Независимая инспекционная компания проверка завода

- Категория: Certification, Inspection & Credit Management >>>

- Поставщик: Qingdao,Pinji,Inspection,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 176.48 $* | 185.77 $* |

| Aug-17-2025 | 175.24 $* | 184.40 $* |

| Jul-17-2025 | 147.73 $* | 154.44 $* |

| Jun-17-2025 | 172.67 $* | 181.86 $* |

| May-17-2025 | 149.49 $* | 156.36 $* |

| Apr-17-2025 | 169.78 $* | 177.27 $* |

| Mar-17-2025 | 167.2 $* | 175.77 $* |

| Feb-17-2025 | 166.95 $* | 174.99 $* |

| Jan-17-2025 | 164.19 $* | 172.90 $* |

Характеристики

General Certificate of Conformity (GCC) |

Manufacturers and importers of certain general use products (i.e., non-children’s products) for which consumer product safety rules apply, must certify, in a written General Certificate of Conformity (GCC) based on testing or a reasonable testing program, that their products comply with those applicable rules. Below on this page, CPSC provides two samples of GCCs for fictitious products, showing example layouts of the GCC's required elements; one for adult clothing and one for mattresses. These samples are illustrative and do not capture every possible consumer product safety rule that may apply to a consumer product. The GCC and supporting test reports must be in English.

- The list of non-children's (general use) products requiring a certificate is found here.

- See our frequently asked questions (FAQs) about GCCs.

(Note: All manufacturers and importers of children’s products are subject to different testing and certification requirements. Learn more here.)

Elements Required in a GCC

- Identification of the product covered by this certificate:

- Describe the product(s) covered by this certification in enough detail to match the certificate to each product it covers and no others.

- Citation to each consumer product safety regulation to which this product is being certified:

- The certificate must identify separately each consumer product safety rule administered by the Commission that is applicable to the product.

- Identification of the importer or domestic manufacturer certifying compliance of the product:

- Provide the name, full mailing address, and telephone number of the importer or U.S. domestic manufacturer certifying the product.

- Contact information for the individual maintaining records of test results:

- Provide the name, full mailing address, e-mail address, and telephone number of the person maintaining test records in support of the certification.

- Date and place where this product was manufactured:

- For the date(s) when the product was manufactured, provide at least the month and year. For the place of manufacture provide at least the city (or administrative region) and country where the product was manufactured or finally assembled. If the same manufacturer operates more than one location in the same city, provide the street address of the factory.

- Provide the date(s) and place when the product was tested for compliance with the consumer product safety rule(s) cited above:

- Provide the location(s) of the testing and the date(s) of the test(s) or test report(s) on which certification is being based.

- Identification of any third party laboratory on whose testing the certificate depends:

- Generally, this section should be labeled “N/A” for a GCC because third party laboratory testing is not a requirement for non-children’s products. (It is only a requirement for children’s products and must be included in a CPC.) However, if a certifier voluntarily uses test results from a third party laboratory as the basis for issuing its GCC, the law requires that the certifier must then provide the name, full mailing address, and telephone number of the third party laboratory.

Final Random Inspection (FRI)

FRI takes place when the merchandise is 100% completed and at least 80% are well packed, marked and ready for shipment. Our inspectors randomly draw some samples from finished goods, based on statistical random sampling technique, commonly known as ANSI/ASQ Z1.4, MIL-STD-105E, BS6001, DIN40080, ISO2859 OR NFX06- 022, to verify that the finished shipping lots conform to your specifications. In general Qty check Style, color & material Visual check(workmanship) Function,safety check

We would like to suggest client to booking this inspection at least 3 days before loading so that if some quality problems were found by Pinji inspector, clients will still have time to ask factory to re-work.

Single Sampling Plan

AQL Table

Pre-production Inspection (PPI) A visual check on the quality of components, materials, and accessories at the beginning of production against clients' specifications and/or reference sample. The PPI thus permits timely corrections and improvements before the mass cargo will be manufactured, any non-conformity is immediately reported so as to avoid delay in shipment. In general, we will check the following aspects for PPI:

Evaluate the production capability and equipments in the factory .

Check factory of quality control ability and executive status.

Check the accuracy of production facilities and equipments.

Audit production techniques and make sure the reasonable layout of factory QC person,

Check the qty and quality of raw materials and main components that will be used in your products, foreseeing any possible problems to avoid them, verifying that your products spec are being met early .

