Коррозионная стойкость 2 л реактор из жакетированного стекла для синтезированной

- Категория: Reactors >>>

- Поставщик: Zhengzhou,Obor,Instrument,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.12 $* | 0.71 $* |

| Aug-16-2025 | 0.78 $* | 0.73 $* |

| Jul-16-2025 | 0.14 $* | 0.28 $* |

| Jun-16-2025 | 0.36 $* | 0.47 $* |

| May-16-2025 | 0.59 $* | 0.75 $* |

| Apr-16-2025 | 0.21 $* | 0.73 $* |

| Mar-16-2025 | 0.70 $* | 0.42 $* |

| Feb-16-2025 | 0.43 $* | 0.57 $* |

| Jan-16-2025 | 0.29 $* | 0.24 $* |

Характеристики

Details and Features

CONTANT PRESSURE DROP FUNNEL

REFLUX HEAD

of the experiment, but also

sampling and recycling.

CONTANT PRESSURE DROP FUNNEL

The drop funnel is used for volatile, reactive substances exposed to air,or when the rate of drop is maintained.

CONTANT PRESSURE DROP FUNNEL

The drop funnel is used for volatile, reactive substances exposed to air,or when the rate of drop is maintained.

High borosilicate glass G3.3 has low thermal expansion coefficient, high temperature resistance, corrosion resistance and other characteristics, can be widely used in chemical, aerospace, military, family, hospital and other fields

Wide Range of Application

Glass reactor is mainly used for material synthesis, distillation, concentration and other experiments. It is widely used in pharmaceutical and chemical industries, especially in drug synthesis, fine chemical industry, petrochemical process and new material synthesis,etc.

Optional Functions

Glass seal plug Insulation clothes Ex-proof Motor and controller Multiple stirring blades

Technical Parameter

Model | JGR-1L | JGR-2L | ||||

Reaction capacity | 100ml~1L | 200ml~2L | ||||

Jacketed volume | 1L | 1.3L | ||||

*Voltage | 220V/50Hz【110V/60Hz optional】 | |||||

*Motor power | 120W | |||||

Rotating speed | 0-1200rpm | |||||

Controller | Temperature, speed LCD digital display, speed knob adjustment, with PT100 probe | |||||

Control precision | ±1℃ | |||||

Temperature range | -120℃~300℃ | |||||

Working pressure | -0.1Mpa~0.1Mpa | |||||

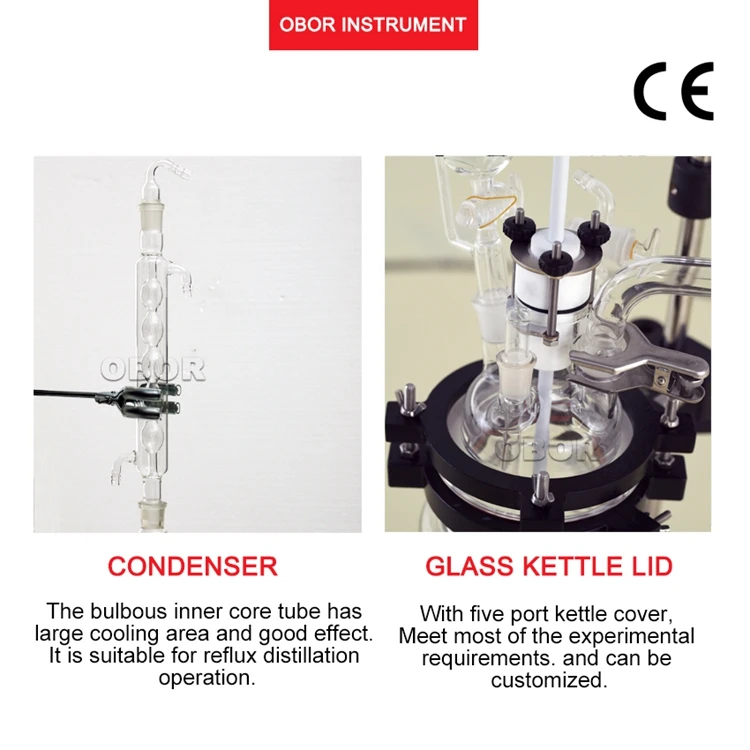

Glass lid With *five port φ150mm | Stirring | 50 Flange | ||||

Reflux/Condenser | 35# ball-mill joint / 24# standard ground joint | |||||

Drop funnel | 24# standard ground joint | |||||

Multi-function manual valve | 24# standard ground joint | |||||

Thermometer tube | 19# standard ground joint | |||||

Stirring PTFE seal | The inner oil seal, O-ring and bearing | |||||

Condenser | Spherical condenser | |||||

Reflux Head | Not only ensure the continuity of the experiment, but also sampling and recycling. | |||||

