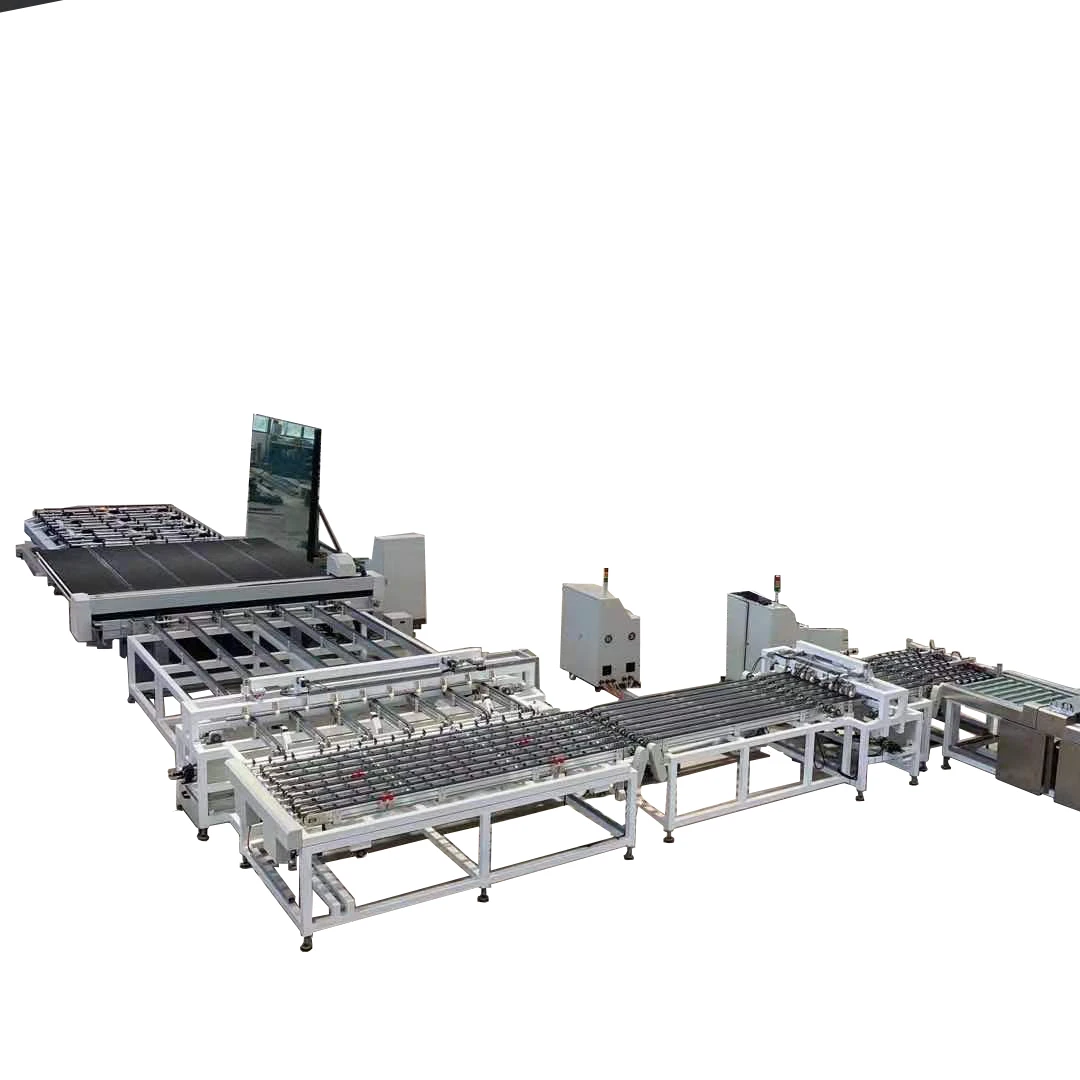

Автоматический разрыв стекла для интеллектуальной

- Категория: Glass Product Making Machinery >>>

- Поставщик: Anhui,Ruilong,Glass,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 135065.61 $* | 141818.31 $* |

| Aug-17-2025 | 133930.55 $* | 140627.70 $* |

| Jul-17-2025 | 112365.16 $* | 117983.43 $* |

| Jun-17-2025 | 131660.58 $* | 138243.23 $* |

| May-17-2025 | 114635.96 $* | 120367.73 $* |

| Apr-17-2025 | 129390.18 $* | 135860.59 $* |

| Mar-17-2025 | 128255.86 $* | 134668.81 $* |

| Feb-17-2025 | 127120.1 $* | 133476.10 $* |

| Jan-17-2025 | 125985.98 $* | 132284.75 $* |

Характеристики

Buyer also purchase those

Product Description

Specification

item | value |

Applicable Industries | Manufacturing Plant |

Showroom Location | None |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | Ordinary Product |

