Хорошая производительность автоматической VZH-168q квадратная стальная труба делая машину/Производственная линия трубы/ERW

- Категория: Pipe Making Machinery >>>

- Поставщик: Zhangjiagang,Acetech,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 59500.55 $* | 62475.24 $* |

| Aug-16-2025 | 59000.6 $* | 61950.73 $* |

| Jul-16-2025 | 49500.42 $* | 51975.72 $* |

| Jun-16-2025 | 58000.74 $* | 60900.90 $* |

| May-16-2025 | 50500.69 $* | 53025.95 $* |

| Apr-16-2025 | 57000.23 $* | 59850.88 $* |

| Mar-16-2025 | 56500.83 $* | 59325.63 $* |

| Feb-16-2025 | 56000.45 $* | 58800.58 $* |

| Jan-16-2025 | 55500.84 $* | 58275.9 $* |

Характеристики

Good performance Automatic VZH-168q Steel Pipe Making Machine/Pipe Production Line/ERW Tube Mill

Product Description

1. Company has passed ISO9000: 2008 version quality system certification and CE Certification of Pipe Mill,All manufacturing processes are strictly conducted by the standard.

2. All products adopt all-around computer aided design (CAD & CAXA & PRO-E & COPPRA).

3. Our manufacturing process control using ERP system.

4. From processing to each procedure of assembly, all the spare parts after the strict incoming inspection, assembly process of no-load test, the finished final inspection and testing

5. All auxiliary parts adopt international and domestic famous brand products.

2. All products adopt all-around computer aided design (CAD & CAXA & PRO-E & COPPRA).

3. Our manufacturing process control using ERP system.

4. From processing to each procedure of assembly, all the spare parts after the strict incoming inspection, assembly process of no-load test, the finished final inspection and testing

5. All auxiliary parts adopt international and domestic famous brand products.

Tips:

1. All prices and parameters shown above are automatically generated by the system, if you want to know the exact information, please click "Send Inquiry" to contact us.

2. Because of the time difference, we suggest that you can choose "Send Inquiry" instead of "Chat Now"

3. When sending us an inquiry or message, Please tell us your usual contact information, then our sales manager can contact you quickly.

1. All prices and parameters shown above are automatically generated by the system, if you want to know the exact information, please click "Send Inquiry" to contact us.

2. Because of the time difference, we suggest that you can choose "Send Inquiry" instead of "Chat Now"

3. When sending us an inquiry or message, Please tell us your usual contact information, then our sales manager can contact you quickly.

Product Paramenters

Model | Tube O.D. (mm) | Wall Thickness (mm) | Speed (m/min) | Main motor (KW) | H.F.Welde (KW) |

VZH-12 | φ4~12 | 0.2~0.5 | 30~120 | 15 | 100 |

Suitable Products

Flow Chart

GENERAL PROCESSING

{Steel strips} →→Double-head un-coiler →→Strip-head Shearer & Butt welder station →→Accumulator(Vertical cage or horizontal spiral loop) →→Forming M/C (Main driving unit① +Flattening Entry unit + Breakdown zone + Fin pass zone + Seam guide unit + High frequency induction welding system + Squeeze welding roller unit + Outside scarfing unit +Zinc spray Patching system for welded seam + Horizontal ironing stand) + Emulsion water Cooling section + Sizing M/C (Main driving unit② +Sizing zone + Speed testing unit + Turk straightener + Vertical pull-out stand) →→ NC flying saw under computer control (Hot friction saw or Cold saw)→→ Kick-out table

Product Detail

Un-coiler

Un-coiler machines can be divided into:

* Single-head hydraulic Un-coiler.

* Double-head pneumatic Un-coiler.

* Double-head hydraulic Un-coiler.

* Single-head hydraulic Un-coiler.

* Double-head pneumatic Un-coiler.

* Double-head hydraulic Un-coiler.

