Yizumi 260 машина для литья под давлением пластиковая UN260SKII-V-PET литьевых

- Категория: Injection Molding Machines >>>

- Поставщик: Guangdong,Yizumi,Precision,Injection,Molding,and,Die,Casting,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.63 $* | 0.80 $* |

| Aug-20-2025 | 0.0 $* | 0.96 $* |

| Jul-20-2025 | 0.99 $* | 0.90 $* |

| Jun-20-2025 | 0.53 $* | 0.49 $* |

| May-20-2025 | 0.89 $* | 0.71 $* |

| Apr-20-2025 | 0.57 $* | 0.74 $* |

| Mar-20-2025 | 0.87 $* | 0.47 $* |

| Feb-20-2025 | 0.42 $* | 0.47 $* |

| Jan-20-2025 | 0.57 $* | 0.79 $* |

Характеристики

Products Description

Specification

DESCRIPTION | UNIT | DATA | |

Injection unit | Shot volume | cm3 | 1202.2 |

Shot weight (PS) | g | 1406.5 | |

oz | 49.6 | ||

Screw diameter | mm | 76 | |

Injection pressure | Mpa | 105.5 | |

Screw L:D ratio | 24:1 | ||

Max. injection speed | mm/s | 89 | |

Plasticizing Capacity (PET) | g/s | 70 | |

Screw stroke | mm | 265 | |

Screw speed(stepless) | r/min | 0-91 | |

Clamping unit | Clamping force | kN | 2600 |

Opening stroke | mm | 530 | |

Space between bars | mm*mm | 570x570 | |

Max. Daylight | mm | 1140 | |

Mold thickness(Min.Max) | mm | 195-610 | |

Ejector stroke | mm | 180 | |

Ejector number | 13 | ||

Ejector force | kN | 124 | |

Power unit | Hydraulic system pressure | Mpa | 17.5 |

Pump Motor | kw | 30 | |

Heating capacity | kw | 31.2 | |

Number of temp control zones | 6 | ||

General unit | Oil tank capacity | L | 360 |

Machine dimensions(LxWxH) | m*m*m | 6.66x1.59x1.96 | |

Machine weight | kg | 8400 |

NOTE: The listed machine price is for standard machine only, any extra requirement (e.g. CE/UL/KCS safety standard and so on) will be subject to extra charge.

Customized Pet Plasticizing Components

Preforms for cosmetic products

Bearing in mind the characteristics of the cosmetics industry, we have developed the special high-performance color mixing screw for PET colour preforms with a L/D ratio of 24:1. For PET materials such as iridescent and opalescent powders, it effectively improves the quality of color mixing and stability of products and ensures the

surface color uniformity after blow molding.

Bearing in mind the characteristics of the cosmetics industry, we have developed the special high-performance color mixing screw for PET colour preforms with a L/D ratio of 24:1. For PET materials such as iridescent and opalescent powders, it effectively improves the quality of color mixing and stability of products and ensures the

surface color uniformity after blow molding.

Water and oil preforms

A special PET high-speed screw for water and oil preforms designed according to the characteristics of ordinary water bottle and oil bottle industries provides a L/D ratio of 24:1 and achieves a high-speed and high-quality plasticizing under low shear conditions. It increases the plasticizing efficiency by nearly 100% compared with standard injection molding machines and boosts the original PET capacity by more than 30%.

A special PET high-speed screw for water and oil preforms designed according to the characteristics of ordinary water bottle and oil bottle industries provides a L/D ratio of 24:1 and achieves a high-speed and high-quality plasticizing under low shear conditions. It increases the plasticizing efficiency by nearly 100% compared with standard injection molding machines and boosts the original PET capacity by more than 30%.

