Завод по производству цемента линия

- Категория: Cement Making Machinery >>>

- Поставщик: Henan,Fantianliang,Machinery,&,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 65573998.99 $* | 68852698.22 $* |

| Aug-17-2025 | 65022956.37 $* | 68274104.64 $* |

| Jul-17-2025 | 54553158.75 $* | 57280816.83 $* |

| Jun-17-2025 | 63920872.21 $* | 67116916.8 $* |

| May-17-2025 | 55655242.2 $* | 58438004.11 $* |

| Apr-17-2025 | 62818788.26 $* | 65959727.35 $* |

| Mar-17-2025 | 62267746.35 $* | 65381133.56 $* |

| Feb-17-2025 | 61716704.70 $* | 64802539.9 $* |

| Jan-17-2025 | 61165662.13 $* | 64223945.65 $* |

Характеристики

Products Description

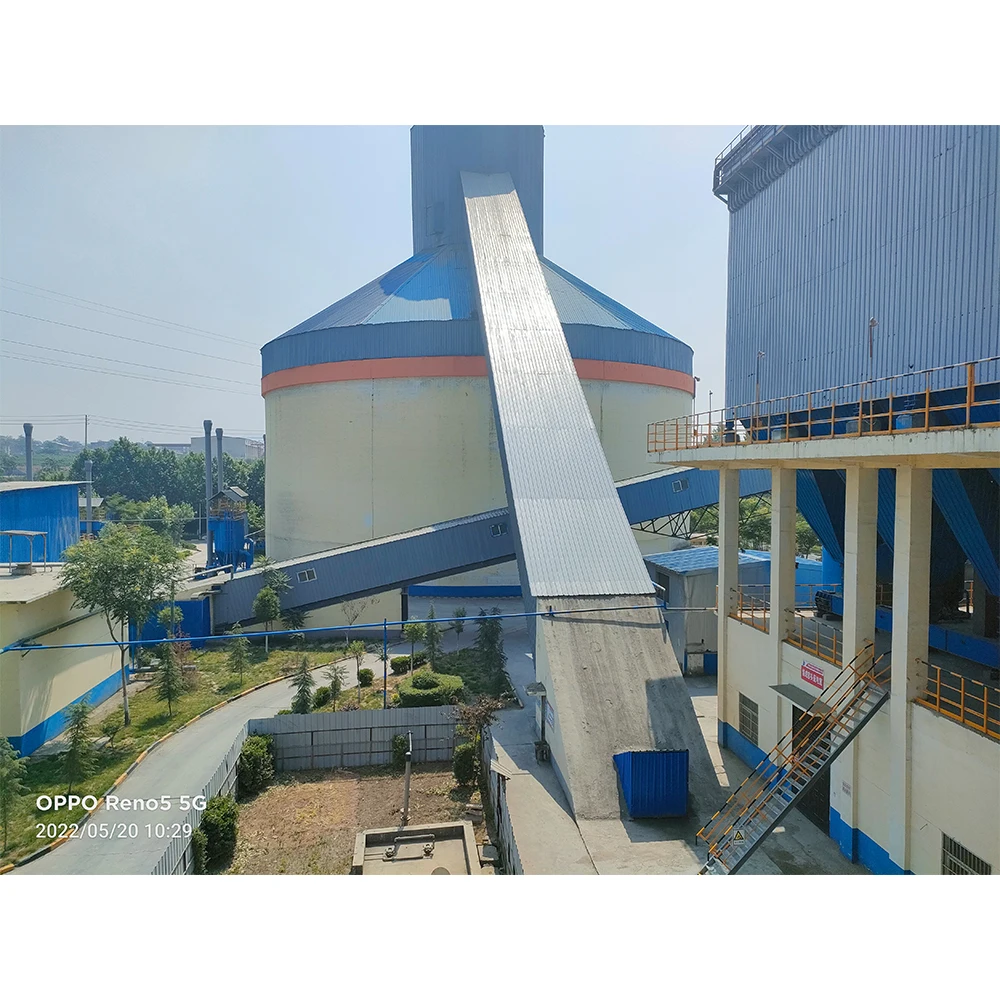

Project case 350T Per Day cement production plant in UZ KZ Russia / cement machine line/cement plant machine

