Полностью автоматический гофрированный флексографский принтер со слотами и штамповочным резаком для мини-картона

- Категория: Carton Printing Slotting Die-Cutting Machine >>>

- Поставщик: Hangzhou,Royal,Packing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 94248.62 $* | 98960.25 $* |

| Aug-16-2025 | 93456.3 $* | 98129.3 $* |

| Jul-16-2025 | 78408.90 $* | 82328.18 $* |

| Jun-16-2025 | 91872.10 $* | 96466.93 $* |

| May-16-2025 | 79992.14 $* | 83992.25 $* |

| Apr-16-2025 | 90288.20 $* | 94802.57 $* |

| Mar-16-2025 | 89496.25 $* | 93971.61 $* |

| Feb-16-2025 | 88704.93 $* | 93139.4 $* |

| Jan-16-2025 | 87912.71 $* | 92308.64 $* |

Характеристики

This machine is with vacuum absorption auxiliary feeding system. (The wind strength can be adjusted). It can Printing, slot, cut the corner, cut the extra side and press the lines of the corrugated cardboard. The slotting width is electric adjustment, and it attached a ruler that the scale can be read easily. The phase adjustment of slotting part is planetary gear structure. The machine adopts 360°electric adjustment. The up and down slotting knives and creasing knives can move synchronously (use exclusive tool to adjust left and right). This small machine is easy to operate and repair easily which is specialized for slotting small boxes.

1. Feeding paper roller adopt patterned roller, feeding paper roller pressure adjustment adopt eccentricwheel adjust and left-right eccentricwheel, adjust the pressure synchronous

2. Pushing paperboard department adopt both sides baffle and latter baffle to fasten paperboard, to avoid the slotting error when pushing paperboard which make upper paperboard misplace, can fit to every kinds paperboard, and sending paper stable and accurate.

3. Slotting plate adopt full steel processed accessories, slotting knives adopt zigzagarc-shaped semicircle knives to slot and remove the scrap, paperboard get into slitting roller after slotting, slitting knives slit both sides of the paperboard(note:pressing wheel and slitting knives in one roller)

4. Paperboard is send out by six transmit shaft after slotting, corner-cutting, slitting, pressing, this machine power equipped with the frequency conversion speed regulator(speed adjustable freely), adopt Jintiao frequency converter.

5. This machine adopt electric planetary gear phase to adjust paperboard size, can adjust without stopping.

Auto Feeding Unit

Feeding paper roller adopt patterned roller, feeding paper roller pressure adjustment adopt eccentric wheel adjust and left-right eccentric wheel, adjust the pressure synchronous

Printing Unit

Adopts Φ218mm high quality thick seamless steel tube which is surface grinding and hard chromium plating.