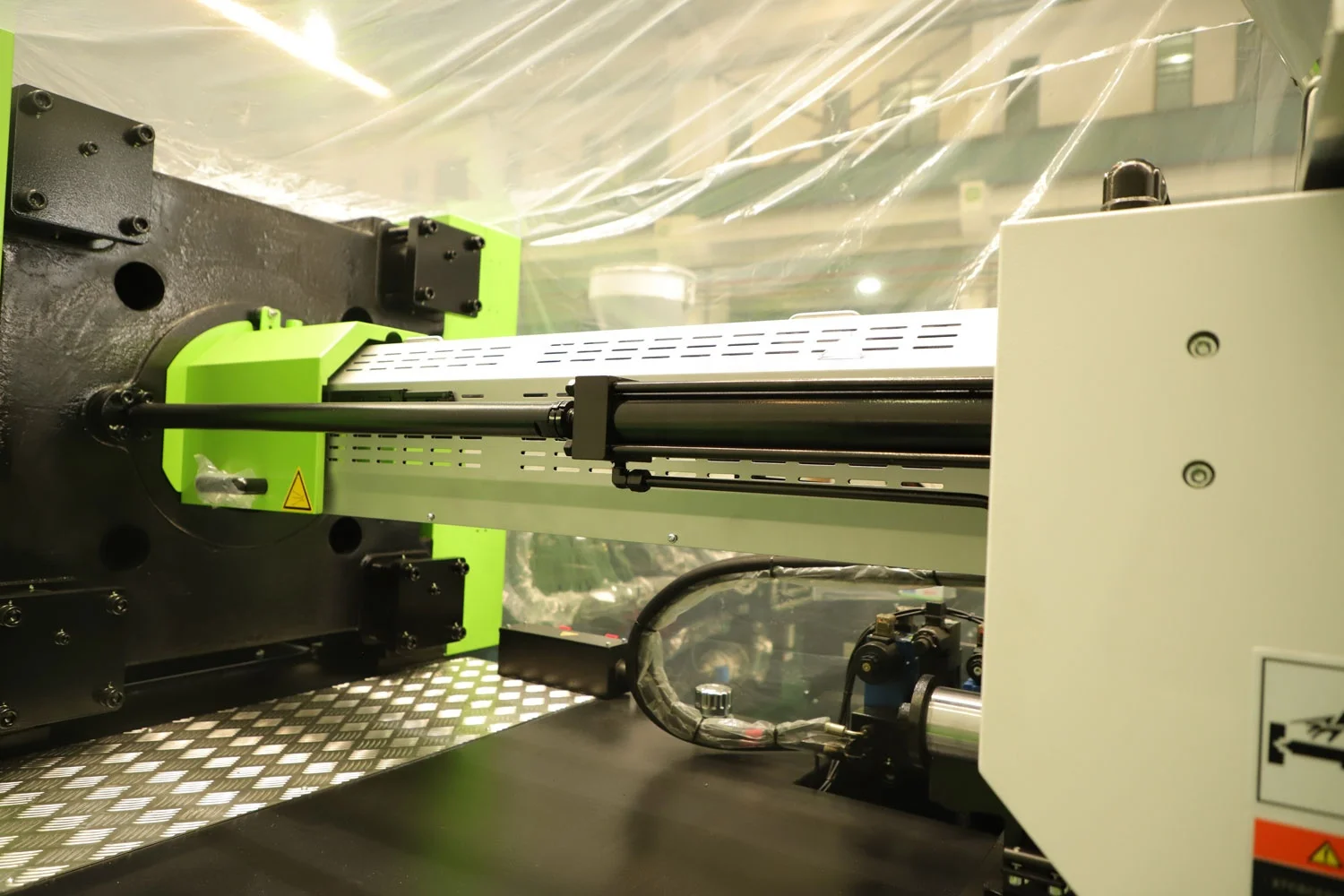

Optimized Injection Unit

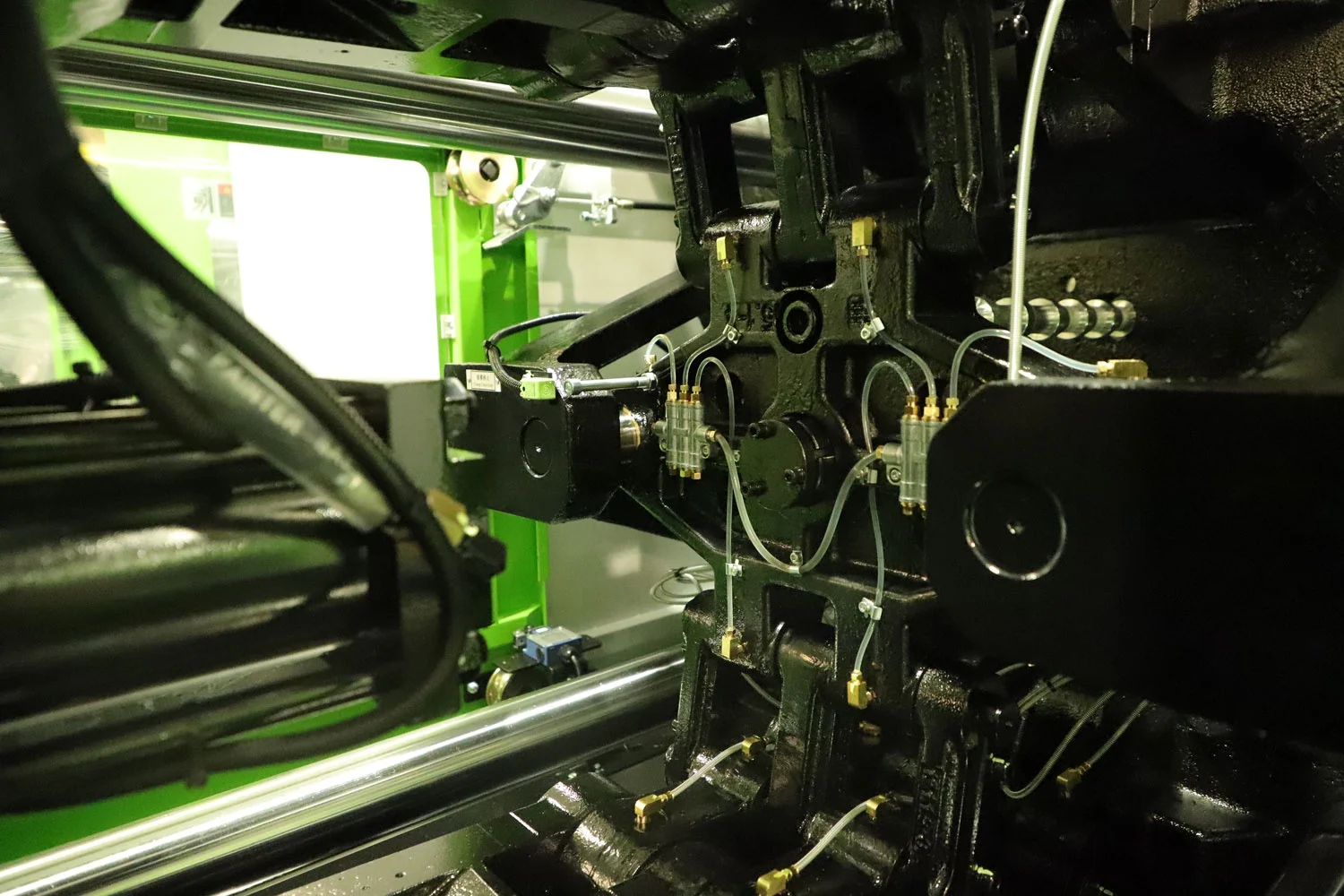

Using a double carriage design and one-piece carriage

support for models with multi-cavity molds. The optimized

injection mechanism applies force on the injection unit evenly and provides improved injection rigidity .

support for models with multi-cavity molds. The optimized

injection mechanism applies force on the injection unit evenly and provides improved injection rigidity .

Customized Shot Weight

Depending on the needs of current and future products and the suitable types of products and molds for each model, the machine can be customized with different injection weight options to meet requirements on product weight. High-performance Plasticizing System

Custom made enlarged plasticizing motor with enhanced motor displacement to ensure the service life of motor and stability of products. The synchronous plasticizing (electrical plasticizing) is available among other options. Compared to the standard PET injection molding machines, the production efficiency can be increased by more than 10%.

Platen With T-slot + Mold Clamp Hole Combination

The platen uses T-slot + mold clamp hole combination in

the horizontal direction and mold clamp holes in the

vertical direction to facilitate the mold loading and

unloading and enhance the overall rigidity of the platen.

the horizontal direction and mold clamp holes in the

vertical direction to facilitate the mold loading and

unloading and enhance the overall rigidity of the platen.

Main Configuration

User Friendly Design

Standard robot mounting holes to facilitate an easy and

fast installation. Mold needle valve control function is

available as options to effective reduce the internal

stress of product and improve the production yield.

fast installation. Mold needle valve control function is

available as options to effective reduce the internal

stress of product and improve the production yield.