During Production Inspection (DPI)

A visual check on the quality of components, materials, semi-finished products when at least 10%-20% of the order has been completed. Unique randomly inspects the production batch and those products in the line for possible defects, if any should occur, we identifies the deviation and provides advice on the corrective measures that are necessary to ensure a uniform batch quality product. In general:

Evaluate the production status during the manufacturing process

Randomly inspect the finished samples on-site and compare them with your product spec

According to the evaluated status of finished and semi- finished samples, rearrange the QC layout in the facto

Evaluate the packing details and packing material

Check the accuracy of production equipments and disposal methods for defective goods

100% inspection (Full Inspection)

When the merchandise is 100% completed, we will check the quality of goods unit by unit, which covers product description, style & color, workmanship, quality, function, label, package, size measurement if available etc, to make sure 100% of the goods meet your specified quality requirement. Note: for those products of high value or complicated internal structure, we suggest to take full inspection.

Container Loading Supervision (CLS)

Before loading, our inspector will check products' information, qty, package, during the course of loading, our inspectors will keep closely look at the loading process, ensure that the export cartons are well arranged in the container with no risks of deformation, collapse, help manufacturer finish loading under correct and clear working clauses and working process. In general: Record the weather/arrival time of container/No./truck No Check the inner/outer condition to see if there is any damage/wet/hole/peculiar smell Check the qty of goods loaded and record the condition of outer packaging(master cartons/pallets) Randomly draw and open some cartons to verify that the goods meet with clients' specification Supervise the whole loading process Seal the container with the custom's seal and unique quality inspection's seal Record the seal No. and departure time of container.

Random Inspection

(Pre-production Random Inspection, During Production Random Inspection, Pre-shipment Random Inspection) As per customer's quality requirement, we will sample the products according to international MIL-STD-105E(AQL) or other standards to inspect the packing, appearance, color, size, function, safety, etc.

Purpose of Pre-production Random Inspection: To help know the production status & raw material quality and avoid any mistake on quality standard, order quantity and make sure that the order is arranged;

Purpose of During Production Random Inspection: To help know the production status & product quality during production and avoid any mass quality problem & abnormal production situation;

Purpose of Pre-shipment Random Inspection: To know the finished products quality & quantity and avoid any mass quality problem & shortage shipment.

Prefessional

In business consulting, quality management and inspection services.we can advise you regarding suppliers' selection, help you to make the factory audit and assessment and provide third party inspection services all along the production process.

Extensive

QC experience and strong detection capability to provide the buyer with the most reliable product quality guarantee. Our inspectors are trained to detect products containing non-standard or non-compliant components.

Responsible

We respect the fact to be impartial, fair and honest. Inspection independent from the manufacturer. PJ Inspection guarantees independence, fairness and trustworthiness for whole inspection procedure. We are responsible for our clients only.

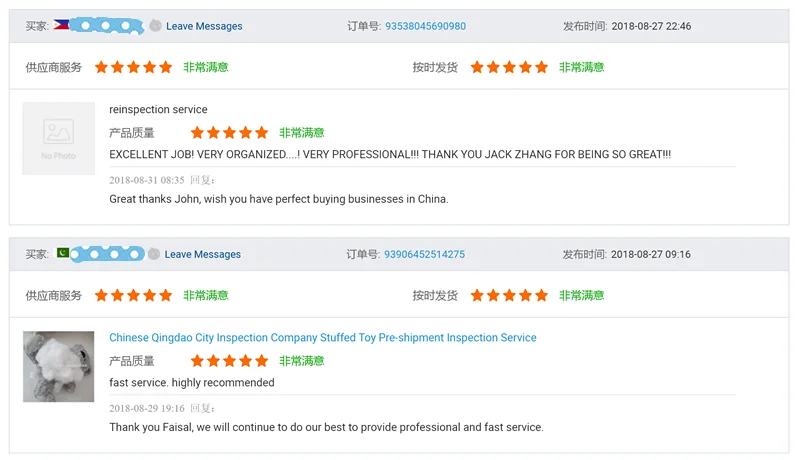

Best Comments

1, Book an Service 2-3 days in advance.

Contact Number

Contact Number

2, Pay us the cost before services.

3, Start inspection/audit/testing jobs on the booked date.

4, Issue the reports within 24 hours after inspection.

5, Continuing Services after inspection.

| Question 1:* How many pcs will you choose for inspection ? |

| Answer: Normally we select sample base on AQL standard,however we can talk about it if you need special sample quantity before inspection. |

| Question 2 :* When will you send final report ? |

| Answer: Normally the second day, if it's urgent for you, we can make within the same day. |

| Question 3:* Is there any hiden charges? |

| Answer: No, the price is all included. |

| Question 4:Can we get solution if there is problem with inspection ? |

| Answer: Of course, we will continue services after inspection, we can also provide suggestions for your reference incase the inspection failed. |