QT4-15 автоматическая гидравлическая машина по производству Бетонных блоков цена устройство для формирования

- Категория: Brick Making Machinery >>>

- Поставщик: Linyi,Dongyue,Imp.,&,Exp.,Co.,Ltd.Linyi,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 11900.37 $* | 12495.23 $* |

| Aug-18-2025 | 11800.44 $* | 12390.6 $* |

| Jul-18-2025 | 9900.18 $* | 10395.66 $* |

| Jun-18-2025 | 11600.46 $* | 12180.75 $* |

| May-18-2025 | 10100.32 $* | 10605.30 $* |

| Apr-18-2025 | 11400.7 $* | 11970.86 $* |

| Mar-18-2025 | 11300.33 $* | 11865.89 $* |

| Feb-18-2025 | 11200.51 $* | 11760.74 $* |

| Jan-18-2025 | 11100.36 $* | 11655.77 $* |

Характеристики

Product Overview

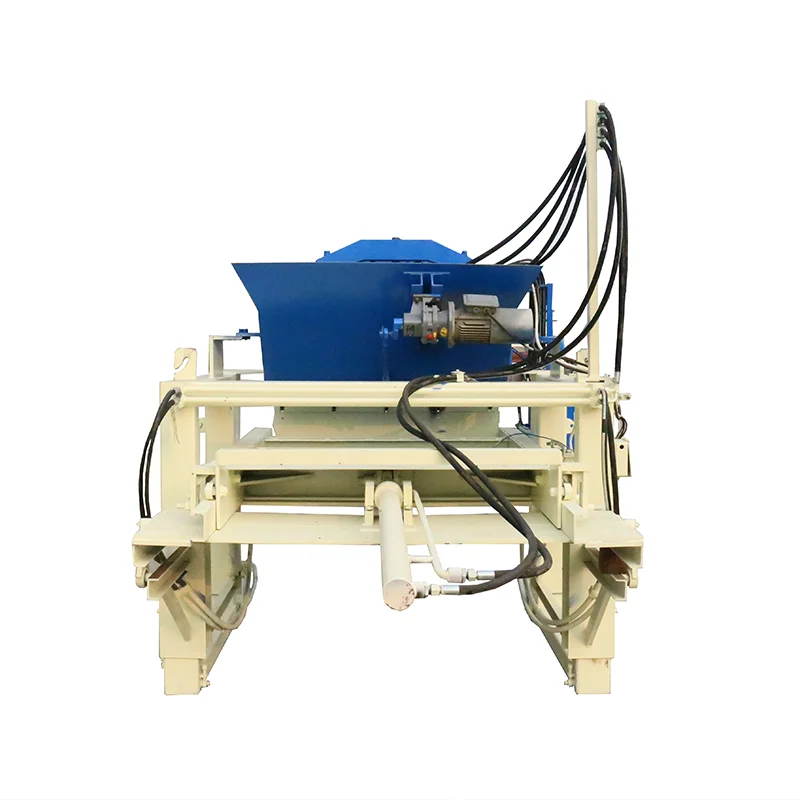

QT4-15 Hydraulic concrete brick machine cement brick making machine

Automatic QT4-15 block making machine can produce all kinds of hollow blocks and solid bricks and color paving bricks,only by changing different moulds.

host machine size | 2700*1600*2500mm | host machine weight | 4.5t |

block making period | 15-20s | pallet size | 880*580*22 |

vibrating force | 30-50kn | Voltage | Adopt to local voltage |

host machine power | 24kw | work shop area | 250-300m2 |

1. This machine is multi-fuctional. Various bricks such as road verge bricks,river channel bricks,slope-protecting bricks,plaza pavement bricks,dock bricks,grass-planting bricks etc. can be produced only by exchanging its mould.

2.By low frequency material feeding,high frequency vibrating and pressing and vibrating both by table and mould, the concrete can be completely liquidized and air discharged within 2 or 3 seconds, in order to obtain high density and high strength.