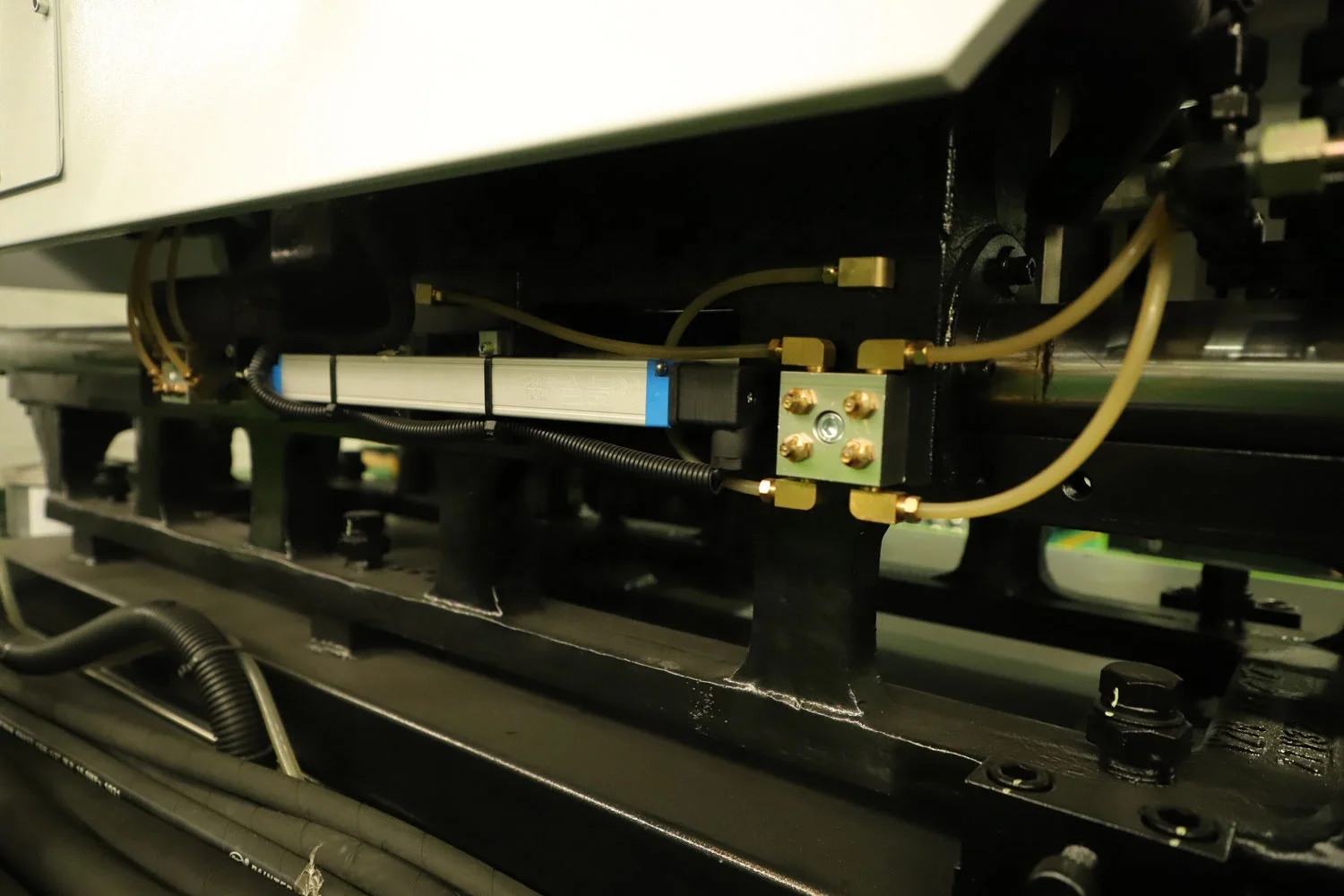

Optimized Cooling Water Transmitting Device

Enlarged cooling water transmitting device to ensure

the transparency of PET products.

the transparency of PET products.

