Автоматическая профессиональная стальная машина для производства

- Категория: Metal & Metallurgy Machinery >>>

- Поставщик: SSS,Hardware,International,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 22015.5 $* | 23116.15 $* |

| Aug-19-2025 | 21830.81 $* | 22922.34 $* |

| Jul-19-2025 | 18315.22 $* | 19231.75 $* |

| Jun-19-2025 | 21460.45 $* | 22533.38 $* |

| May-19-2025 | 18685.11 $* | 19619.77 $* |

| Apr-19-2025 | 21090.86 $* | 22145.92 $* |

| Mar-19-2025 | 20905.4 $* | 21950.7 $* |

| Feb-19-2025 | 20720.33 $* | 21756.17 $* |

| Jan-19-2025 | 20535.91 $* | 21562.89 $* |

Характеристики

Product Overview

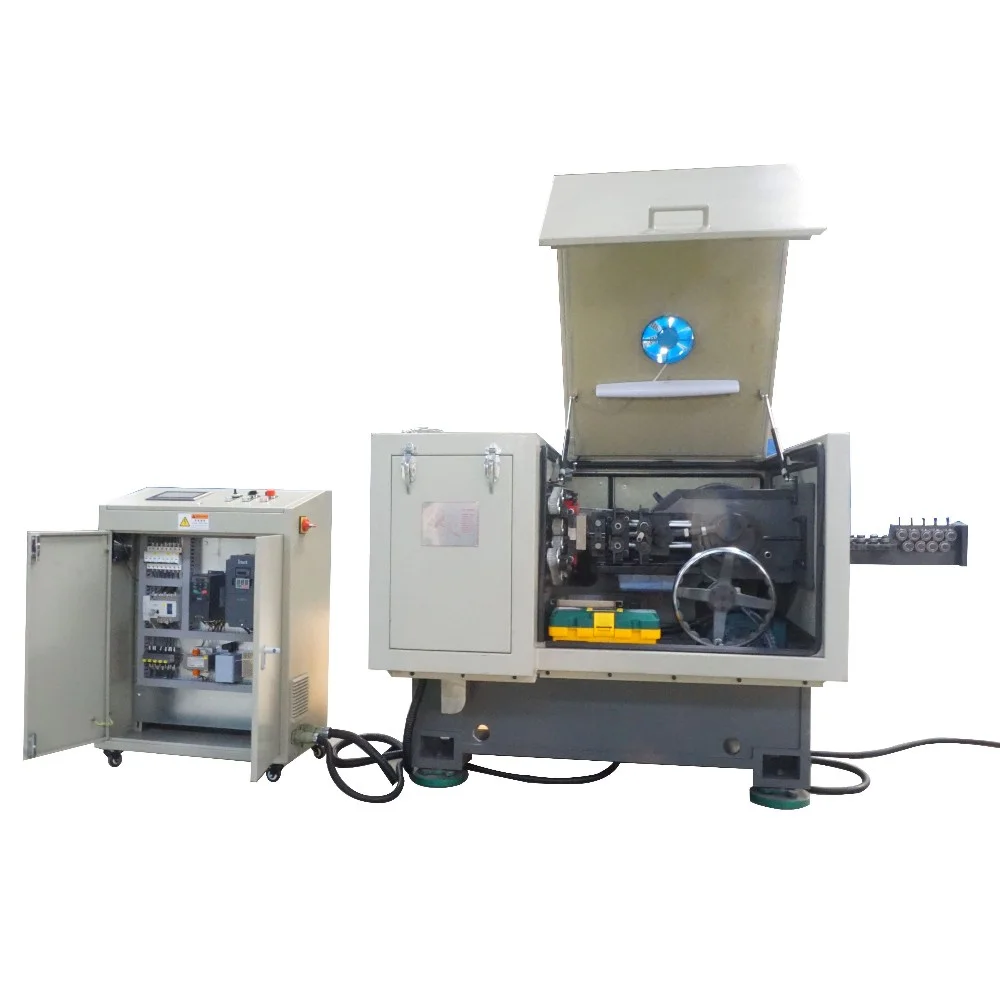

High-speed Nail Making Machine

This machine is a high-speed and energy-saving nail making equipment, mainly used to produce and process high-quality ordinary round head nails and D-shape clipped head nails with consistent shank length and head diameter for final products coil nails, plastic strip nails and paper strip nails.