Warranty of core components | 1 Year |

Core Components | Motor, Pump |

Condition | New |

Production Capacity | 2 pcs/10s |

Place of Origin | China |

Power | 42kw |

Weight | 2800kg |

Warranty | 1 Year |

Key Selling Points | smart |

Product name | Automatic glass breaking line |

Processing range | 3660*2440mm |

Automatic glass loading machine | included |

Automatic glass cutting machine | included |

Horizontal glass breaking machine | included |

Vertical glass breaking machine | included |

Glass washing machine with air knife | included |

SY-4028 double-turn single-station loading Machine

1.1 Equipment configuration

1), equipment main frame/equipment walking system/equipment transmission system/vacuum adsorption system/mechanical turning system/High and low voltage control system/program control system.

1.2 Mechanical configuration:

1), Flip sprocket chain: special high-precision reinforced type.

2), transmission roller: imported PU material.

3), vacuum suction cup: imported nitrile rubber material (double adsorption structure)

4) Transmission/flipping motor: Chengbang Motor

5), vacuum pump: Sino-German joint venture PUXU.

1.3 Original electrical parts:

1), PLC controller: Delta

2) Frequency converter: Delta

3) Proximity switch: Suoneng

4), control cable: flexible shielded cable.

5), contactor: Schneider.

6) Pneumatic components: The main components are from Taiwan Yadike.

7), positive and negative pressure sensor: Japan SMC

1.4 Technical parameters:

1), the size range of the top sheet: the minimum size of the top sheet: 1500*1500mm (only on the left side)

Maximum loading size: 4000*2800mm

2), the thickness of the top sheet: 2~8mm.

3), loading cycle: 40-90 seconds (adjustable)

4) Transmission speed: 0~40m/min (adjustable)

5), the maximum suction depth: 600mm

6), the maximum loading load: 400KG

7), the number of unilateral upper arm: four arms.

8) The number of single-arm suction cups: three.

9), upper flip arm: double flip

10), loading station: single station

11), power supply/power Installation power supply: 380V/50HZ (special circumstances can be adjusted according to customer requirements)

12), installation power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14), vacuum pressure: -70~ -90Kpa (adjustable according to glass thickness)

2. Technical information:

2.1. Machine overview:

1) The automatic loading machine is an auxiliary equipment that extracts the original glass sheet from the material rack, turns it over to the water platform, and transports it to the cutting machine or other processing table.

2) The vacuum system adopts a well-known brand vacuum pump, which greatly improves the safety and stability of the whole system; the main body of the frame is driven by a motor to move on a double track, and the main frame arm is equipped with suction cup arms, each of which has three The suction cup is adjustable. The frame moves forward and the suction cup arm flips up at the same time. When the suction cup touches the original glass on the glass frame, the vacuum pump starts to work, and the suction cup generates a vacuum to suck the glass. When the vacuum degree reaches the set value, the flip arm lifts and flips to Horizontal position, after exhausting, the glass will be conveyed to the end of X axis and positioned, waiting to be conveyed to the cutting machine. The whole operation process is controlled by PLC.

2.2 Technical description

1) Flip mode: mechanical flip, fast running speed, stable operation, no jitter, and can meet the glass loading of 3~8mm. Equipped with double-track overturning transmission chain protection to ensure the safety and reliability of the overturning process,

2) Flip angle: 95~98 degrees adjustable. It can meet various angles of glass racks.

3) Suction depth: With special connecting rod telescopic mechanism, the suction cup can extend forward up to 150mm, which can meet the loading depth of 600mm. It can be loaded directly from the iron frame without any auxiliary frame.

4) Induction device: use two sets of glass photoelectric sensors (one set for use and one set for standby), which can effectively prevent safety accidents caused by induction failure. Equipment operation is more secure, stable and reliable.

5) Lifting device: The unique connecting rod lifting device can ensure that the lifting action is synchronous and consistent, and eliminates the defect of asynchronous lifting. Guaranteed safe slicing of glass.

