Теплоизоляционный материал хорошая цена огнеупорное растворимое керамическое

- Категория: Other Ceramic Fiber Products >>>

- Поставщик: Zibo,Jucos,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 893.2 $* | 938.19 $* |

| Aug-17-2025 | 885.8 $* | 929.57 $* |

| Jul-17-2025 | 743.46 $* | 780.53 $* |

| Jun-17-2025 | 870.21 $* | 914.92 $* |

| May-17-2025 | 758.73 $* | 796.47 $* |

| Apr-17-2025 | 855.30 $* | 898.93 $* |

| Mar-17-2025 | 848.10 $* | 890.48 $* |

| Feb-17-2025 | 840.82 $* | 882.77 $* |

| Jan-17-2025 | 833.68 $* | 875.55 $* |

Характеристики

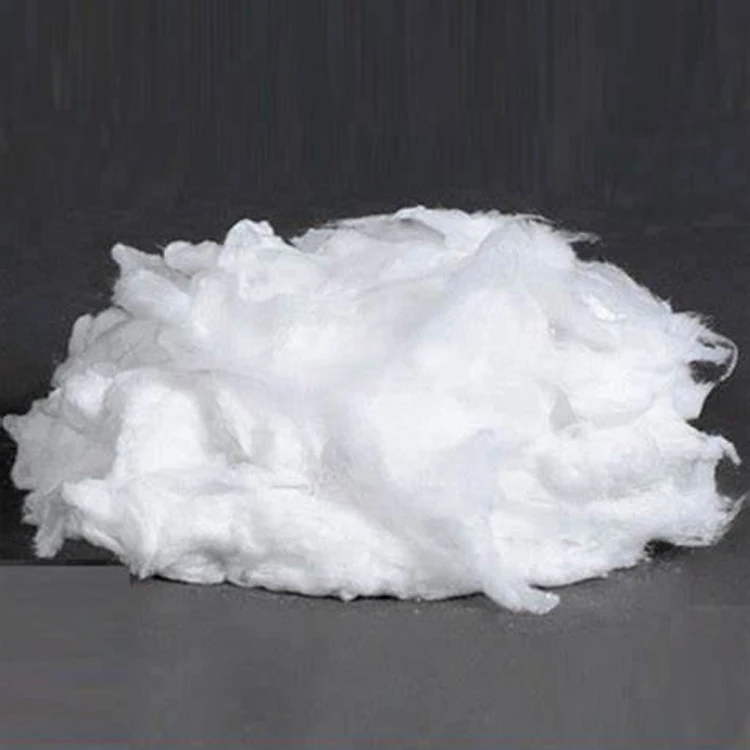

Thermal Insulation Material Wool Good Price Refractory Ceramic Fiber Bulk

As the crucial and staple materials for producing ceramic fiber blanket, board, module and other formed products, ceramic bulk fiber is normally manufactured from high purity raw materials-alumina powder, silica sand through unique production techniques of spun or blowing, these bulks are loose, long and flexible with fine thermal properties, at present, the chopped fibers are vacuum formed production, the lubricated bulk fibers are the fiber for textiles are all available. Ceramic bulk fibers Serve as ab ideal filler for various types of refractory lining and insulation tools.

Features Of Thermal Insulation Ceramic Fiber Bulk

Good springiness for fiber

Excellent strength and resistance to blowing

Excellent chemical stability, resistance to erosion

Low thermal conductivity

Low thermal shrinkage

Excellent sound absorption

Applications Of Thermal Insulation Ceramic Fiber Bulk

Filling insulation and joint sealing

Back-up lining for industrial furnaces

Fireproof materials for construction

High temperature materials for filtration

Raw materials of fiber Paper and vacuum forming products

Raw materials of fiber coating materials

Raw materials of fiber castable and coatings

High-temperature furnace heating equipment wall lining fillings

Raw materials of fiber textile products

Specifications Of Thermal Insulation Ceramic Fiber Bulk

- Alumina contents range from 34% to 44%

- Widely used throughout metallurgical industry

Physical And Chemical Indicators For Thermal Insulation Ceramic Fiber Bulk

STD BULK | HP BULK | HZ BULK | ||

(%) Chemical Composition | Al2O3 | ≥44 | ≥45 | ≥34 |

SiO2 | ≥52 | ≥54 | ≥50 | |

Fe2O3 | ≤1.0 | ≤0.5 | ≤0.5 | |

Na2O | ≤1.0 | ≤0.2 | ≤0.2 | |

ZrO2 | - | - | ≥15 | |

Specification Temp. (℃)

| 1260 | 1260 | 1430 | |

Shot content (%) | ≤15 | ≤15 | ≤12 | |

Fiber Diameter(μm) | 3.5 | |||

Pictures Of Thermal Insulation Ceramic Fiber Bulk

As the crucial and staple materials for producing ceramic fiber blanket,board,module and other formed products,ceramic fiber bulk is normally manufactured from high purity raw materials-alumina powder,silica sand through unique production techniques of spun or blowing,these bulks are loose,long and flexible with fine thermal properties,at present,the chopped fibers are vacuum formed production,the lubricated bulk fibers are the fiber for textiles are all available.Cotton Stuffing Fiber serve as ideal filler for various types of refractory lining and insulation tools.

Specification

Packaging & Shipping

25kg woven bag or carton package,as customer request

Company Information

JUCOS REFRACTORY was created in 2008 with combination of global expertise and local knowledge, aim to supplying range of refractory products, services and solutions to the global Iron, Steel, Non-Ferrous, Cement, Glass, Incinerator, Energy, Petrochemical and other Chemical Industries.

Ceramic fiber bulk

JUCOS REFRACTORY located in Shandong Zibo, the place where rich in refractory raw material, we exploiting the availability of rich & high pure natural mineral resources of China understands the exact intelligence of the customers worldwide to design, and offer, manufacture and market high quality & performance oriented refractory products with a team of Techno Creative Commercial Engineers.

As an integral part of our system, we anticipate customer’s timely requirements and personalize our service so that each of our customers are rest assured with the fact that all products are tested at each of our production and development stages handled by capable and committed technicians working round the clock with a range of production capacity up to 60,000 Mt / Year shaped refractory and 20,000 Mt / Year unshaped refractory plant, well equipped with all sophisticated & essential production, infrastructure and in house research and development facilities. Our product range includes High alumina Bricks, Clay brick, Insulation brick, Magnesia Carbon Bricks, Magnesia Chrome Bricks, Magnetite Bricks, Insulation fiber blanket, board, paper, rope, Monolithic refractories in the application zones of Steel and Iron furnace, Non-Ferrous furnace, Cement Rotary Kilns, Glass Furnaces, Lead Rotary Kilns, Copper Converters and so on.

1.How can you control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What is your lead time?

It usually needs about 15- 20 days after receiving the PO.

3. Do you provide free samples?

Yes, free samples are available, generlly speaking, the buyer shall bear all the delivery cost.

4. What is your payments terms?

We can accept 30% deposit, 70% balance to be against the BL copy or by LC, or other payment terms.

5.Can we visit your company?

Yes, for sure, you are welcome to visit our company.

6. What standards do you have?

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.