Machine Advantages

1.Long service life,no less than the traditional common nail making machine, for at least seven years.White belt at low cost and long life which is 5-6 months without an incorrect operation.

2.Automatic oiling , few lubrication points,much less than traditional machines and other nail making machines on market.It is still very tidy when operating.

3.High Production. Set specification 2550 as an example,about 900 kg / 8 hours.

4.No dismantle if not change nail mold specifications which can work for 3 months. Nail cutter 60 classes (8 hours / day, 2.5 wire diameter). Punch time is five times than ordinary equipment depending on the actual using status.

5.Nail cutter do cutting without touch, shear number can reach at least 800 million times (8,000,000 is the cutting times of wire diameter 2.0mm, rough wire diameter will multiplied);low consumption of nail mold, no crack, no fixed mold raw wear, no mold clogging, a single pair of nail mold can cut at least 50 million times, punching is more than 25 million times. Nail cutter, nail mold, punch can be repaired for many times at the same cost compared with general equipment.

5.Nail cutter do cutting without touch, shear number can reach at least 800 million times (8,000,000 is the cutting times of wire diameter 2.0mm, rough wire diameter will multiplied);low consumption of nail mold, no crack, no fixed mold raw wear, no mold clogging, a single pair of nail mold can cut at least 50 million times, punching is more than 25 million times. Nail cutter, nail mold, punch can be repaired for many times at the same cost compared with general equipment.

6.Super energy-saving: actual consumption of High- speed nail making machine is about 3.5KW,1 ton nail output can save electricity about 20 degrees; while 2.5 sets of ordinary nail making machine consumption is 5-6KW due to long slide stroke and multi sliding friction parts

7.60% labor saving because of its high efficiency. Coiling nails efficiency gains at least 50% with a high-frequency welding machine as each nail is quality product without stuck and stop, even if in the speed of 1900 nails/min, coiling speed can improve 30%, so that can reduce 40% labor cost.

8.Seven alarming sensors can protect the machine and ensure the nail quality very well.

PRODUCT SPECIFICATIONS

Machine Model | Nail Length (mm) | Nail Dia. (mm) | Capacity (pcs/min) | Weight (kg) | Dimension (mm) |

SSS-ZDJ-X50 | 25-60 | 1.8-2.8 | 760 | 2500 | 1500*950*1300 |

SSS-ZDJ-X90 | 32-90 | 2.0-3.5 | 760 | 2800 | 1900*1200*1150 |

SSS-ZDJ-X130 | 70-130 | 2.5-4.5 | 600-800 | 3388 | 2200*1300*1300 |

SSS-ZDJ-X150 | 70-150 | 2.5-5.0 | 700(500-600pcs/per min for length more than 100mm) | 4200 | 2400*1400*1400 |

Nail cutter holder adopts pendulum structure

1. shorter stroke and lower mechanical wear

2. High precision, nail cutters work without touch with longer service life.

3. One set of cutters’ cutting times up to 10 million times

2. High precision, nail cutters work without touch with longer service life.

3. One set of cutters’ cutting times up to 10 million times

Unique patent, two-time heading, double-dies and double-punches structure

1. Bigger nail heads can be easily gotten

2. Nail heads are always very round and in the center.

3. Nail head without knock marks, consistent and good looking

4. Uniform thickness of the nail cap diameter.

5. Hollow design gripping dies, no small head, no ash blocking

2. Nail heads are always very round and in the center.

3. Nail head without knock marks, consistent and good looking

4. Uniform thickness of the nail cap diameter.

5. Hollow design gripping dies, no small head, no ash blocking

Wire feeding and anti-backing structure

1. High-precision feeding unit. Length difference can be controlled within 0.3mm

2. With unique wire feeding and anti-backing structure, the nail scraps can be completely separated from the nail shank to ensure nail quality.

2. With unique wire feeding and anti-backing structure, the nail scraps can be completely separated from the nail shank to ensure nail quality.