6) Adsorption device: The suction cup adopts an advanced double-layer adsorption structure (two layers inside and outside), and the suction sheet is firmer, eliminating the defect of adsorption and air leakage caused by the scratching of the outer layer of the suction cup.

7) Suction cup control: Each suction cup has a separate air valve for on-off control, and the number of suction cups can be freely selected, which is convenient for the operation requirements of various sizes of glass.

8) Protection of wrong piece lifting: The unique lifting protection device of the equipment can effectively prevent the glass

breakage caused by the failure of the glass to be timely and wrong.

9) Alarm device: with automatic detection and traffic light alarm device, it can automatically alarm and display abnormal

conditions. Equipped with an emergency stop switch, which can be controlled in the event of an abnormality.

10) Operation mode: The device has two functions: automatic mode and manual mode. Easy and intuitive operation

11) Operation interface: It adopts color LCD touch screen display interface and Chinese and English display modules, which is convenient and quick to operate.

12) Parameter setting: The sequence of film loading and the number of films loaded at each station can be automatically set digitally, and it can be fully connected to the cutting machine. , more convenient and faster.

SY-4028 automatic cutting machine

Basic performance:

1. Equipment specifications:

★Maximum size of cutable glass: 4000*2800mm

★Workbench height: 900±30mm.

★Equipment weight: 2.5T.

★Cutting thickness: 2~10mm

2. Cutting parameters:

★ Linear parallelism: ≤±0.25mm/m

★ Diagonal line precision: ≤±0.35mm/m (the above precision is subject to the cutting line precision before breaking pieces)

★ Cutting bridge speed: 0~180m/min. (adjustable)

★ Cutting bridge acceleration ≥3.0m/s²

★ Tool head frame speed ≥180m/min

★ Tool head frame acceleration ≥6.0m/s²

★ Belt transmission speed ≥40m/min

★ Cutting head positioning accuracy error ≤±0.2 mm

3. Power/Power:

★ Installation power requirements: 380V/50HZ

★ The actual power of the equipment: 8KW.

★Compressed air: 0.6MPA.

4. Equipment performance

★Equipment frame: The equipment has undergone aging treatment to ensure that the table is not deformed and the parallelism is accurate.

★Cutting knife holder: the knife head can be rotated 360 degrees, up and down cutting (can accurately cut any straight line and various special-shaped glass)

★Mesa: Welded by steel plate. High flatness, not easy to deform. .

★Felt: Imported industrial felt (fiber and wool components) with good flatness, anti-static, and reduce glass scratches.

★ Oil supply method: Pneumatic automatic oil filling, synchronized with the lower knife.

★Conveying device: synchronous belt conveys automatically.

5. Mechanical part

★ Platen: steel plate. (flatness≤±0.20mm/m).

★Rack: Japan KHK.

★ Transmission belt/pulley: Barbery

★Cutter/Clamp: Tungsten steel with high penetration.

6. Electrical part

★Use the computer to control directly, the Microsoft Windows interface.

★Voltage: 380V/50HZ. Equipment with transformer.

★Motor: Japan Yaskawa servo motor.

★Proximity switch: Xinling Electric

★Control card: imported from the United States, Galil

★Main electrical components: Relay Chint.

★Pneumatic proportional valve: Japan SMC

7. Software

★Your friend (optional)

★The optimization software and the production management software can be used together.

★With the lower knife limit protection function.

★It can automatically calculate the production capacity function.

★With more than 2000 kinds of cutting gallery. (convenient for drawing and operation)

★Compatible with AUTO CAD drawing software.

★The optimization software is directly compatible with the cutting software.

★With automatic correction function. Ensure cutting accuracy.

★Cut path selection function. Ensure optimum cutting speed.

★Automatic adjustment of cutting knife pressure, fast, accurate and stable.

★Automatic pressure for special-shaped cutting, which can quickly and effectively ensure the cutting effect.

★Origin correction function. The origin can be set twice.

★ Operation input: keyboard and mouse. Chinese/English dialogue interface

★With special-shaped cutting knife pressure automatic adjustment function, to ensure the best cutting effect.

★Special-shaped template scanning: It has the function of converting various (including special-shaped) templates into CAD graphics after point-by-point scanning.

★Optimization software: It can sort the cutting size in any combination, output the best cutting plan, and improve the cutting rate. And it has the function of manual modification in the software after optimization. Effectively improve cutting utilization.