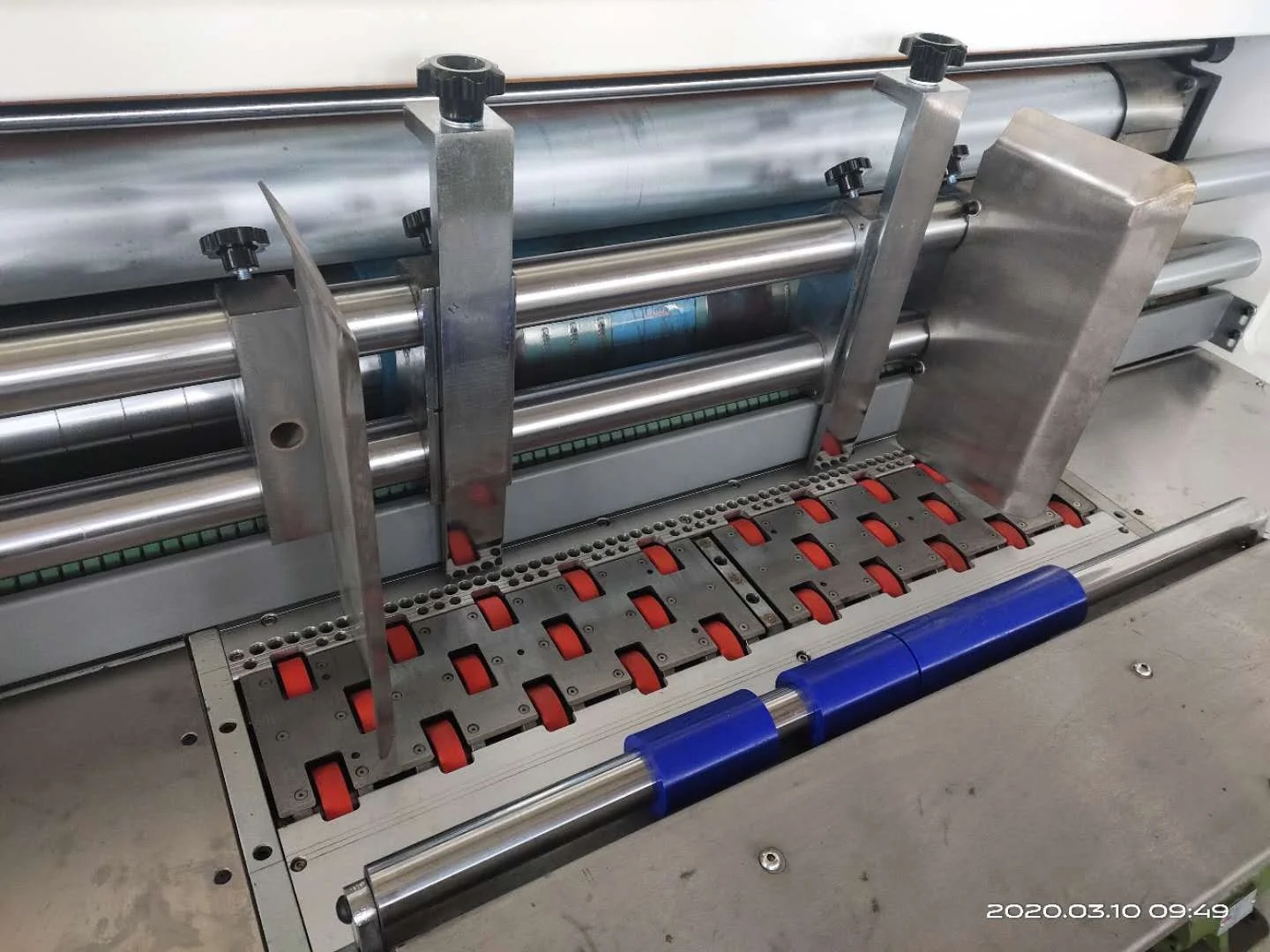

Slotting Unit

Slotting plate adopt full steel processed accessories, slotting knives adopt zigzagarc-shaped semicircle knives to slot and remove the scrap, paperboard get into slitting roller after slotting.

Die-cutting Unit

Rubber mat roller (Upper roller):

