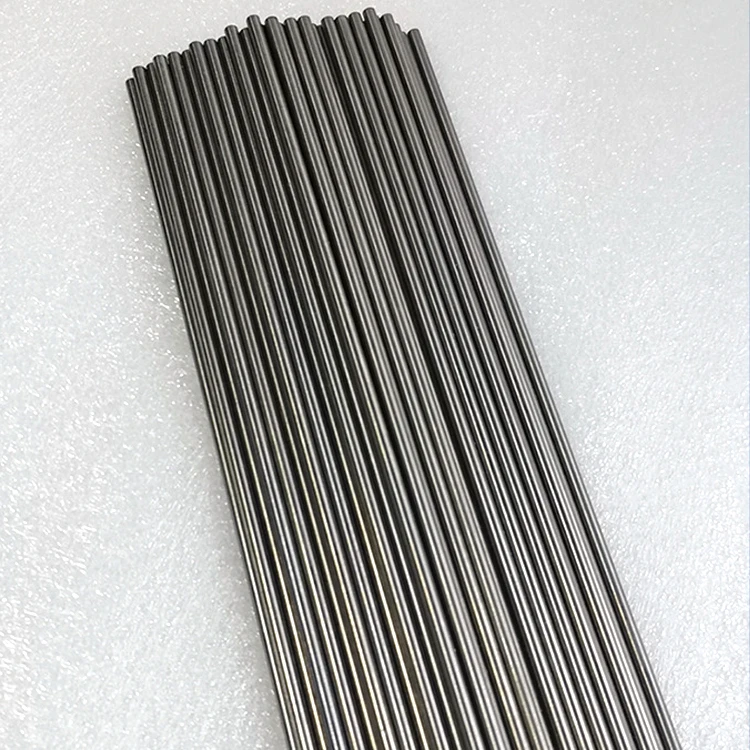

Китайский поставщик продажа чистый необработанный Тантал и сплав круглый стержень блок товары цена на металл за кг фунт

- Категория: Other Metals & Metal Products >>>

- Поставщик: Baoji,Dynamic,Trading,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.96 $* | 0.47 $* |

| Aug-16-2025 | 0.90 $* | 0.8 $* |

| Jul-16-2025 | 0.2 $* | 0.78 $* |

| Jun-16-2025 | 0.74 $* | 0.33 $* |

| May-16-2025 | 0.61 $* | 0.28 $* |

| Apr-16-2025 | 0.0 $* | 0.38 $* |

| Mar-16-2025 | 0.67 $* | 0.81 $* |

| Feb-16-2025 | 0.77 $* | 0.41 $* |

| Jan-16-2025 | 0.14 $* | 0.14 $* |

Характеристики

Product Overview

Item | pure raw tantalum and alloy round bar rod block products | ||||||

Material | 99.95% Pure Tantalum | ||||||

Size | customed | ||||||

MOQ | 1kg | ||||||

Grade | R05200, R05400, R05252, R05255, R05240 | ||||||

Tehnique | Forging ,Machining | ||||||

Application | Industrial,medical,aviation,military,salt-making,petrochemical,metallurgy,electronics ,chemical,etc ♦ electrical industry,Chemical, electronic, aerospace, aviation ♦ tool bit and aiguille ♦ modern medicine ♦ metallurgy, aviation | ||||||

Tantalum bar Mechanical Property

Tantalum Rods & Bar Mechanical Property | ||||||||

Products | Diameter/mm | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% | ||||

Tantalum | 3.0~18 | ≥175 | ≥140 | 25 | ||||

What are the properties of tantalum?

Pure tantalum has good plasticity, low deformation resistance, and low work hardening rate. Various profiles and special-shaped parts can be made by plastic processing methods.

Pure tantalum can be rolled into sheets, strips, foils, pipes and bars at room temperature, and the processing rate can reach more than 90%. To reduce oxidation, pure tantalum plastic working is often carried out at room temperature or below 500 °C.

Due to the high strength and poor plasticity of the ingot, the tantalum alloy must be billeted above 1200 °C, and the subsequent processing technology is the same as that of pure tantalum. The extrusion ratio of the billet should be greater than 4, and the forging ratio should be greater than 2. When the ingot is heated and opened, it is necessary to prevent gas pollution and reduce the plasticity of the material. In order to ensure that the product has good stamping and spinning properties, cross rolling is used. The processing rate before cross rolling should be kept around 80%.

The tantalum plate can be made into cups, caps, tubes, cones, nozzles and other parts of different shapes by spinning and deep drawing. The diameter of the swaging rod for wire drawing is generally 2.5 mm.

Because tantalum is soft and easy to bond with the mold and scratch the surface, the wire surface is often anodized to form an oxide film, and lubricated with beeswax.

Pure tantalum can be rolled into sheets, strips, foils, pipes and bars at room temperature, and the processing rate can reach more than 90%. To reduce oxidation, pure tantalum plastic working is often carried out at room temperature or below 500 °C.

Due to the high strength and poor plasticity of the ingot, the tantalum alloy must be billeted above 1200 °C, and the subsequent processing technology is the same as that of pure tantalum. The extrusion ratio of the billet should be greater than 4, and the forging ratio should be greater than 2. When the ingot is heated and opened, it is necessary to prevent gas pollution and reduce the plasticity of the material. In order to ensure that the product has good stamping and spinning properties, cross rolling is used. The processing rate before cross rolling should be kept around 80%.

The tantalum plate can be made into cups, caps, tubes, cones, nozzles and other parts of different shapes by spinning and deep drawing. The diameter of the swaging rod for wire drawing is generally 2.5 mm.

Because tantalum is soft and easy to bond with the mold and scratch the surface, the wire surface is often anodized to form an oxide film, and lubricated with beeswax.

Product packaging

SIMILAR PRODUCTS

Company Profile

Certifications

Exhibition photos

Production Process

FAQ

1.Are you a factory or trading company?

Our factory has 10 years experience in production.

2.Are you able to provide samples? MOQ?

Yes, we can supply you free sample. MOQ:1kg.

3.Do you accept customed?

Yes, we can according to your unit weight or drawings processing.

4.Do you inspect the finishing products?

Yes, each product will be inspected by our QC before shipping.

5.What is the shipping cost?

It mainly depends on weight, volume, packing size and destination port.

6.What's your delivery time?

In stock, 1-2 days, if not, according to your quantity.

Our factory has 10 years experience in production.

2.Are you able to provide samples? MOQ?

Yes, we can supply you free sample. MOQ:1kg.

3.Do you accept customed?

Yes, we can according to your unit weight or drawings processing.

4.Do you inspect the finishing products?

Yes, each product will be inspected by our QC before shipping.

5.What is the shipping cost?

It mainly depends on weight, volume, packing size and destination port.

6.What's your delivery time?

In stock, 1-2 days, if not, according to your quantity.

Похожие товары

Ru-Ir покрытие смешанный оксид металла титановая сетка анод

US $30.00-$50.00

Платиновый плинизированный титановый анод для электролиза

US $1.50-$2.00

Вольфрамовый стержень цилиндра (W)-85% и медь (CU)-15% сплав

US $43.45-$82.12

Стержни из ниобиевого сплава C103, цена от китайского производителя

US $80.00-$150.00