★Optimized pressure and speed: According to the pattern, straight line, arc, inner curve, outer curve starting point and end

point; automatic optimization and adjustment of acceleration section, deceleration section, etc. to output the most suitable pressure and speed.

★Shaped Gallery: Contains more than 300 kinds of special-shaped software gallery, this gallery can meet the needs of all

possibilities.

★Chinese operation interface: the man-machine dialogue should adopt the full Chinese menu.

★Drilling positioning function: The special-shaped library provides the drilling pre-positioning function.

★Protective function of cutter head: It has the function of mechanical protection to eliminate all possibility of collision.

★Special-shaped cutting: The equipment can accurately and automatically cut any straight line, oblique line or special-shaped.

★Belt conveying: The motor directly drives the belt to convey the cut glass to the peeling table.

★Stroke protection: The maximum stroke of the equipment has double protection of mechanical and electrical.

★Cutting pressure adjustment function: Any cutting pressure adjustment can be directly adjusted by the keyboard without manual operation.

Fully automatic horizontal breaking machine

Features

The machine adopts the rollers that ride across the cutting line on the top, and the ejector mechanism on the bottom. Both top and bottom are pneumatically controlled. According to the collected data signals, the cut glass is broken. The broken glass is transferred to the second section of the machine. After entering the second section completely, the lateral transfer rubber roller is lifted to transfer the glass to the longitudinal breaking machine.Changing product specifications requires manual adjustment of the positioning position.With edging system. Pneumatic control of the edger system. Minimum edge margin 15--20mm

Configuration:

Frame: GB square tube welding

PLC+touch screen Delta

Cylinder: AirTAC Adjustable Cylinder

Roller: Homemade POM Wheel

Transmission timing belt: Shanghai

Transfer roller: optical axis and polyurethane roller.

Program: self-designed

Processing parameters

Processing range:The maximum bearing original film is 3660*2440mm;

Product range: 300*300---500*500mm (different specifications, need to manually adjust the position of the positioning block)

Thickness: 2--5mm

Beat: about 10 seconds a piece.

Power: 3kW

Fully automatic vertical breaking machine

Features

The same as the horizontal breaking machine. Double channel discharge.

Configuration:

Frame: GB square tube welding

PLC+touch screen Shenzhen

Cylinder: domestic adjustable cylinder

Roller: Homemade POM Wheel

Transmission timing belt: Shanghai

Transfer roller: 30 optical axis and polyurethane roller.

Program: self-designed

Processing parameters

Processing range: 300*300---500*500mm

Beat: about 10 seconds for two pieces

Power: 3kW

SY-800-2 glass washing machine with air knife

Structure introduction:

* The equipment is 2-stage cleaning; the second-stage cleaning requires industrial grade pure water.

* work process:

Feeding section————The first section of water high pressure spray cleaning 2 pairs of brushes pre-cleaning——a pair of air knife cutting water——main cleaning + 3 pairs of hair brushes + 3 pairs of air knife air drying + oven drying—— discharge section

* General structure:

1 Feed end (800mm);

2 The second pre-cleaning section; the length is about 400mm; two pairs of brushes; the water tank is automatically replenished from the next water tank; independent water tank. A pair of air knives cut the water.

3 main cleaning sections; three pairs of brush cleaning; water temperature controllable;

4 Air-drying section: three pairs of air-knife air-drying; high-pressure air-knife + oven;

5 discharge section (600mm).

* Structural details:

* The national standard square tube frame; all stainless steel casings; the equipment is a segmented structure

* Each section has an independent water tray to achieve independent circulation of each section. and can be automatically supplemented from the back end to the front end

* Conveyor/roller: silicone rubber roller; stainless steel shaft head;

* This equipment is designed to be driven by dense rollers, with a large processing area, and the glass can be cleaned by

circulating water at one time. Roller spacing 120mm; minimum glass 300*300mm

The transmission mode is bevel gear transmission, which has the advantages of stable, durable and reliable structure

The drive is a variable frequency motor, controlled by PLC; one-button start, adjustable transmission speed

* Set various parameters directly on the touch screen.

* Each section of water inlet pipe is equipped with a T-type filter, which can filter fine particles; the second section has a

water heating system.

* Each water tank is equipped with a liquid level meter at the water inlet and outlet, which can automatically replenish and

drain water.