* Diameter of roller:281mm

* Cast iron material with surface grinding and hard chromium plating

* Diameter of roller:281mm

* Cast iron material with surface grinding and hard chromium plating

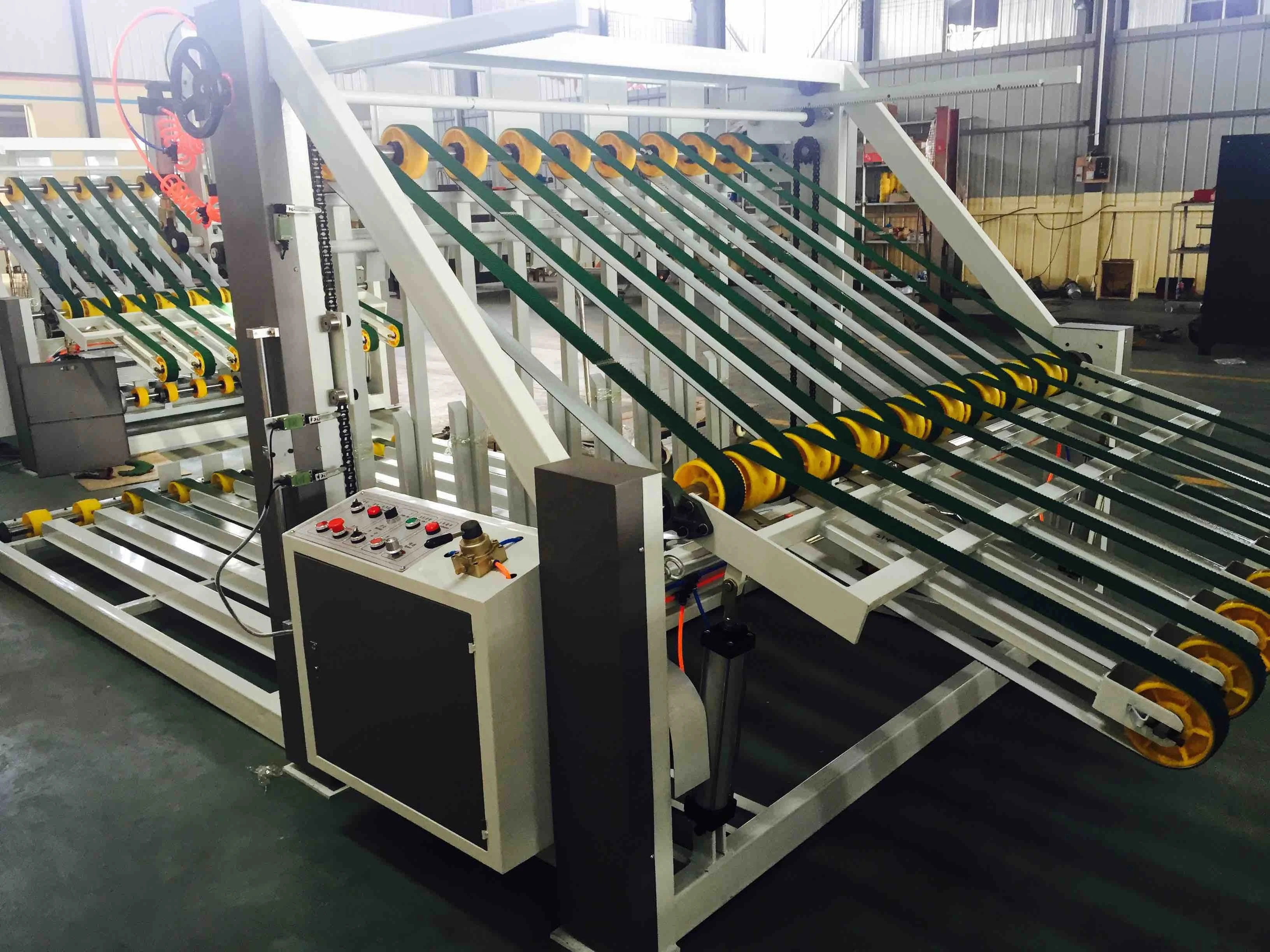

Stacking Unit

The receiving paper arm adopt auto and manual operation with safe structure to avoid receiving paper arm suddenly drop and hurt operator.

RDC Mould

For different types of cartons.

Model | RYKS 282 | RYKS 270 | ||

Max machine speed | 150-200 pieces/min | 150-200 pieces/min | ||

Max feeding size (L * W) | 2300*900mm | 2300*800mm | ||

Width of printing roller | 2200mm | 2200mm | ||

Min feeding size (L * W) | 600mm*230mm | 600mm*210mm | ||

Min slotting interval | Negative knife (A * B) | 230mm*60mm | 230mm*60mm | |

Min height of box (H) | 115mm | 115mm | ||

Dimension (Length*Width*Height) | 4700mm*4500mm*2000mm | 4700mm*4500mm*2000mm | ||