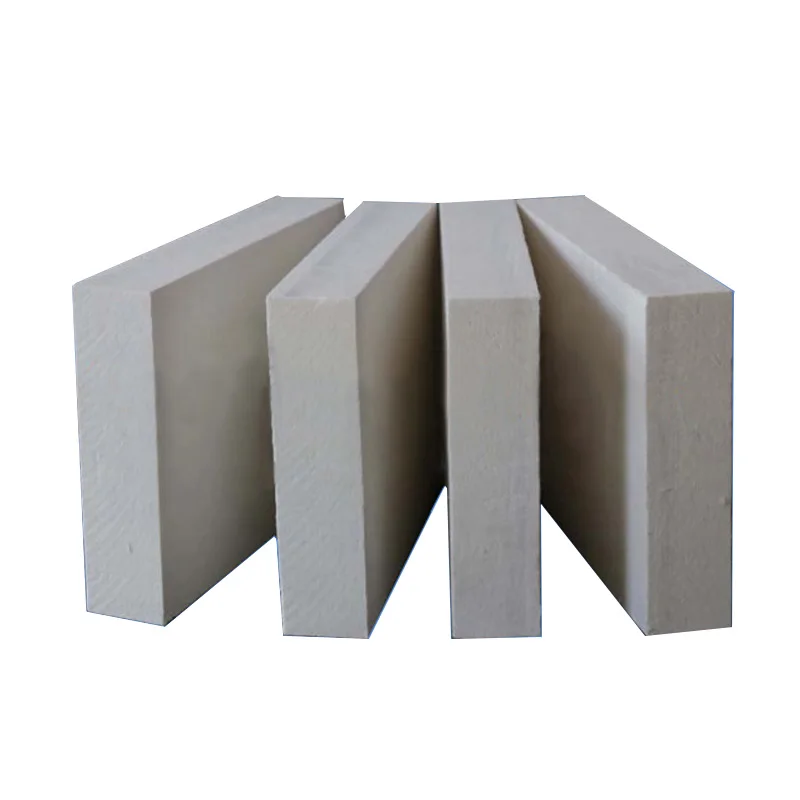

Алюминиевая керамическая плита

- Категория: Ceramic Fiber Boards >>>

- Поставщик: Zhengzhou,Shibo,Nonferrous,Metals,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.81 $* | 0.41 $* |