Constant pressure drop funnel | 250ml | |||||

Multi-function manual valve | Used for adding liquid, venting air or filling nitrogen | |||||

Discharge valve | PTFE; No blind Angle; ID6mm, OD12mm | |||||

*Stirrer blade type | PTFE, Four-blade | |||||

Fixed parts | Aluminum alloy( For kettle body and kettle cover) | |||||

Tray | Aluminum alloy( For kettle body) | |||||

Inlet/outlet oil port | Pagoda joint / Ball-mill Joint | |||||

Hexagon wrench | Some | |||||

SS304 Stainless steel base | 350*330mm | |||||

Machine size | 440L*360W*1325H mm | |||||

Remark: The parameters with"*"have more selectivity | ||||||

Auxiliary Equipment Recommendation

At the same time of material mixing, which can be heated or cooled at constant temperature by circulating hot solution or coolant through the jacketed layer. When the material is heated, the evaporation efficiency can be improved under vacuum condition (vacuum device should be connected). The condenser with a chiller to work together, the cooling effect will be better. Before choose the device, please inform us of the purpose of use and target temperature, so that we can recommend the suitable model for you.

Company Profile

Our company is located in Gongyi City, Zhengzhou, Henan Province, with beautiful scenery. It is a scientific research, design, sales and maintenance company with a variety of technology. The company will take quality as the foundation, credibility for survival, and service for development as its goal. We will work hard both physically and mentally, and cooperate with all the employees to abide by the contract and guarantee the quality of the products. With a variety of operation features and the principle of profit and consumption, We will treat each client equally, establish a win-win system, complement each other's advantages with the society and create glory at the same time!

After-sales service: - One year for whole instrumen from the delivery date - Lifetime service for whole equipment - 18 hours technical support by e-mail or video call or calling service - Transport breakage, photo confirmation, free replacement | Customized Service: - Tell us your work flow and special requirements - Solution+Drawing - Poduction+Test |

OEM Service - Your company information and requirements - Design label+ Discussion - Confirmation+Print | Shipping Service - Export wooden cases or carton case - Fumigation certification, certification of original - We can ship goods by sea, by air, by train, smaller goods or spare parts will be shipped by express - You can choose to use your own forwarder |

Manufacturing Technique

Our Advantage

1.Plant direct supply, Highly competitive prices2.The experienced staff will give you a good shopping experience

3.Strict quality control, professional merchandisers to the factory for inspection

4.Effective OEM&ODM service

5.Diversification of products and services

Packaging & Shipping

Our company's glass and other fragile parts are wrapped with cushioning bubbles, stainless steel and other accessories are wrapped with winding film, and then placed in the wooden box. The wooden case is filled with pearl cotton around and the parts and accessories are separated again with pearl cotton, which is enough to protect the safety of products. If the glass products are damaged due to the transportation,which undertaken by our company, please submit it to us within three days after receiving the goods and keep the original packaging and debris for future reference, and replace them free of charge after verification. (except for transportation carried by customers)

FAQ

A)Are you manufacturer or trading company?

We are professional manufacturer of glass reactor series and chiller, heater, high and low temperature circulating device. Other products work directly with manufacturers.

B)How to guarantee the quality of your products?

1) Strict detection during production.

2) Strict sampling inspection on products before shipment and intact product packaging ensured.

We are professional manufacturer of glass reactor series and chiller, heater, high and low temperature circulating device. Other products work directly with manufacturers.

B)How to guarantee the quality of your products?

1) Strict detection during production.

2) Strict sampling inspection on products before shipment and intact product packaging ensured.

C) How to choose suitable equipment?

You tell us your work flow and special requirements (For example: capacity, temperature range, pressure, power supply, etc ), we will recommend you suitable equipment according to your requirements,application experience and feedback from our clients.

You tell us your work flow and special requirements (For example: capacity, temperature range, pressure, power supply, etc ), we will recommend you suitable equipment according to your requirements,application experience and feedback from our clients.

D)How long is your date of delivery?

Within 5 working days after payment confirmed, customized products need 10~15 working days.

Within 5 working days after payment confirmed, customized products need 10~15 working days.

E)How to solve the equipment trouble during using?

Please send us email of the problem, pictures or a small video will be much better, we will find the problem and help you to solve it. If there is a broken, we will send you a new part via express, and it is free in the warranty period.

Please send us email of the problem, pictures or a small video will be much better, we will find the problem and help you to solve it. If there is a broken, we will send you a new part via express, and it is free in the warranty period.

F)Will you provide service beyond the warranty?

Yes. We provide lifetime service for our products, but it won’t be free beyond the warranty period.

Yes. We provide lifetime service for our products, but it won’t be free beyond the warranty period.