CNC

All the mill lathes,key grooves and bolt hoies are positioned and milled by CNC which makes the components and parts can be quickly and precisely loacted and fixed

Storage

Used to store raw material Carbon Steel, so that the machine can produce more smoothly

Divided into three storage methods:

* Vertical cage accumulator

* Horizontal loop accumulator

* Lander spiral loop accumulator

Divided into three storage methods:

* Vertical cage accumulator

* Horizontal loop accumulator

* Lander spiral loop accumulator

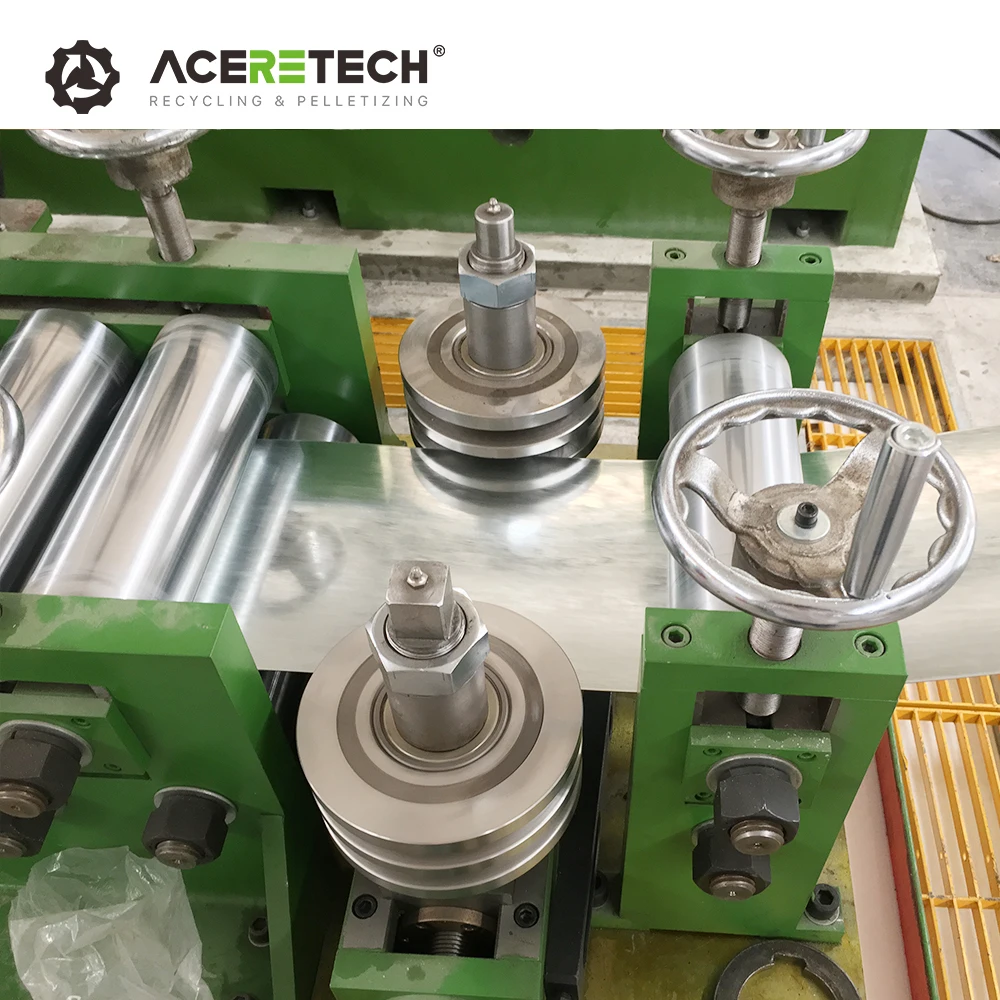

Forming & Sizing Mill

Use thick steel to weld together as a whole to tempering more than 4 hours twice to make sure that the machine can be used in

long-term without deformation. Equiped with greasing nozzles for the bearing lubrication,the bearing life is largely improved.

On-line and automatic roller quick-change system. Using bronze adjusting nut to protect screw,absorb shock as its self-repairing

characteristic. All the positioning keyways and bolt holes are processed by CNC machines, with high accuracy.

long-term without deformation. Equiped with greasing nozzles for the bearing lubrication,the bearing life is largely improved.

On-line and automatic roller quick-change system. Using bronze adjusting nut to protect screw,absorb shock as its self-repairing

characteristic. All the positioning keyways and bolt holes are processed by CNC machines, with high accuracy.