Basic parameters:

Glass size range 300*300—500*500mm;

* Water pump: 150w, 380v stainless steel self-priming pump

* Gear motor: 1.5kw, 380v Guangdong

* Weight: 1200KG

* Dimensions: 2800×1500×2200 (mm) (estimated)

* Equipment transmission roller height: 850 plus or minus 50mm

Glass cleaning range: 0.5—6.mm

* Cleaning speed: 0--6m/min

Water temperature range: room temperature - 45 degrees Celsius

basic configuration

* Water tank, cleaning and drying section cover: 304 stainless steel

* Brush: Dupont silk

* Transmission roller: optical axis + rubber sleeve or rubber roller

* Fan: 380V, 18KW high pressure fan

3-phase asynchronous motor: 1.5kw, 380v (variable frequency speed regulation) Guangdong

* Water pump: 150w, 380v stainless steel self-priming pump

* Gear motor: 1.1kw, 380v Guangdong

* Inverter: Delta

* PLC: Delta

* Touch screen: Delta

* Frame GB square tube

* Side plate stainless steel bending

* Cleaning section pole Cold-drawn plate electroplating hard wrap

* The upper platen in the cleaning section, aluminum finishing and oxidation

* Electrical parts: Chint

Equipment requirements for glass:

1 Water-based cutting fluid is required for cutting

2 The suction cup of the loader is a non-marking suction cup

3 No organic matter adhesion

Acceptance Criteria:

1 No visible pollution, impurities, water marks, scratches

2 No visible pollution, impurities, water marks, scratches under incandescent lamps;

3 The cleanliness meets the cleanliness required by hot bending; the pass rate is 99.9%

1.1 Equipment configuration

1), equipment main frame/equipment walking system/equipment transmission system/vacuum adsorption system/mechanical turning system/High and low voltage control system/program control system.

1.2 Mechanical configuration:

1), Flip sprocket chain: special high-precision reinforced type.

2), transmission roller: imported PU material.

3), vacuum suction cup: imported nitrile rubber material (double adsorption structure)

4) Transmission/flipping motor: Chengbang Motor

5), vacuum pump: Sino-German joint venture PUXU.

1.3 Original electrical parts:

1), PLC controller: Delta

2) Frequency converter: Delta

3) Proximity switch: Suoneng

4), control cable: flexible shielded cable.

5), contactor: Schneider.

6) Pneumatic components: The main components are from Taiwan Yadike.

7), positive and negative pressure sensor: Japan SMC

1.4 Technical parameters:

1), the size range of the top sheet: the minimum size of the top sheet: 1500*1500mm (only on the left side)

Maximum loading size: 4000*2800mm

2), the thickness of the top sheet: 2~8mm.

3), loading cycle: 40-90 seconds (adjustable)

4) Transmission speed: 0~40m/min (adjustable)

5), the maximum suction depth: 600mm

6), the maximum loading load: 400KG

7), the number of unilateral upper arm: four arms.

8) The number of single-arm suction cups: three.

9), upper flip arm: double flip

10), loading station: single station

11), power supply/power Installation power supply: 380V/50HZ (special circumstances can be adjusted according to customer requirements)

12), installation power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14), vacuum pressure: -70~ -90Kpa (adjustable according to glass thickness)

2. Technical information:

2.1. Machine overview:

1) The automatic loading machine is an auxiliary equipment that extracts the original glass sheet from the material rack, turns it over to the water platform, and transports it to the cutting machine or other processing table.

2) The vacuum system adopts a well-known brand vacuum pump, which greatly improves the safety and stability of the whole system; the main body of the frame is driven by a motor to move on a double track, and the main frame arm is equipped with suction cup arms, each of which has three The suction cup is adjustable. The frame moves forward and the suction cup arm flips up at the same time. When the suction cup touches the original glass on the glass frame, the vacuum pump starts to work, and the suction cup generates a vacuum to suck the glass. When the vacuum degree reaches the set value, the flip arm lifts and flips to Horizontal position, after exhausting, the glass will be conveyed to the end of X axis and positioned, waiting to be conveyed to the cutting machine. The whole operation process is controlled by PLC.

2.2 Technical description

1) Flip mode: mechanical flip, fast running speed, stable operation, no jitter, and can meet the glass loading of 3~8mm. Equipped with double-track overturning transmission chain protection to ensure the safety and reliability of the overturning process,

2) Flip angle: 95~98 degrees adjustable. It can meet various angles of glass racks.