3.As the advanced hydraulic ratio control technology is adopted so that the oil pressure of each branch of the circuit can be controlled at will and various bricks with the same high quality can be produced using different raw materials.

4.PLC intelligent control system which equipped with data input and output device,advanced safety logic and fault self-diagnosis system is adopted in full of the production procedure.

2.By low frequency material feeding,high frequency vibrating and pressing and vibrating both by table and mould, the concrete can be completely liquidized and air discharged within 2 or 3 seconds, in order to obtain high density and high strength.

3.As the advanced hydraulic ratio control technology is adopted so that the oil pressure of each branch of the circuit can be controlled at will and various bricks with the same high quality can be produced using different raw materials.

4.PLC intelligent control system which equipped with data input and output device,advanced safety logic and fault self-diagnosis system is adopted in full of the production procedure.

Theoretical Production Capacity

Name | block size | block making period | blocks per mold | Production capacity |

Hollow block | 400x200x200 | 15-20s | 4 | 720-960pcs/hour |

Multi-hole brick | 240x115x90 | 15-20s | 12 | 2160-2280pcs/hour |

Solid brick | 240x115x53 | 15-20s | 26 | 4680-6240pcs/hour |

paver | 200x100x60 | 20s | 16 | 2880pcs/hour |

Ishape paver | 200x163x60 | 20s | 12 | 2160pcs/hour |

production process

QT4-15 Block Machine Advantage:

1. Use Germany Siemens PLC control system and Siemens Touch Screen, use Schneider and Omron relays and contactors:

2. Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

3. Visualization touch screen, with easy operation;

4. High-quality electrical components from Schneider and Omron;

5. Use Frequency Conversional Control Technology, which controls the block making:

6. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

7. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

8. Power saving: 30%;

9. Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

10. Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

11. Guarantee production stability;

12. 360° Multi-Shaft Rotating and Compulsory Feeding:

13. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

14. This uniform feeding is applicable for different kinds of raw materials and moulds;

15. Use heat treatment on moulds and main parts of the machines:

16. Heavy duty machine structure and wear resistant moulds;

17. The hardness reaches up to HRC 52-58;

18. Greatly improves the using lifetime of the machine by 50%.

2. Siemens PLC, with great adaptability, guarantees the stability and reliability of the machine.

3. Visualization touch screen, with easy operation;

4. High-quality electrical components from Schneider and Omron;

5. Use Frequency Conversional Control Technology, which controls the block making:

6. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration; increases the production rate by improving the vibrating efficiency;

7. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

8. Power saving: 30%;

9. Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

10. Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

11. Guarantee production stability;

12. 360° Multi-Shaft Rotating and Compulsory Feeding:

13. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed

14. This uniform feeding is applicable for different kinds of raw materials and moulds;

15. Use heat treatment on moulds and main parts of the machines:

16. Heavy duty machine structure and wear resistant moulds;

17. The hardness reaches up to HRC 52-58;

18. Greatly improves the using lifetime of the machine by 50%.

Details images

Material for making blocks

This is the most popular proportion in making block making machine:

1. Standard concrete block: Cement 9-12%, sand 40%, stone 45%, water 3%

2. Light concrete block: Cement 9-12%, slag 80-90%, water 3%

3. Cement 9-12%, sand 10-20%, stone 30-40%, slag 25-50%, water 3%

4. Cement 8%-10%, sand 30%-40%, stone 50%-60%

5. Cement 8%, sand 60%, Fly ash 30%, gypsum 2%.m: +8615092894665(whatsapp,wechat) skype: lyhebe

1. Standard concrete block: Cement 9-12%, sand 40%, stone 45%, water 3%

2. Light concrete block: Cement 9-12%, slag 80-90%, water 3%

3. Cement 9-12%, sand 10-20%, stone 30-40%, slag 25-50%, water 3%

4. Cement 8%-10%, sand 30%-40%, stone 50%-60%

5. Cement 8%, sand 60%, Fly ash 30%, gypsum 2%.m: +8615092894665(whatsapp,wechat) skype: lyhebe

Block samples

Company Introduction

Contact Us