | ||||||

Resistance to Acid,Alkali | Excellent | ||||||

Water absorption(%) | <2 | ||||||

Crack Elongation | ≥15% | ||||||

Products Description

The polypropylene mesh fiber is made of modified polypropylene as raw material and processed through processes such as extrusion, stretching, netting, surface modification treatment, and chopped cutting. The fibers are formed into a mesh shape. The Mesh fiber strengthens the bonding between the fibers and the concrete. A huge number of fibers are distributed in a three-dimensional state in the concrete, providing a net-like supporting effect, fundamentally changing the crack resistance, impact resistance, fatigue resistance, and abrasion resistance of the concrete, greatly improving the toughness and deformation ability of the concrete.The quality of the project has been significantly improved.

Applications

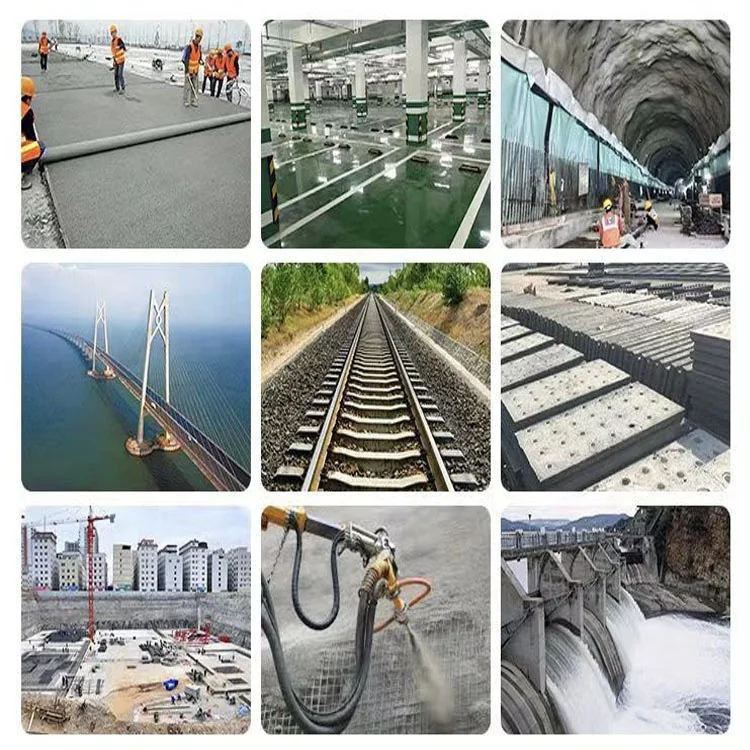

A). Projects like concrete road, bridge, airport road and factory floor which strictly require cracking resistance.

The life span of these projects will be lengthened for 5-10 years.

B). The walls of tunnels, mines, roofs and reservoir projects with special construction. When using spray technology in concrete construction, the polypropylene fiber added into the concrete can effectively decrease the spray concrete's deformation rate of the walls less than 8% and that of the roof less than 12%, and also can reduce the friction. It can improve the constructing efficiency and working environment and popularize the spray technology.

C). River courses and dams, etc. The polypropylene fiber can improve concrete's resistance to crack and squirt and wear to lengthen projects' life span.

D). Military defense works, dock banks and piers, etc. This fiber can greatly strengthen the concrete's spurt resistance and

heighten these projects' safety and lengthen their life span.

The life span of these projects will be lengthened for 5-10 years.

B). The walls of tunnels, mines, roofs and reservoir projects with special construction. When using spray technology in concrete construction, the polypropylene fiber added into the concrete can effectively decrease the spray concrete's deformation rate of the walls less than 8% and that of the roof less than 12%, and also can reduce the friction. It can improve the constructing efficiency and working environment and popularize the spray technology.

C). River courses and dams, etc. The polypropylene fiber can improve concrete's resistance to crack and squirt and wear to lengthen projects' life span.

D). Military defense works, dock banks and piers, etc. This fiber can greatly strengthen the concrete's spurt resistance and

heighten these projects' safety and lengthen their life span.

Typical physical properties:

Improve concrete crack resistance, impermeability, impact resistance, earthquake resistance, frost resistance, erosion resistance, burst resistance, aging resistance and workability, pumpability, and water retention.

1:Prevent the occurrence of concrete cracks

2:Improve the anti-permeability performance of concrete

3:Improve the freeze resistance and melt resistance of concrete

4:Improve the impact resistance, break resistance, fatigue resistance and antiknock performance of concrete

5:Improve the durability and aging resistance of concrete

6:Improve the fire resistance of concrete

1:Prevent the occurrence of concrete cracks

2:Improve the anti-permeability performance of concrete

3:Improve the freeze resistance and melt resistance of concrete

4:Improve the impact resistance, break resistance, fatigue resistance and antiknock performance of concrete

5:Improve the durability and aging resistance of concrete

6:Improve the fire resistance of concrete

Company Profile

Packing & Delivery

Packing

Packing 1: 1.0 per PE Film Bag, 10kg per plastic woven bag,6Ton/20'gp, 13Ton/40'HQ

Packing 2: 1.0 per water soluble Paper bag, 10kg/Carton,9.9Ton/40'HQ

Packing 3: other packing quantity can negotiate

Packing 2: 1.0 per water soluble Paper bag, 10kg/Carton,9.9Ton/40'HQ

Packing 3: other packing quantity can negotiate

Customer Feedback

Q1. How Can We Guarantee Quality?

A1: Always a Pre-Production Sample Before Mass Production;Always Final Inspection Before Shipment.

Q2: Are you trading company or manufacturer ?

A1: Always a Pre-Production Sample Before Mass Production;Always Final Inspection Before Shipment.

Q2: Are you trading company or manufacturer ?

A2: We are a professional manufacturing vendor in Yueyang city, Hunan Province, China.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge within 1kg but the cost of freight will be burden by custom.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge within 1kg but the cost of freight will be burden by custom.

Q4:Do you offer OEM or ODM service?

A4:Yes, OEM details can be discussed.

A4:Yes, OEM details can be discussed.