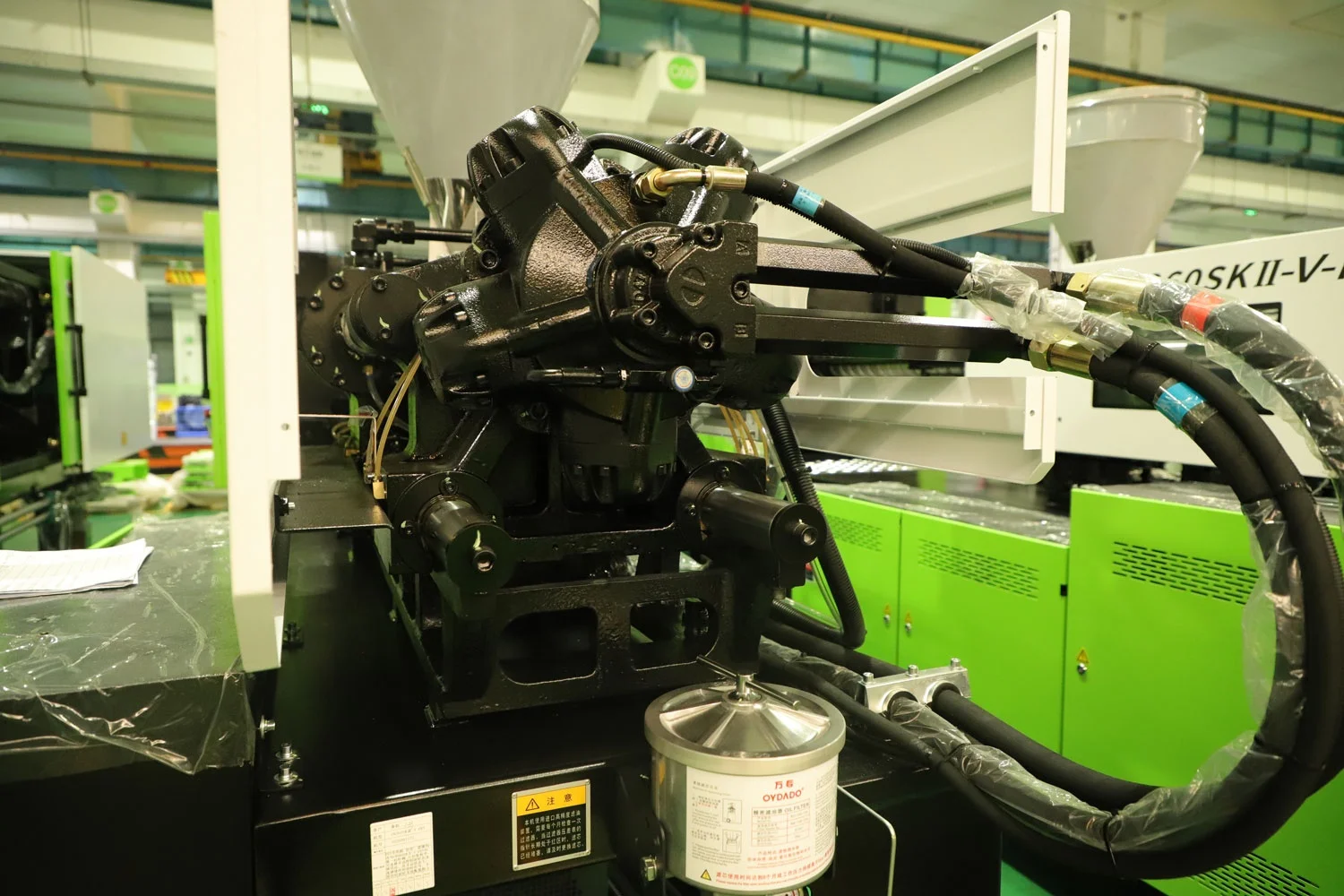

Enlarged Motor and Pump

By increasing the power of motor and pump, achieve

higher productivity with a speed 20% faster than

conventional machines.

higher productivity with a speed 20% faster than

conventional machines.

Optimized Cooling Effect

Larger cooler and oil tank capacity effectively lower the

oil temperature and improve the cooling effect.

oil temperature and improve the cooling effect.

Yizumi-made PET Preform Mold

16 cavities

32 cavities

48 cavities

72 cavities

Mold Parts

Product details

Production Process

Company Profile

Packing & Delivery

Why Choose Us

Exhibition

Certifications

FAQ

Q1: Where is your factory located?

A1: Guangdong Yizumi Precision Injection Molding and Die Casting Technology Co., Ltd which is located at No.12, Shunchang Road,Daliang, Shunde, Foshan, Guangdong Province, China 528306

Q2: Are you an integrated supplier for injection molding machine, mold, robot and auxiliary?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Yizumi has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, mold and auxiliary selection but also water .electrical, machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also. Currently we provide visit online by video call for the COVID-19.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 1-2 month.

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Mold trial will be available in Yizumi factory ?

A8: Yes, Customer can send the mold to Yizumi factory and test.

Q9 . Do you provide any spare parts with machine?

A9: Yes, Yizumi will provide one set standard spare parts to customer including heater ,filter, screw head ,screw washer, checking ring ,sealings, etc.

A1: Guangdong Yizumi Precision Injection Molding and Die Casting Technology Co., Ltd which is located at No.12, Shunchang Road,Daliang, Shunde, Foshan, Guangdong Province, China 528306

Q2: Are you an integrated supplier for injection molding machine, mold, robot and auxiliary?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Yizumi has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, mold and auxiliary selection but also water .electrical, machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also. Currently we provide visit online by video call for the COVID-19.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 1-2 month.

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Mold trial will be available in Yizumi factory ?

A8: Yes, Customer can send the mold to Yizumi factory and test.

Q9 . Do you provide any spare parts with machine?

A9: Yes, Yizumi will provide one set standard spare parts to customer including heater ,filter, screw head ,screw washer, checking ring ,sealings, etc.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.