Индивидуальный размер сильный N50 N52 магнит 5X5 Иман Neodimio 5X3 неодимовые магниты

- Категория: Magnetic Materials >>>

- Поставщик: Jintong,Flnorescent,Magnetized,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.43 $* | 0.31 $* |

| Aug-19-2025 | 0.31 $* | 0.44 $* |

| Jul-19-2025 | 0.10 $* | 0.64 $* |

| Jun-19-2025 | 0.56 $* | 0.42 $* |

| May-19-2025 | 0.94 $* | 0.34 $* |

| Apr-19-2025 | 0.25 $* | 0.18 $* |

| Mar-19-2025 | 0.68 $* | 0.77 $* |

| Feb-19-2025 | 0.50 $* | 0.42 $* |

| Jan-19-2025 | 0.22 $* | 0.68 $* |

Характеристики

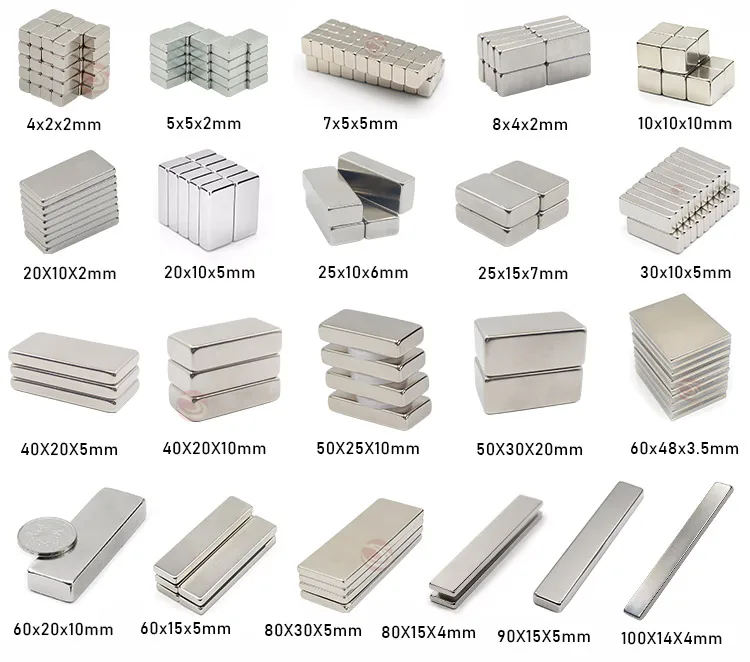

Product Example: ( Non Standard Item, Kindly send us dimension )

What style and size do you like??? You can tell us what you need. We can customize the magnet for you.

Click here to contact us and ask for better price with discounted shipping! ! ! >>

Here are some of our customers' customized magnets for reference

Magnet Applications: (widely used)

1. Electronic areas: speakers, headphones, acoustics, sensors and so on.

2. Motor areas: generators, servo motors, micro-motors, vibration motors, elevator motor and so on.

3. Clean Tech Energy: Water flow enhancement, wind turbines and so on.

4. Health care: MRI, medical treatment equipment and so on.

5. Other industries: electric doors and windows, electric vehicle, electric bicycles, computer, phone, boxes, magnetic tools, notebook and so on

1. Size Tolerance: (+/-0.05mm)

In production, we will keep standard tolerence +/-0.05mm. NOT send you smaller , for example if 20mm in size, we will NOT send you 18.5mm . To be frank, you can not see the difference by eyes.

3. Surface Treatment:

Q: Do neodymium magnets require surface treatments?

A: Yes. If magnets are without surface coating (also named plating), it may rust easily under humid conditions.

There have many plating options like Ni-Cu-Ni, Nickel, Zinc, Gold, Black Epoxy, White Epoxy coating and so on.

Zn and Ni-Cu-Ni coating are the most popular coating. The magnet with plating will resist the corrosion effectively.

4. Magnetization Direction:

5. Product Package:

Magnets are a special delivery product, which must be specially packaged before transportation to ensure that the products are well packed and that it can withstand the manhandling of shipping carriers.

WORLD -WIDE CUSTOMERS COMMENTS & FEEDBACK

Here is some of comments from our world-wide customers.

You can also check all the comments at our company profile.

[ TRUST YOU WILL LIKE OUR SERVICES AND QUALITY ]

1> Magnet will be inspected strictly during the production of every process.

2> Every magnet will have a certificate before delivery.

3> Magnetic Flux report and Demagnetization Curve can be offered according to request.

Depending on international quality rules and advanced inspection facilities, Jin Tong can achieve comprehensive inspections for the products, to ensure that each product satisfies customers.

DEMAGNETIZATION CURVE

Jin Tong magnet was established in 1995, with 28 years history in NdFeB magnets industry, which is the role-model enterprise among magnets manufacturing industries in China.

Our main factory is located in Changzhi city of Shanxi province, with 35000 square meters workshop. Our present total annual magnet products output is about 5000 tons.

--Established our branch companies in Guangzhou & Shenzhen city for fast service.

We warmly welcome you to contact us or visit our company, and look forward to establish a long term business relationship with you.

Jin Tong Factory Show:

With more than 500 sets advanced production instruments.

Production under oxygen-free environment for whole process.

Do not generate any waste gas or water or residue during production.

Magnet Production Process:

CWIEME BERLIN every year, Germany

CWIEME CHICAGO every year, USA

CANTON FAIR every year, China

You're more than welcomed to visit us at above exhibitions every year. We look forward to a face to face meeting with you.

Q1: Are you a factory or trade company?

A: We are specific in produce of neodymium magnet over 28 years and now has 2 factories in China.

Q2: Could i visit your factory, where is your factory?

A: Welcome,Our main factory located at Changzhi city, Shanxi province, The other branch plant locate at Guangdong province.

Q3: Could I speed up the buying process for the customized item?

A: The more information you have, the faster we can help you. It’s better to include:

a. the size and the tolerance

b. the property grade of the magnet

c. what kind of coating you want

d. the direction of the magnetization

e. the operating temperature and other environmental conditions in application

Q4: How do you control the quality?

1) We have been monitoring from raw materials to the whole production processes

2) various advanced testing instruments to ensure the quality stability

3) We have QC Department ensures an ongoing development and maintenance of high quality standards

4) Check the packing before delivery

If you have any questions, please feel free to contact us. |