Precision Roller

The optimized design,high quality material selection and strict heat treatment process guarantee the high precision,wear-resisting

and long life of precision roller

and long life of precision roller

High Quality Roller

The optimized design,high quality material selection and strict heat treatment process guarantee the high precision,wear-resisting and long life of roller

Roller Quickly Change System

Patented design to help you change the roller in half an hour

Gear

Spiral bevel gear,drum gear coupling and carburization and quenching for gear teeth makes the driving system stable,efficient and wearable,with higher loading capacity and lower noise

Welding

Special precision unit for high-frequency welding to realize seamless welded pipe

Flying saw

Optional cold flying saw or hot flying saw Use high-speed HSS steel or TCT toothed saw blades for cutting Smooth operation and high cutting accuracy The saw blade has low cutting noise, no saw blade powder, and no harm to the human body The incision effect is good, without burrs.

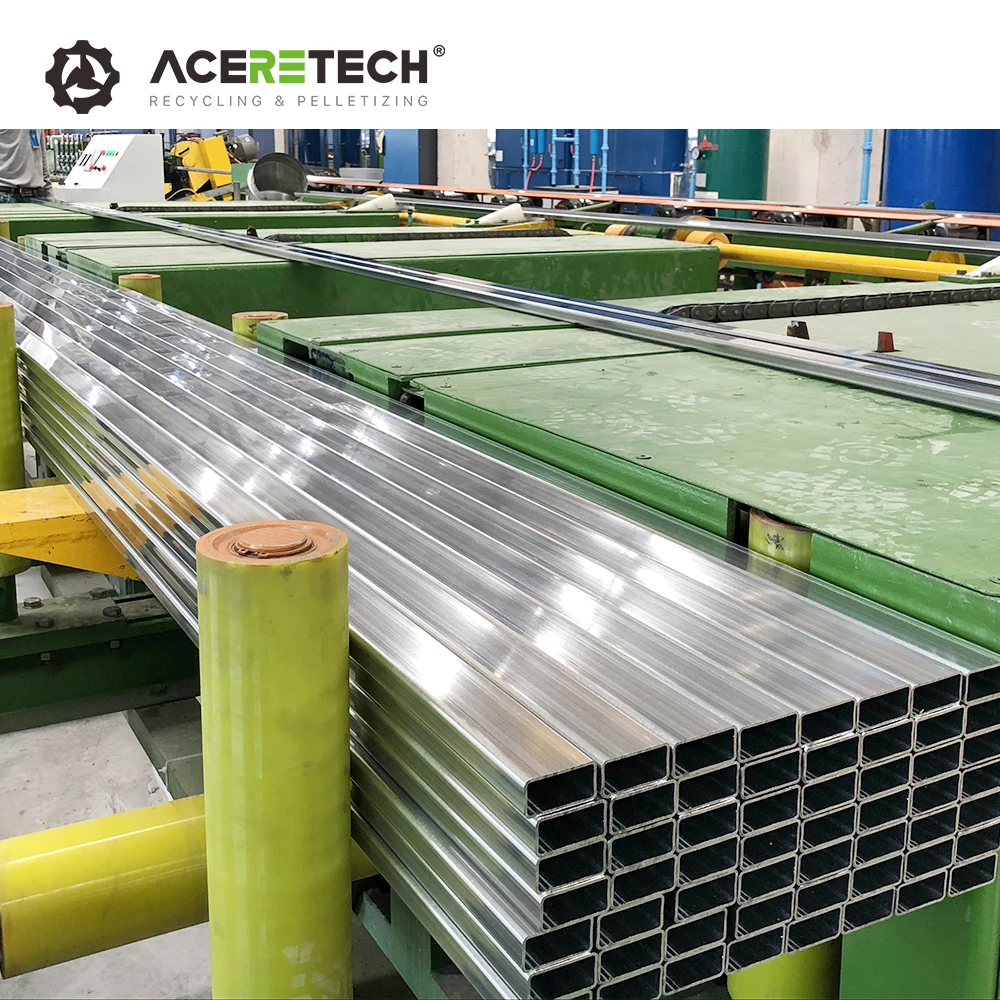

Conveyor Table

Able to ensure the smooth transmission of stainless steel pipes

Company Video

Our Company

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Похожие товары

Машина для производства локтей креветок

US $2200-$3800

Машина для изготовления декоративных труб

US $26500-$27500

Centrifugal Spun Concrete Pipe Machine

US $1000-$5000