3) Suction depth: With special connecting rod telescopic mechanism, the suction cup can extend forward up to 150mm, which can meet the loading depth of 600mm. It can be loaded directly from the iron frame without any auxiliary frame.

4) Induction device: use two sets of glass photoelectric sensors (one set for use and one set for standby), which can effectively prevent safety accidents caused by induction failure. Equipment operation is more secure, stable and reliable.

5) Lifting device: The unique connecting rod lifting device can ensure that the lifting action is synchronous and consistent, and eliminates the defect of asynchronous lifting. Guaranteed safe slicing of glass.

6) Adsorption device: The suction cup adopts an advanced double-layer adsorption structure (two layers inside and outside), and the suction sheet is firmer, eliminating the defect of adsorption and air leakage caused by the scratching of the outer layer of the suction cup.

7) Suction cup control: Each suction cup has a separate air valve for on-off control, and the number of suction cups can be freely selected, which is convenient for the operation requirements of various sizes of glass.

8) Protection of wrong piece lifting: The unique lifting protection device of the equipment can effectively prevent the glass

breakage caused by the failure of the glass to be timely and wrong.

9) Alarm device: with automatic detection and traffic light alarm device, it can automatically alarm and display abnormal

conditions. Equipped with an emergency stop switch, which can be controlled in the event of an abnormality.

10) Operation mode: The device has two functions: automatic mode and manual mode. Easy and intuitive operation

11) Operation interface: It adopts color LCD touch screen display interface and Chinese and English display modules, which is convenient and quick to operate.

12) Parameter setting: The sequence of film loading and the number of films loaded at each station can be automatically set digitally, and it can be fully connected to the cutting machine. , more convenient and faster.

SY-4028 automatic cutting machine

Basic performance:

1. Equipment specifications:

★Maximum size of cutable glass: 4000*2800mm

★Workbench height: 900±30mm.

★Equipment weight: 2.5T.

★Cutting thickness: 2~10mm

2. Cutting parameters:

★ Linear parallelism: ≤±0.25mm/m

★ Diagonal line precision: ≤±0.35mm/m (the above precision is subject to the cutting line precision before breaking pieces)

★ Cutting bridge speed: 0~180m/min. (adjustable)

★ Cutting bridge acceleration ≥3.0m/s²

★ Tool head frame speed ≥180m/min

★ Tool head frame acceleration ≥6.0m/s²

★ Belt transmission speed ≥40m/min

★ Cutting head positioning accuracy error ≤±0.2 mm

3. Power/Power:

★ Installation power requirements: 380V/50HZ

★ The actual power of the equipment: 8KW.

★Compressed air: 0.6MPA.

4. Equipment performance

★Equipment frame: The equipment has undergone aging treatment to ensure that the table is not deformed and the parallelism is accurate.

★Cutting knife holder: the knife head can be rotated 360 degrees, up and down cutting (can accurately cut any straight line and various special-shaped glass)

★Mesa: Welded by steel plate. High flatness, not easy to deform. .

★Felt: Imported industrial felt (fiber and wool components) with good flatness, anti-static, and reduce glass scratches.

★ Oil supply method: Pneumatic automatic oil filling, synchronized with the lower knife.

★Conveying device: synchronous belt conveys automatically.

5. Mechanical part

★ Platen: steel plate. (flatness≤±0.20mm/m).

★Rack: Japan KHK.

★ Transmission belt/pulley: Barbery

★Cutter/Clamp: Tungsten steel with high penetration.

6. Electrical part

★Use the computer to control directly, the Microsoft Windows interface.

★Voltage: 380V/50HZ. Equipment with transformer.

★Motor: Japan Yaskawa servo motor.

★Proximity switch: Xinling Electric

★Control card: imported from the United States, Galil

★Main electrical components: Relay Chint.

★Pneumatic proportional valve: Japan SMC

7. Software

★Your friend (optional)

★The optimization software and the production management software can be used together.

★With the lower knife limit protection function.

★It can automatically calculate the production capacity function.

★With more than 2000 kinds of cutting gallery. (convenient for drawing and operation)

★Compatible with AUTO CAD drawing software.

★The optimization software is directly compatible with the cutting software.

★With automatic correction function. Ensure cutting accuracy.

★Cut path selection function. Ensure optimum cutting speed.

★Automatic adjustment of cutting knife pressure, fast, accurate and stable.

★Automatic pressure for special-shaped cutting, which can quickly and effectively ensure the cutting effect.

★Origin correction function. The origin can be set twice.