| Aug-19-2025 | 0.96 $* | 0.5 $* |

| Jul-19-2025 | 0.48 $* | 0.18 $* |

| Jun-19-2025 | 0.58 $* | 0.41 $* |

| May-19-2025 | 0.81 $* | 0.54 $* |

| Apr-19-2025 | 0.61 $* | 0.28 $* |

| Mar-19-2025 | 0.5 $* | 0.41 $* |

| Feb-19-2025 | 0.31 $* | 0.83 $* |

| Jan-19-2025 | 0.56 $* | 0.36 $* |

Характеристики

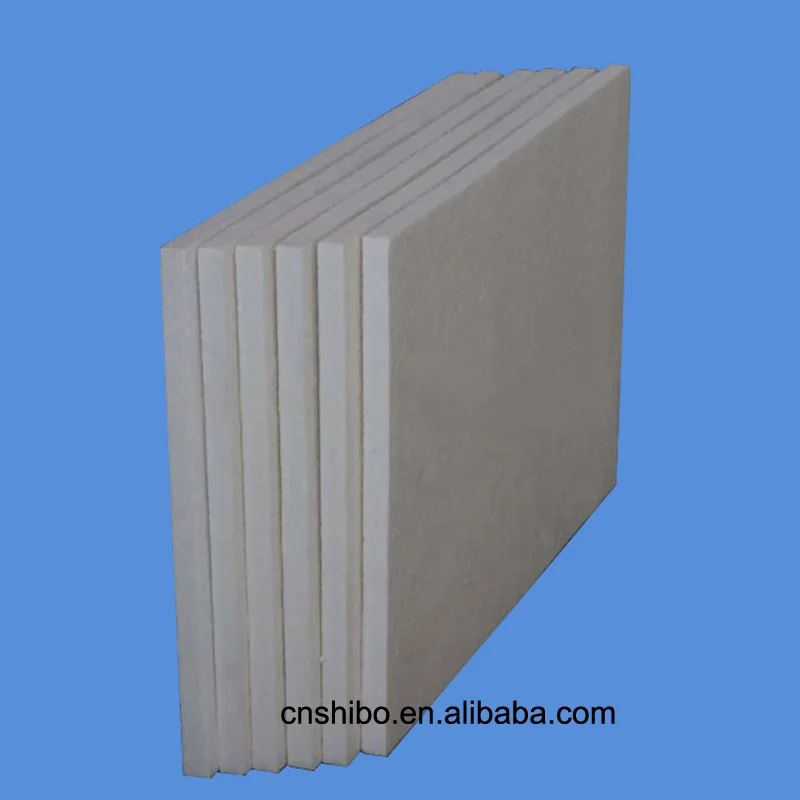

Alumina ceramic fiber board for furnace

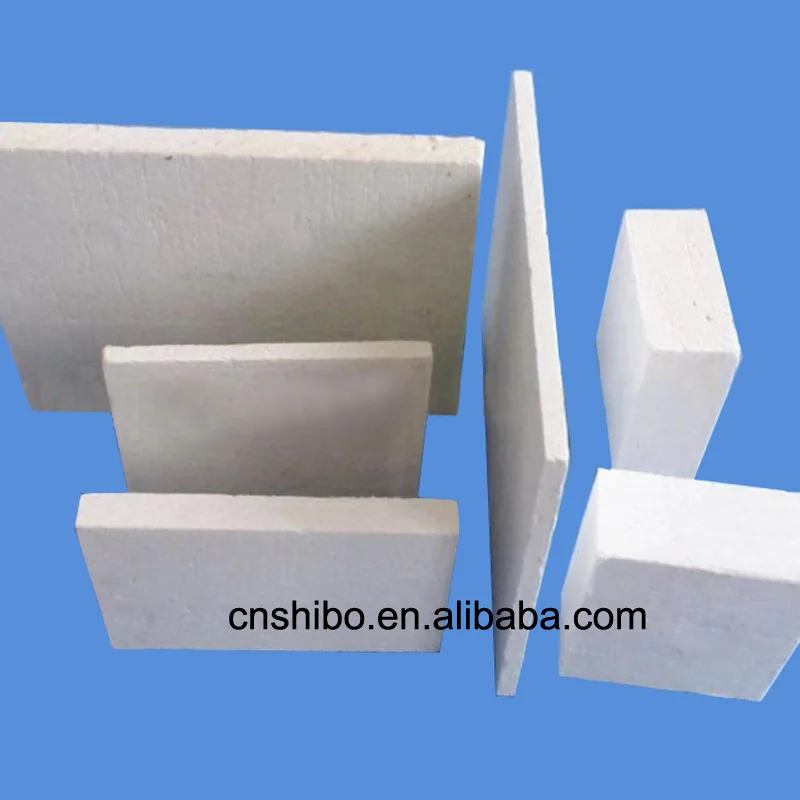

Refractory ceramic fibre board is a vacuum formed product that resists higher gas velocities than ceramic fibre blanket. Ceramic fiber board is ideal for furnace, boiler duct and stack lining due to its low thermal conductivity and low heat storage allowing shorter cycle times and quicker access for maintenance.

Features

1. Low thermal conductivity and low heat storage

2. High temperature stability and resistant to thermal shock

3. High crushing strength and good toughness

4. Allow machining and cutting, easy application

5. Resistant to airflow erosion

Typical Application

1. Hot face lining of ceramic fiber kiln

2. Insulation for kiln car

3. Furnace door insulation

4. Duct insulation

5. General thermal barrier

6. High temperature insulation

| Techincal data of ceramic fiber boards: | |||||||

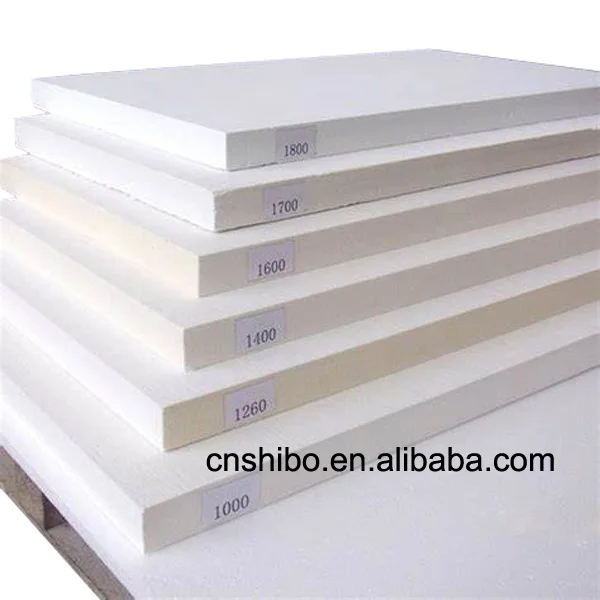

| Classification Temperature ( ℃ ) | 1260 | 1400 | 1500 | 1600 | 1700 | 1800 | |

| Working temperature ( ℃ ) | 1000 | 1200 | 1350 | 1500 | 1600 | 1700 | |

| Color | Pure white | Pure white | Pure white | Pure white | Pure white | Pure white | |

| Density ( kg/m3 ) | 250-400 | 250-400 | 300-400 | 400 | 400 | 400-500 | |

| Thermal Conductivity ( w/mk ) | 400℃ | 0.09 | – | – | – | – | – |

| 600℃ | 0.12 | 0.12 | 0.12 | – | – | – | |

| 800℃ | 0.16 | 0.15 | 0.16 | 0.14 | 0.15 | 0.17 | |

| 1000℃ | – | 0.23 | 0.23 | 0.17 | 0.19 | 0.24 | |

| 1200℃ | – | – | 0.25 | 0.23 | 0.25 | 0.28 | |

| Chemical Composition ( % ) | Al2O3 | 43 | 45 | 60 | 64 | 75 | 80 |

| Al2O3+SiO2 | 98 | 98 | 98 | 98 | 99 | 99.5 | |

| BaO | <0.2 | <0.2 | <0.2 | <0.1 | <0.05 | <0.05 | |

| Fe2O3 | <1.2 | <1.2 | <0.5 | <0.5 | <0.2 | <0.1 | |

| Shrinkage ( % ) | 1100℃×24h -3 | 1200℃×24h -2.5 | 1400℃×24h -2 | 1500℃×24h -1 | 1600℃×24h -0.5 | 1700℃×24h -0.4 | |

| Combustion Loss ( % ) | <=5% | <=5% | <=4.5% | <=4.5% | <=5% | <=3.5% | |

| Compressive Strength ( MPa | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | |

Zhengzhou Shibo Nonferrous Metals Products Co., Ltd, as a high technology enterprise was established in 2005, located in Zhengzhou City, Henan Province, China, with registered capital of RMB 20 million, covered an area of more than 6000 square meters and employee more than 100 peoples, we specialized in tungsten&molybdenum ( powder, sheets, rods wires, parts, etc ), MoSi2&SiC heating elements, alumina ceramic tubes, ceramic fiber boards, high temperature lab muffle furnaces, tungsten copper alloy, including the development, production, and sales, we always provide our customers top quality products and best service.