Working principle of Cement Making Machine

Cement Making Machine is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Our Projects

Main equipment

1 | limestone crushing |

2 | raw material storage and blending |

3 | raw material grinding |

4 | raw material homogenizing and kiln feeding |

5 | kiln inlet, kiln middle, kiln head and pulverized coal preparation |

6 | waste gas treatment at kiln inlet |

7 | clinker and admixture storage |

8 | cement grinding |

9 | cement storage and packing |

Производительность клинкера | 300 т/сутки | 700 т/сутки | 1000 т/сутки | 1500 т/сутки | ||

Подогреватель | C1 | 2-Φ2500 | Φ3500 | Φ4800 | 2-Φ4000 | |

C2 | Φ3600 | Φ4800 | Φ4800 | Φ5800 | ||

C3 | Φ3600 | 2-Φ3700 | Φ5200 | Φ5800 | ||

C4 | Φ3600 | Φ4800 | Φ5200 | Φ6200 | ||

C5 | Φ3600 | Φ4800 | Φ5200 | Φ6200 | ||

Подогревательная печь | Модель | Φ2200 | Φ2800 | Φ4800 | Φ5200 | |

Вращающаяся печь | Модель | Φ2.8×44м | Φ3×48м | Φ3.2×50м | Φ3.5×54м | |

Производительность | 12.5 т/ч | 30 т/ч | 42 т/ч | 63 т/ч | ||

Температура обжига (℃) | 1450 | 1450 | 1450 | 1450 | ||

Сырьевая мельница | Модель | Вертикальная роликова мельница Φ1700 | Сухая мельница Φ3.2×7+1.8м | Сухая мельница Φ3.5×10м | Вертикальна роликова мельница HRM2800 | |

Производительность | 30 т/ч | 50 т/ч | 85 т/ч | 130~160 т/ч | ||

Мощность | 400 кВт | 1000 кВт | 1250 кВт | 1250 кВт | ||

Цементная мельница | Модель | Φ2.4×13м Незамкнутая цепь | Φ3×11м Замкнутыйтая цепь | Φ3.2×11м Замкнутыйтая цепь | Φ4.2×13.5м Замкнутыйтая цепь | |

Производительность | 22 т/ч | 42 т/ч | 64 т/ч | 95 т/ч | ||

Мощность | 800 кВт | 1250 кВт | 1400 кВт | 3550 кВт | ||

Packing and shipping

Company Profile

About us

Our company covers an area of 50,000 square meters, including 15,000 square meters of modern buildings. We have adopted the scientific management mode of modern enterprises, and constantly strived to create novel products. As a result, our company has become a famous enterprise of machinery industry in China.With many years' development, we have accumulated rich experience in the production and management, and brought up a large number of technical members and management elites. Nowadays, we have 660 employees, including 180 senior and intermediate technical members.

Through constant introduction, digestion and absorption, our company has 100 sets of various large and medium equipment and several workshops for casting, forging, thermal treatment, machinery processing, welding, assembly, and machine repair. The maximum capability of assembly lift is 120MT.

Through constant introduction, digestion and absorption, our company has 100 sets of various large and medium equipment and several workshops for casting, forging, thermal treatment, machinery processing, welding, assembly, and machine repair. The maximum capability of assembly lift is 120MT.

Our service

* 24 hours online customer service, detailed and professional solution.

* Skilled engineers, scene investigation, free customized program solution.

* The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

* After-sales service support, Expert technical training and operating instructions, site installation and commissioning, adhere to test equipment and visit our customers regularly.

* We offer all kinds of models, high-quality crushing and screening equipment parts.

* Skilled engineers, scene investigation, free customized program solution.

* The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

* After-sales service support, Expert technical training and operating instructions, site installation and commissioning, adhere to test equipment and visit our customers regularly.

* We offer all kinds of models, high-quality crushing and screening equipment parts.