Machine Working Process

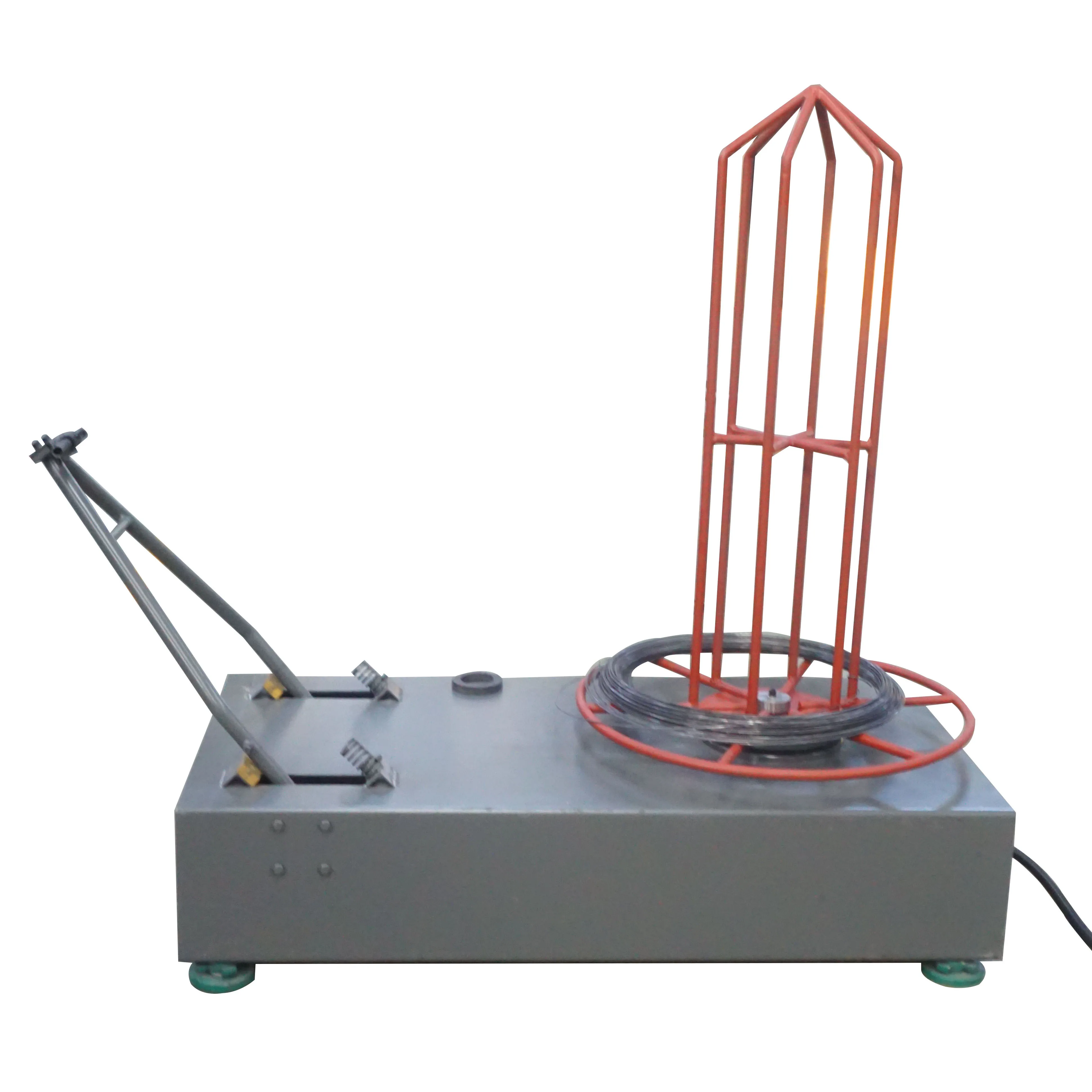

1. Wire Material

2. Wire Straightening

The adjustment frame is mainly for straightening the wire to facilitate the wire feeding and cutting in the next step.

3. Wire Feeding

The infeeding clip is mainly used for stable wirefeeding.

The outfeeding clip can stabilize the length of the wire feeding, ensuring that the length of the nail is consistent; the wire diameter will be the same as the diameter of the clips.

