Лидер продаж автоматическая машина для изготовления кирпичей с гидравлическим давлением и блокировкой грунта 2024 по

- Категория: Brick Making Machinery >>>

- Поставщик: Contrust,Machinery,Co.,Ltd.Contrust,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 9520.11 $* | 9996.64 $* |

| Aug-16-2025 | 9440.37 $* | 9912.55 $* |

| Jul-16-2025 | 7920.98 $* | 8316.26 $* |

| Jun-16-2025 | 9280.40 $* | 9744.21 $* |

| May-16-2025 | 8080.21 $* | 8484.91 $* |

| Apr-16-2025 | 9120.20 $* | 9576.0 $* |

| Mar-16-2025 | 9040.21 $* | 9492.73 $* |

| Feb-16-2025 | 8960.38 $* | 9408.25 $* |

| Jan-16-2025 | 8880.93 $* | 9324.81 $* |

Характеристики

Product Description

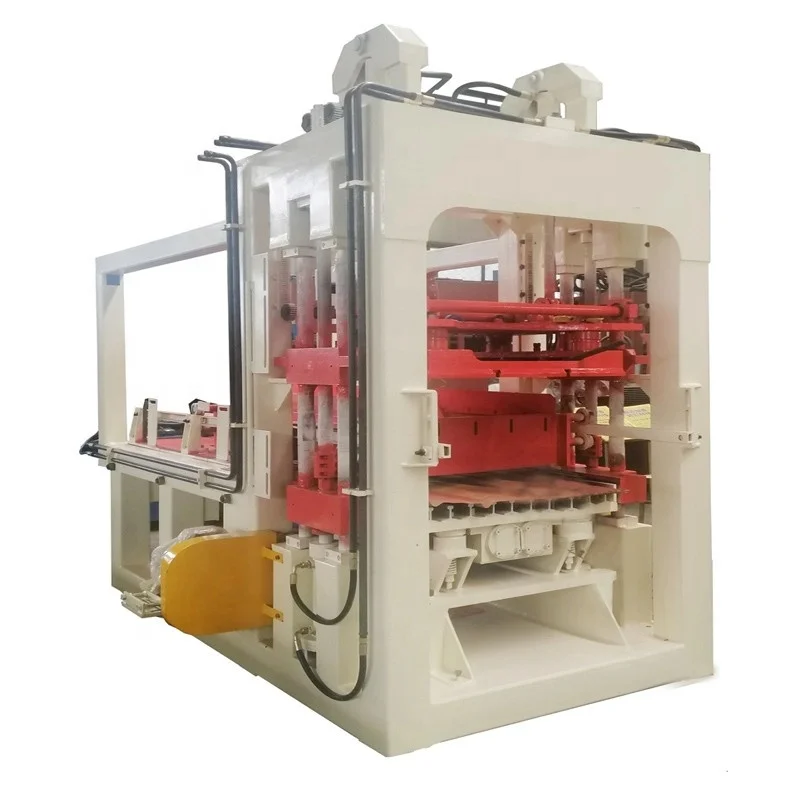

This is a kind of automatic brick making machine, adopts flat vibration, mold vibration, and squeeze compression vibration, manufactures the blocks with average density and high strength. And the unique dose charging device and the strong material-distributing structure ensure the block's quality of various materials. It adopts PLC control, and realizes the automatic plate-supplying, material-distributing, and brick-discharging. With the high efficiency, it is the ideal equipment to manufacture the new style wall material.

The block manufacturing process has five general phases:

1) Collection of raw materials

This involves looking for the main ingredients that will make the blocks, sand, cement, clay, fly ash, and other materials

2) Weighing and batching

Once the crucial raw materials, they undergo weighing so that they can meet the required weight before batching. They can be stored in cement silos, stationary, or mobile batching plant.

3) Feeding and mixing

the brick making plant starts making blocks from this stage. The materials – raw materials, water, and adhesive – are transported to the mixer. Once fed into the mixer, mixes the ingredients uniformly. This is to ensure they are of high density and quality.

4) Mixing unit to mold block

The mixture is then transported to the hopper using a conveyer belt. Once in the hopper, it finds its way to the mold block where through a combination of vibration and hydraulic pressure, compact and high-quality bricks are made.

5) Storage

The bricks laying on the pallets are transported to a storage area by manual carts.

Specification

QT4 -15 block making machine theoretical production capacity

Size(L*W*H) | Brick shape | Pcs/Mould | Pcs/hour | Pcs/8hours |

400*200*200mm | hollow brick | 4 | 720-960 | 5760-7680 |

240*115*90mm | hollow brick | 12 | 2160-2880 | 17280-23040 |

230*110*70mm | solid brick | 26 | 4680-6240 | 37440-49920 |

200*100*60mm | color brick | 16 | 2880 | 23040 |

200*163*60mm | interlock brick | 12 | 2160 | 17280 |

Application

This involves looking for the main ingredients that will make the blocks. Companies collect sand, cement, clay, fly ash, and other materials. For example, while the clay is extracted from the ground, fly ash is collected from power plants that use coal to generate electricity since it is a by-product of burnt pulverized coal. On the other hand, companies can get cement from local suppliers.

You can get different types of blocks depending on the raw material used and the shape. Hollow bricks, Paving bricks, Interlocking bricks, Solid bricks, Porous bricks.

