Проектирование прошивки от производителя проектирование

- Категория: Other Telecommunications Products >>>

- Поставщик: Microcyber,Corporation

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.42 $* | 0.98 $* |

| Aug-19-2025 | 0.59 $* | 0.22 $* |

| Jul-19-2025 | 0.34 $* | 0.66 $* |

| Jun-19-2025 | 0.70 $* | 0.87 $* |

| May-19-2025 | 0.44 $* | 0.66 $* |

| Apr-19-2025 | 0.28 $* | 0.68 $* |

| Mar-19-2025 | 0.76 $* | 0.59 $* |

| Feb-19-2025 | 0.18 $* | 0.85 $* |

| Jan-19-2025 | 0.71 $* | 0.83 $* |

Характеристики

Original Equipment Manufacturer

Product Description

What do you need for OEM Services

Develop custom communication card components for customers, including software and hardware

Develop customized DD files for customers

Provide related testing services for customers, including physical layer testing, protocol stack testing, interoperability

testing, etc

Assist customers to complete the equipment certification test

Develop customized DD files for customers

Provide related testing services for customers, including physical layer testing, protocol stack testing, interoperability

testing, etc

Assist customers to complete the equipment certification test

Service | Protocol |

Development Toolkit | FF H1 |

Development Toolkit | PROFIBUS PA |

Development Toolkit | HART |

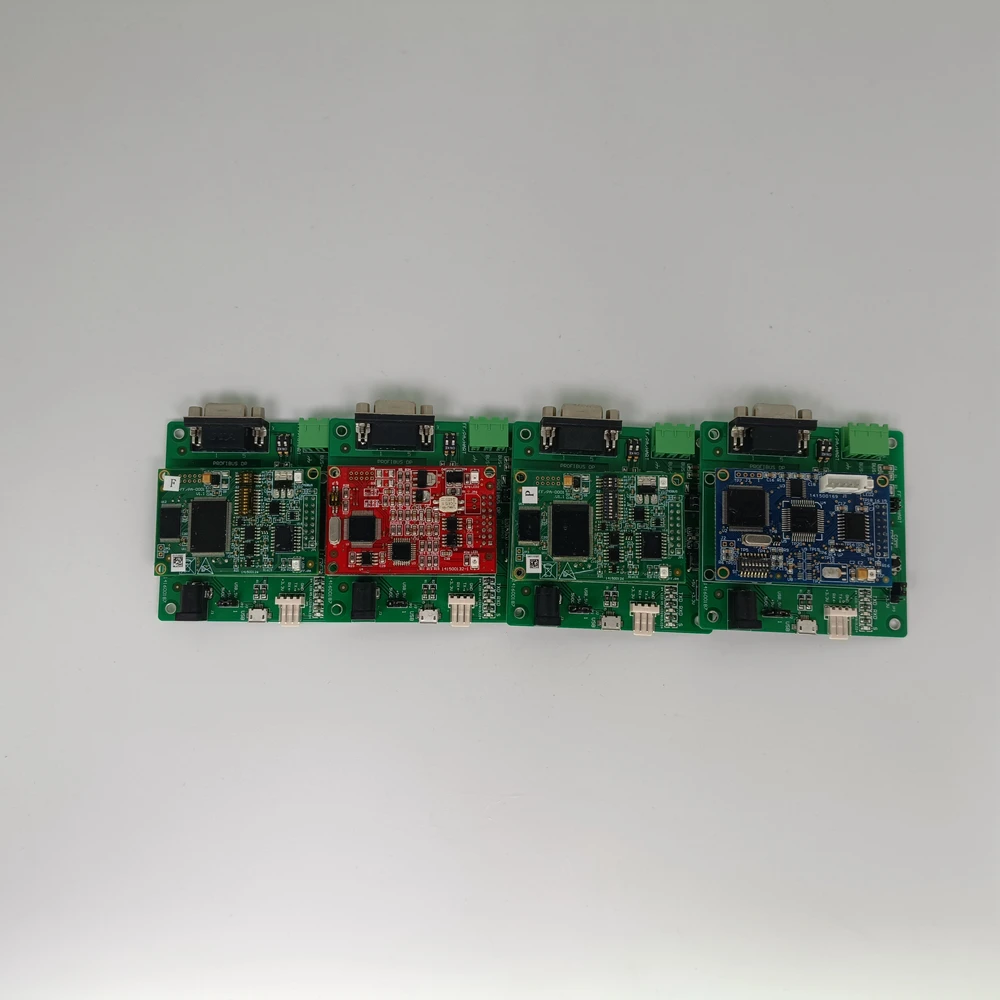

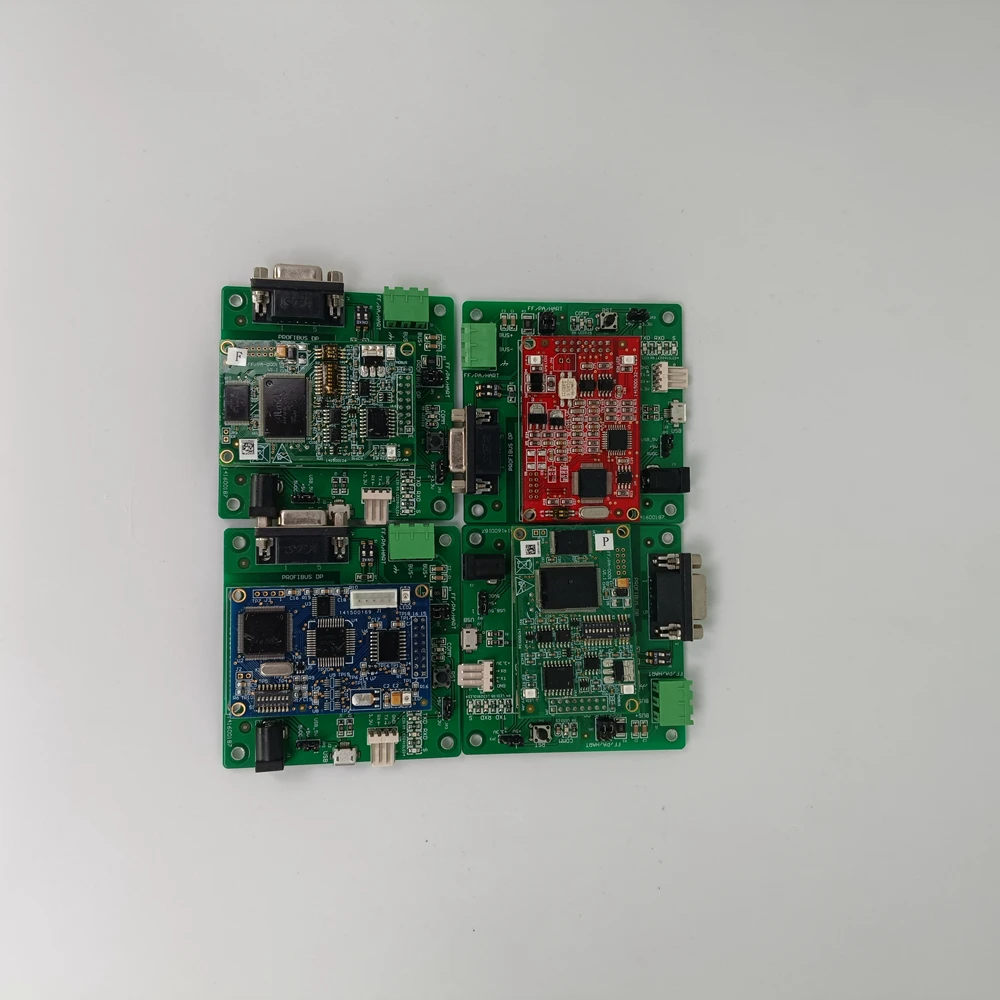

FIELDBUS Development Toolkit

Product information

Hardware:

EMC certification and intrinsic safety certification

FF physical layer conformance test Flash ≥256K

Support Atmel ARM7 series CPUDiscrete MAU

RAM ≥128K

Support asynchrony serial interface,baud rate is changeable

Support stable data memory Support common I/O port

Power supplier: 9 ~ 32 VDC

Support the communication controller -- Microcyber FBC0409

Current consumption: ≤ 15mA Supply to customer HW: 3V, 10mA or 5V, 6mA

Software:

FF technical data:

Support Multi2000 compiler Support operating system transplantation --- Nucleus PLUS is used

Link Master function

Communication stack—FF conformance test Function block—FF interoperability test

Standard FMS and SM service

Transducer block

Standard function block interface

Standard function block and advanced function blockFlexible function block

DD source file, CFF file and function block source file

Profibus PA technical data:

GSD file and function block source file

DP slave functionCompatible with DP、DPV and DPV2

Application layer interface

Standard function block interface

GSD file and function block source file

Development Procedure of Fieldbus Device

The tool kit provides:

Hardware schematic diagram,PCB diagram

Device capacity file(CFF)description(only for FF H1)

Source code for device description ( DDL language,only for FF H1)

EDDL/GSD file(text file,only for Profibus PA)

Function block source code(C language)

Communication stack library(FF H1or Profibus PA)

Library file

Header

User interface function

Interface library for function block

Library file

Header

User interface function

Operating system interface

Source code for driving communication controller(C language)

User needs to have:

ARM integration development tool

FF Tokenizer DD development tool(including standard DD library and compiler) V2..0 upwards(only for FF H1)

ARM emluator

Testing and debugging environment: Profibus system, FF system

Development explanation

The tool kit provides:

Hardware schematic diagram,PCB diagram

Device capacity file(CFF)description(only for FF H1)

Source code for device description ( DDL language,only for FF H1)

EDDL/GSD file(text file,only for Profibus PA)

Function block source code(C language)

Communication stack library(FF H1or Profibus PA)

Library file

Header

User interface function

Interface library for function block

Library file

Header

User interface function

Operating system interface

Source code for driving communication controller(C language)

User needs to have:

ARM integration development tool

FF Tokenizer DD development tool(including standard DD library and compiler) V2..0 upwards(only for FF H1)

ARM emluator

Testing and debugging environment: Profibus system, FF system

Development Procedure

Useful documents include user manual of development tool kit and related documents of developing device.

Program transducer blocks according to requirements, and add output parameter and calibration etc. Development tool kit includes all standard function blocks and most of advanced function blocks. If there are no special requirements, the function blocks do not need to be developed. The parameters of communication stack have default initial value, the parameters of communication stack do not need to be revised. If user has special requirements, some parameters can be revised by using configuration software, such as device address, device data link layer parameter and device timer parameter.

Development tool kit use Nucleus operating system. If user uses different operating system, operating system porting needs to be done.

Developing device description with FF H1: CFF file(text file)and DD file(using DDL language need to be programmed); DD file can be used after translating and edit.

Developing device description with Profibus PA: GSD and EDDL file(text file).

HART Development Toolkit

Components of HART Development Toolkit

HART Development toolkit consists of communication board hardware, software development toolkit and related technical documents.

Characteristic of communication board hardware:

4 ~ 20mA output with digital communication of HART protocol (two-wire)

Comply with HART protocol communication characteristicPassed IECEx explosionproof certification

Configuration debugging software remote management via handheld or PCPassed EMC testing certification

Interface board communication: serial port and I/O, four I/Os at most

Support CPU failure alarm, write protection jumperHigh limit alarm current: >=20.8mA

Low limit alarm current: >=3.9mA

Communication board development toolkit includes:

Parts connected with sensor: light coupling isolationSource program example file: mainly consists of template file for user to develop function blocks, based on this file, the user can omplete developing a function block in a short time.

Library file: mainly consists of HART-STACK application program interface library and HART-STACK protocol library. HART-STACK library will pack protocol stack function, which providing customers with function interface accessing protocol stack, without knowing the protocol stack communication technology.

The user is requested to purchase:

IAR Embedded Workbench for MSP430 development environment. HART communication board development toolkit software development uses IAR Embedded Workbench for MSP430 integrated development toolkit from IAR System, the version is 4.11B.

DD-IDE: In order to write device description file, the user is requested to purchase DD-IDE integrated development environment.

Course of HART Communication Board

Development

1.Preparation

The user is planning to purchase: consists of integrated development environment and DD complier. The user may join foundation to become a member, so that to get a membership price when purchase products in foundation.

2. Design Period

The development staff shall read HART development toolkit and related documentations, and know hardware interface and software application program interface. The development staff should have knowledge of Foundation fieldbus and be good at C programming.

According to development technical documents, the user shall design the software and confirm the standard function block, and as well as own customized function blocks and transducer block, etc., and make sure of the communication interface and protocol between communication board and other device.

3. Development Period

The user shall use the template file provided by development toolkit to develop customized function blocks and transducer blocks, and fill in application program initialization function, transfer HART-STACK application program interface initialization program, register function block info to HART-STACK library, and register transducer block running task. The user may refer to “HART-STACK application program interface manual” for more info about HART-STACK library. The user may need the communication between communication board and other device, which can be carried out via serial port drive program provided by communication board. Finally the user needs connect program to get target code, and burn in the target code to communication board via H-JTAG. For the info exchange with control system, the user needs to write DD file for own developed device. Please refer to the examples provided by development toolkit.

4. Testing Period

After completing software development, the device is ready for testing. First it is the simple function testing, the user can select configuration software (e.g. HART Server).and then test the user function block functions via the online function testing via software. Also, the certification test is needed, such foundation testing. It requires the customers to be the foundation member and purchase testing environment. Please refer to “Development guidance for HART communication board”.

PROFIBUS-PA Development Toolkit

Components of PROFIBUS-PA Development Toolkit

PROFIBUS-PA Round Card Development Toolkits consists of round card hardware, software toolkit and technical documents.

Hardware characteristic:

Same hardware structure, different firmware to realize PROFIBUS PA or FF H1device

Passed EMC Test Certification: complied with IEC 61326-1:1997Bus power supply: 9~32 VDC

Passed NEPSI FISCO Essence Safety Certification: Ex ia IIC T4/T6Current consume: ≤ 14mA

Complied with IEC61158-2 physical layer standard, passed physical layer certification test

Flexible to communicate with user’s board cards, supporting asynchronous serial ports and universal I/O portsSupport crystal display and magnetic stick local operation

Round card size: Φ65mm

Working temperature: -40℃~85℃ 6mA/3.3V stable power supply(or customized order) for user’s board cardsUser’s board cards communication ports: USART serial ports

User’s board cards isolation

PA Development Toolkits including:

Source codes: mainly consists of function block source file and example file of user application program, with which user can complete development of function block and other application program in short time.

PAShell library: PAShell library packages function of PROFIBUS DP Slave protocol stack, providing interface access protocol stack for user, it is unnecessary for user to understand the communication technology of protocol stack in detail.

Source code of driver program: mainly consists of USART driver program and LCD display driver program. Device Description sample file: DD and CFF sample files are provided by PA development toolkits. User is able to develop his own device description file according to these sample files and to realize integration between device and control system.

These tools are needed to buy by developer:

Nucleus operation system. It is needed to use Nucleus operation system, which should be bought by user.

Green Hills Multi development environment. Multi integration development tool of Green Hills Inc, Version 3.6 and above is used.

PA Round Card Development process

1. Preparation Phase

Buy the necessary software tools such as NUCLEUS operation system and MULTI integration development environment.

2. Design Phase

You should read relative documents about PROFIBUS-PA development tools and get to be familiar with hardware interface and software application program. Developers need to have knowledge of PROFIBUS DP slave communication specification, and PROFIFBUS PA profile, and good program ability for C Language.

The user should do software design according to the technical development document and make it clear that what type of blocks are used in your device, then design physical access channel for these blocks. Furthermore, you should specify the communication protocol between your peripheral device and PA round card.

3. Development Phase

You should develop function block and transducer block program reference to function blocks source program provided by development tools, and register information of function blocks into PAShell base. The information about FBShell base is reference to “PROFIBUS-PA Application Program Interface Brochure”. Users can realize communication between round cards and peripheral device by serial ports driver provided by round cards. Finally, you should debug connecting program to get target code, use H-JTAG software to brun target codes to round cards. It is needed for user to write GSDdocument and EDD document to exchange information with control system. The detailed content can be referenced to the examples of development toolkits.

4. Test Phase

After software development, you can test your device. First, the simple function test can be divided into DP slave communication test and PA function block test. SIMATIC STEP7 software can be used in DP slave communication test, which is to test whether configuration between DP slave communication and GSD document is right. SIMATIC PDM device management software is used in PA function block test, which is to test whether parameter description of PA function block is right, the execution of function block is right, and whether EDD file is satisfied the requirements, etc. Furthermore, users are required to have more professional test such as interoperability test. The detailed test steps can be referenced to “PROFIBUS-PA Application Program Interface Manual”.

Company Profile

Certification

Microcyber is the member of FCG (FieldComm Group) and the Profibus National Organization (PNO).

Microcyber has ISO 9001 certification.

As a Development Services Provider, Microcyber provides extraordinary services and solutions of Foundation Fieldbus technology.

Many of our products have passed FF certification, PA certification, HART certification, and NEPSI explosion-proof certification, etc.

Microcyber is the member of FCG (FieldComm Group) and the Profibus National Organization (PNO).

Microcyber has ISO 9001 certification.

As a Development Services Provider, Microcyber provides extraordinary services and solutions of Foundation Fieldbus technology.

Many of our products have passed FF certification, PA certification, HART certification, and NEPSI explosion-proof certification, etc.

Workshop

Microcyber’s production center is 1700m2, with anti-static ground, ventilating system, air source transporting system, temperature and humility control system and production devices.

The production center consists of 4 workshops and 1 professional lab, they are: production workshop, assembly workshop, ageing workshop, maintenance workshop and product lab.

There are professional production line, pressure transmitter assembly line, instrument assembly line, control system module assembly line and product testing line.

Microcyber has the batch capacity for 10 thousand devices per year.

Microcyber’s production center is 1700m2, with anti-static ground, ventilating system, air source transporting system, temperature and humility control system and production devices.

The production center consists of 4 workshops and 1 professional lab, they are: production workshop, assembly workshop, ageing workshop, maintenance workshop and product lab.

There are professional production line, pressure transmitter assembly line, instrument assembly line, control system module assembly line and product testing line.

Microcyber has the batch capacity for 10 thousand devices per year.

Exhibition

Microcyber has participated in many significant international exhibitions, such as ISA, Automation World, CIIF, Hannover Method, Automation Expo and MICONEX.

Microcyber will keep moving on and hope to meet you in the near future.

Microcyber has participated in many significant international exhibitions, such as ISA, Automation World, CIIF, Hannover Method, Automation Expo and MICONEX.

Microcyber will keep moving on and hope to meet you in the near future.

FAQ

Q: Can I get a free electronic manual?

A: Yes, if you want it, please contact us.

Q: Can you provided OEM service?

A: Yes, we can, such as communication board, we can also provided fieldbus development toolkit.

A: Yes, if you want it, please contact us.

Q: Can you provided OEM service?

A: Yes, we can, such as communication board, we can also provided fieldbus development toolkit.

Похожие товары

Промышленный RS-232 в RS-422 конвертер с терминальным блоком

US $3.00-$5.00

Конвертер RS232 в RS485

US $3.00

Металлическая лондонская красная телефонная будка

US $500.00-$1500

Huawei ASPB 64 порта VoIP плата интерфейса абонента для MA5616

US $450.00-$500.00