★ Operation input: keyboard and mouse. Chinese/English dialogue interface

★With special-shaped cutting knife pressure automatic adjustment function, to ensure the best cutting effect.

★Special-shaped template scanning: It has the function of converting various (including special-shaped) templates into CAD graphics after point-by-point scanning.

★Optimization software: It can sort the cutting size in any combination, output the best cutting plan, and improve the cutting rate. And it has the function of manual modification in the software after optimization. Effectively improve cutting utilization.

★Optimized pressure and speed: According to the pattern, straight line, arc, inner curve, outer curve starting point and end

point; automatic optimization and adjustment of acceleration section, deceleration section, etc. to output the most suitable pressure and speed.

★Shaped Gallery: Contains more than 300 kinds of special-shaped software gallery, this gallery can meet the needs of all

possibilities.

★Chinese operation interface: the man-machine dialogue should adopt the full Chinese menu.

★Drilling positioning function: The special-shaped library provides the drilling pre-positioning function.

★Protective function of cutter head: It has the function of mechanical protection to eliminate all possibility of collision.

★Special-shaped cutting: The equipment can accurately and automatically cut any straight line, oblique line or special-shaped.

★Belt conveying: The motor directly drives the belt to convey the cut glass to the peeling table.

★Stroke protection: The maximum stroke of the equipment has double protection of mechanical and electrical.

★Cutting pressure adjustment function: Any cutting pressure adjustment can be directly adjusted by the keyboard without manual operation.

Fully automatic horizontal breaking machine

Features

The machine adopts the rollers that ride across the cutting line on the top, and the ejector mechanism on the bottom. Both top and bottom are pneumatically controlled. According to the collected data signals, the cut glass is broken. The broken glass is transferred to the second section of the machine. After entering the second section completely, the lateral transfer rubber roller is lifted to transfer the glass to the longitudinal breaking machine.Changing product specifications requires manual adjustment of the positioning position.With edging system. Pneumatic control of the edger system. Minimum edge margin 15--20mm

Configuration:

Frame: GB square tube welding

PLC+touch screen Delta

Cylinder: AirTAC Adjustable Cylinder

Roller: Homemade POM Wheel

Transmission timing belt: Shanghai

Transfer roller: optical axis and polyurethane roller.

Program: self-designed

Processing parameters

Processing range:The maximum bearing original film is 3660*2440mm;

Product range: 300*300---500*500mm (different specifications, need to manually adjust the position of the positioning block)

Thickness: 2--5mm

Beat: about 10 seconds a piece.

Power: 3kW

Fully automatic vertical breaking machine

Features

The same as the horizontal breaking machine. Double channel discharge.

Configuration:

Frame: GB square tube welding

PLC+touch screen Shenzhen

Cylinder: domestic adjustable cylinder

Roller: Homemade POM Wheel

Transmission timing belt: Shanghai

Transfer roller: 30 optical axis and polyurethane roller.

Program: self-designed

Processing parameters

Processing range: 300*300---500*500mm

Beat: about 10 seconds for two pieces

Power: 3kW

SY-800-2 glass washing machine with air knife

Structure introduction:

* The equipment is 2-stage cleaning; the second-stage cleaning requires industrial grade pure water.

* work process:

Feeding section————The first section of water high pressure spray cleaning 2 pairs of brushes pre-cleaning——a pair of air knife cutting water——main cleaning + 3 pairs of hair brushes + 3 pairs of air knife air drying + oven drying—— discharge section

* General structure:

1 Feed end (800mm);

2 The second pre-cleaning section; the length is about 400mm; two pairs of brushes; the water tank is automatically replenished from the next water tank; independent water tank. A pair of air knives cut the water.

3 main cleaning sections; three pairs of brush cleaning; water temperature controllable;

4 Air-drying section: three pairs of air-knife air-drying; high-pressure air-knife + oven;

5 discharge section (600mm).

* Structural details:

* The national standard square tube frame; all stainless steel casings; the equipment is a segmented structure

* Each section has an independent water tray to achieve independent circulation of each section. and can be automatically supplemented from the back end to the front end

* Conveyor/roller: silicone rubber roller; stainless steel shaft head;

* This equipment is designed to be driven by dense rollers, with a large processing area, and the glass can be cleaned by

circulating water at one time. Roller spacing 120mm; minimum glass 300*300mm

The transmission mode is bevel gear transmission, which has the advantages of stable, durable and reliable structure

The drive is a variable frequency motor, controlled by PLC; one-button start, adjustable transmission speed

* Set various parameters directly on the touch screen.