Details Images

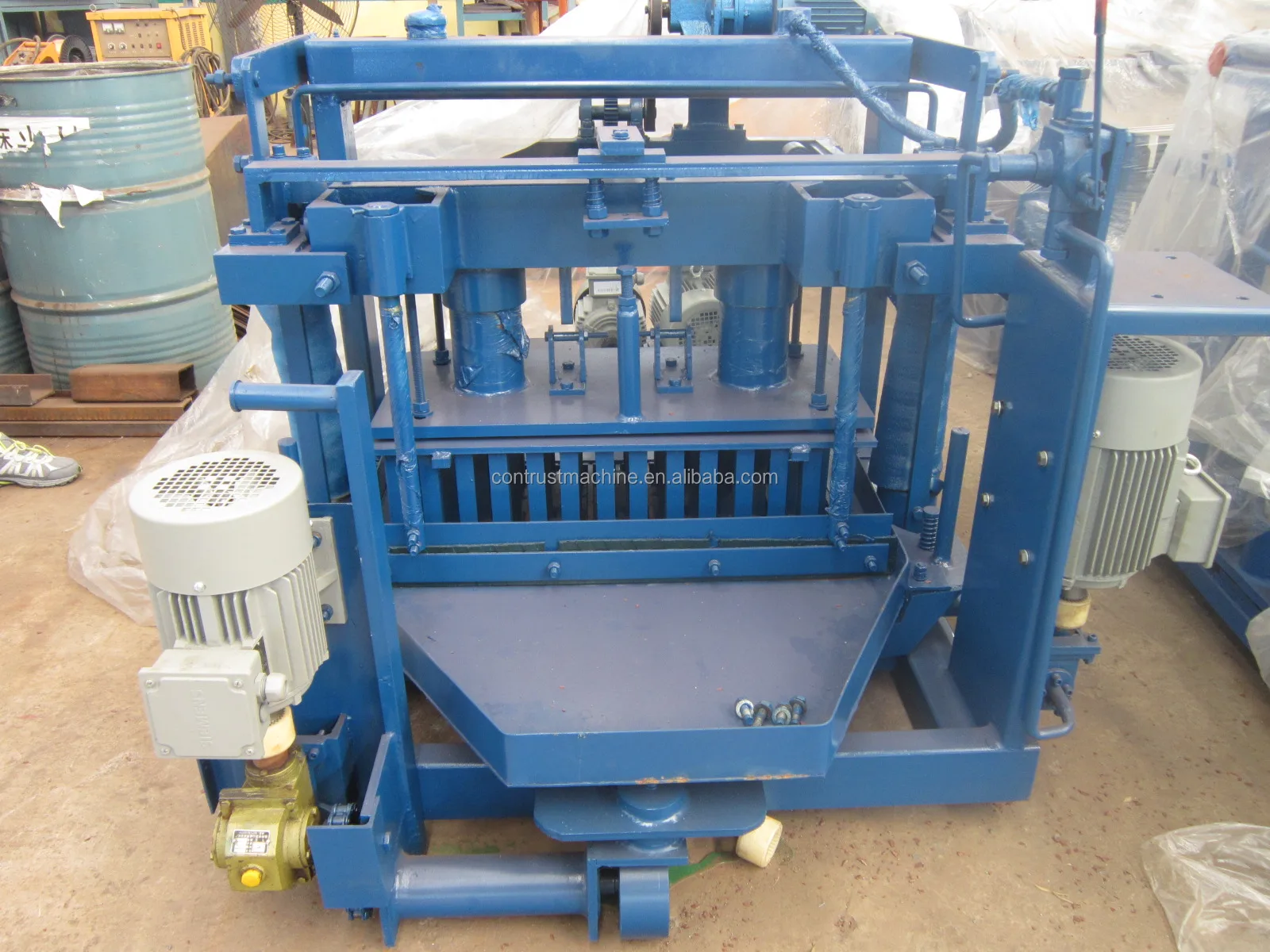

Main brick making machine

Siemens PLC

Control the operation of the brick making machine: feeding, shaking, pressing, sending and other operating instructions.

International brand, long service life, basically not damaged.

PLC control system and electrical components are imported components, including delta, Siemens and Schneider.

Mould

Wire cutting technology can ensure that the size of the mold is more accurate.

The carburizing treatment technology changes the molecular structure of steel.

Motor

Hydraulic station

Guard net

Enlarge the vibrating box

Attached with good brand vibration motors.

Fast start, high frequency, strong vibration force, make good brick quality.

Fast start, high frequency, strong vibration force, make good brick quality.

Company Profile

FAQ

● What shape of brick can be made?

-- The mold of brick machine can be changed, we will send pictures to you for confirmation, to match you with the right mold. For example, there are hollow brick, solid brick, pavement road surface brick, Interlocking bricks, porous bricks, colorful brick...

● What about the Minimum Quality Order?

-- The MOQ is 1 set. If you order large amount, you will get discount.

● What is the payment terms?

-- T/T, L/C, Western Union,credit card.

● Which kind of shipment do you support?

-- Sea transportation, air transportation and international express.

● When will you deliver the machine?

-- 7-15 workdays after receiving the deposit payment.

● Do you supply training and after-sale service?

-- Yes, we will supply installation and training on site or online. Also we have a professional service team that can solve problems as fast as possible.

● What about the warranty time of machine?

-- 12 months after shipment or 2000 working hours.

-- The mold of brick machine can be changed, we will send pictures to you for confirmation, to match you with the right mold. For example, there are hollow brick, solid brick, pavement road surface brick, Interlocking bricks, porous bricks, colorful brick...

● What about the Minimum Quality Order?

-- The MOQ is 1 set. If you order large amount, you will get discount.

● What is the payment terms?

-- T/T, L/C, Western Union,credit card.

● Which kind of shipment do you support?

-- Sea transportation, air transportation and international express.

● When will you deliver the machine?

-- 7-15 workdays after receiving the deposit payment.

● Do you supply training and after-sale service?

-- Yes, we will supply installation and training on site or online. Also we have a professional service team that can solve problems as fast as possible.

● What about the warranty time of machine?

-- 12 months after shipment or 2000 working hours.

Recommend Products

Contact Us