The outfeeding clip can stabilize the length of the wire feeding, ensuring that the length of the nail is consistent; the wire diameter will be the same as the diameter of the clips.

4. Nail Cutting

Forming a nail cap by impact.

5. Nail Heading

6. Quality Checking

Favorable comment

Packing and Shipping

1. Shipping port: Shanghai

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

2. Validity: within 30 days

3. Payment terms: 30% T/T down payment in advance and 70% before shipment

4. Warranty: 1 year from date of installation

5. Installation/Operation/Service/Maintenance Manual: Provided In English

6. In wooden pallet, In plastic film, the spare parts and cabinet packed by wooden box.

Successful Project

Middle East guest

America guest

Asian guest

Our Exhibition

Cable & Wire Fair-India

Hardware and Hand Tools-Vietnam

Canton Fair-Guangzhou

Our Company

SSS HARDWARE INDUSTRY CO., LTD. specializes in nail making machines, high speed nail making machines, coil nail welding machines, nail polishing machines, thread rolling machines, wire drawing machines, staple making machines, as well as the production lines,all kinds of nails and welding wires.

Our factory covers an area of 60,000 square meters and owns 300 sets of equipment. We are supported by seven branch work plants to ensure our good quality and prompt delivery. Quality is our priority and your satisfaction is what we are striving for.

Our products are very popular in UK , Italy, Germany, France, Poland, Slovenia, Bulgaria, Belarus, Serbia, Russia, Canada, America, Mexico, Korea, Brazil, Argentina, Colombia, Guatemala, Venezuela, South Africa & New Zealand. You can totally rest assured of our guaranteed quality and our good after-sales service. Please feel free to contact us for more details including prices.

Looking forward to cooperating with you soon based on our all-time guaranteed quality, best price and service !

Our factory covers an area of 60,000 square meters and owns 300 sets of equipment. We are supported by seven branch work plants to ensure our good quality and prompt delivery. Quality is our priority and your satisfaction is what we are striving for.

Our products are very popular in UK , Italy, Germany, France, Poland, Slovenia, Bulgaria, Belarus, Serbia, Russia, Canada, America, Mexico, Korea, Brazil, Argentina, Colombia, Guatemala, Venezuela, South Africa & New Zealand. You can totally rest assured of our guaranteed quality and our good after-sales service. Please feel free to contact us for more details including prices.

Looking forward to cooperating with you soon based on our all-time guaranteed quality, best price and service !

Workshop

Factory Overview

Assembly Shop

Finished Product Workshop

FAQ

1. Who are we?

We are based in Anhui, China, start from 2007, sell to Southeast Asia, Mid East, Eastern Europe, South America, Africa, South Asia, North America, Central America, Southern Europe. There are total about 11-50 people in our office.

2. How can we guarantee quality ?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us ?

All kinds of nails, high speed nail making machine, wire collating machine, nail polishing machine, thread rolling machine, wire drawing machine, and staple making machines.

4. Why should you buy from us not from other suppliers ?

Competitive price, Excellent quality, Prompt delivery, Good service

5. What services can we provide ?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery;

Accepted Payment Currency: USD, EUR, CAD, AUD, HKD, GBP, CNY;

Accepted Payment Type: T/T, L/C, D/P, D/A, Money Gram, Credit Card, PayPal, Western Union;

Language Spoken: English, Chinese, Korean, Russian

We are based in Anhui, China, start from 2007, sell to Southeast Asia, Mid East, Eastern Europe, South America, Africa, South Asia, North America, Central America, Southern Europe. There are total about 11-50 people in our office.

2. How can we guarantee quality ?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us ?

All kinds of nails, high speed nail making machine, wire collating machine, nail polishing machine, thread rolling machine, wire drawing machine, and staple making machines.

4. Why should you buy from us not from other suppliers ?

Competitive price, Excellent quality, Prompt delivery, Good service

5. What services can we provide ?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery;

Accepted Payment Currency: USD, EUR, CAD, AUD, HKD, GBP, CNY;

Accepted Payment Type: T/T, L/C, D/P, D/A, Money Gram, Credit Card, PayPal, Western Union;

Language Spoken: English, Chinese, Korean, Russian

Contact US