* Each section of water inlet pipe is equipped with a T-type filter, which can filter fine particles; the second section has a

water heating system.

* Each water tank is equipped with a liquid level meter at the water inlet and outlet, which can automatically replenish and

drain water.

Basic parameters:

Glass size range 300*300—500*500mm;

* Water pump: 150w, 380v stainless steel self-priming pump

* Gear motor: 1.5kw, 380v Guangdong

* Weight: 1200KG

* Dimensions: 2800×1500×2200 (mm) (estimated)

* Equipment transmission roller height: 850 plus or minus 50mm

Glass cleaning range: 0.5—6.mm

* Cleaning speed: 0--6m/min

Water temperature range: room temperature - 45 degrees Celsius

basic configuration

* Water tank, cleaning and drying section cover: 304 stainless steel

* Brush: Dupont silk

* Transmission roller: optical axis + rubber sleeve or rubber roller

* Fan: 380V, 18KW high pressure fan

3-phase asynchronous motor: 1.5kw, 380v (variable frequency speed regulation) Guangdong

* Water pump: 150w, 380v stainless steel self-priming pump

* Gear motor: 1.1kw, 380v Guangdong

* Inverter: Delta

* PLC: Delta

* Touch screen: Delta

* Frame GB square tube

* Side plate stainless steel bending

* Cleaning section pole Cold-drawn plate electroplating hard wrap

* The upper platen in the cleaning section, aluminum finishing and oxidation

* Electrical parts: Chint

Equipment requirements for glass:

1 Water-based cutting fluid is required for cutting

2 The suction cup of the loader is a non-marking suction cup

3 No organic matter adhesion

Acceptance Criteria:

1 No visible pollution, impurities, water marks, scratches

2 No visible pollution, impurities, water marks, scratches under incandescent lamps;

3 The cleanliness meets the cleanliness required by hot bending; the pass rate is 99.9%

Company Profile

Anhui Ruilong glass machinery co.,ltd

Anhui Ruilong glass machinery co.,ltd focus on intelligent glass machinery and relevant automatic machinery . we are also one of the comprehensive new enterprises that provide the research and development、production、sale 、 technology service and After-sale maintenance and other services .The company covers an area of 40000㎡, total investment more than 200 million yuan(31 million dollar), existing staff 80 people.

So far Ruilong has been won the recognition award in Anhui province industrial design competition ,Bengbu city first sets of major technical equipment certification enterprise specialization, arts and new certification enterprises, Bengbu city Internet and information fusion development demonstration and many kinds of honorary certificate .

Our company research and development design 、production and sales of main products are: loading and uploading for all kinds of glass machine, CNC glass cutting machine 、Semi-automatic glass cutting machine, double or single sides glass grinding machine, various types of ultra-thin glass cutting machine and grinding machine, normal ,convex 、ultra-thin glass cleaning machine, glass rod、brick、tube、 bottle and optical material cutting machine, glass transmission table, glass drilling machine, Top level intelligent cold glass processing line and all kinds of non-standard automation equipment and etc .

Product packaging

Patent

FAQ

1. who are we?

We are based in Anhui, China, start from 2015,sell to Domestic Market(40.00%),Eastern Europe(20.00%),North America(10.00%),South Asia(10.00%),Mid East(10.00%),Oceania(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Glass cutting machine,CNC Automatic Glass Cutting Machine,Automatic glass edging grinding machine,Automatic glass washing machine,Glass deep-processing machine

4. why should you buy from us not from other suppliers?

RuilongWith advanced technology, production processes and business model. Have special r&d personnel, can develop new product independently. Our products are widely used in building glass, electric glass, optical glass, glass craft etc.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

We are based in Anhui, China, start from 2015,sell to Domestic Market(40.00%),Eastern Europe(20.00%),North America(10.00%),South Asia(10.00%),Mid East(10.00%),Oceania(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Glass cutting machine,CNC Automatic Glass Cutting Machine,Automatic glass edging grinding machine,Automatic glass washing machine,Glass deep-processing machine

4. why should you buy from us not from other suppliers?

RuilongWith advanced technology, production processes and business model. Have special r&d personnel, can develop new product independently. Our products are widely used in building glass, electric glass, optical glass, glass craft etc.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDU;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese