Лабораторный стеклянный непрерывный пиролизный реактор с курткой Topacelab

- Категория: Reactors >>>

- Поставщик: Shanghai,Topace,Scientific,Instruments,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.53 $* | 0.63 $* |

| Aug-17-2025 | 0.25 $* | 0.66 $* |

| Jul-17-2025 | 0.80 $* | 0.48 $* |

| Jun-17-2025 | 0.54 $* | 0.65 $* |

| May-17-2025 | 0.47 $* | 0.93 $* |

| Apr-17-2025 | 0.46 $* | 0.35 $* |

| Mar-17-2025 | 0.83 $* | 0.18 $* |

| Feb-17-2025 | 0.46 $* | 0.51 $* |

| Jan-17-2025 | 0.68 $* | 0.65 $* |

Характеристики

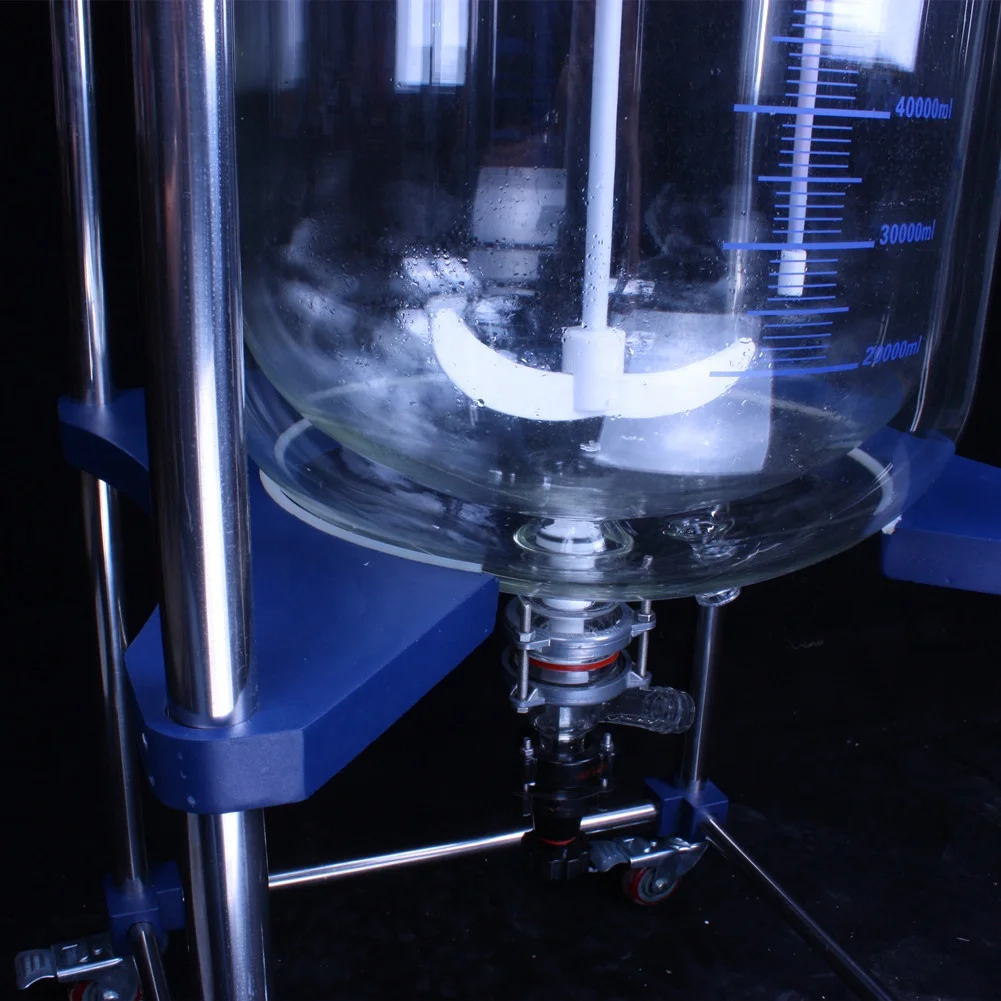

Topacelab 1- 200l Lab Glass Continuous Pyrolysis Reactor with Jacket

![]()

Introduce

This series glass reactor can be designed to be double glass reactor or three layers ofglass reactor. The inner layer adding the reactant to stirrer, jacketed layer can through theheating oil or coolant to do the distillation/cooled reaction. It takes reaction under Normal pressure or negative pressure and constant stirring.

It is mainly used for the process of combination, reaction, separation, concentration, etc. It is an ideal equipment for chemistry, finechemical, biopharmaceuticals, and the synthesis, test and production of new materials.

The reactor can be a system with circulating water vacuum pump, diaphragm vacuum pump,chiller /low temperature circulator, heating and heating and cooling circulating device.

Features

1. High quality borosilicate glass 3.3 has good chemical-physical attribute.

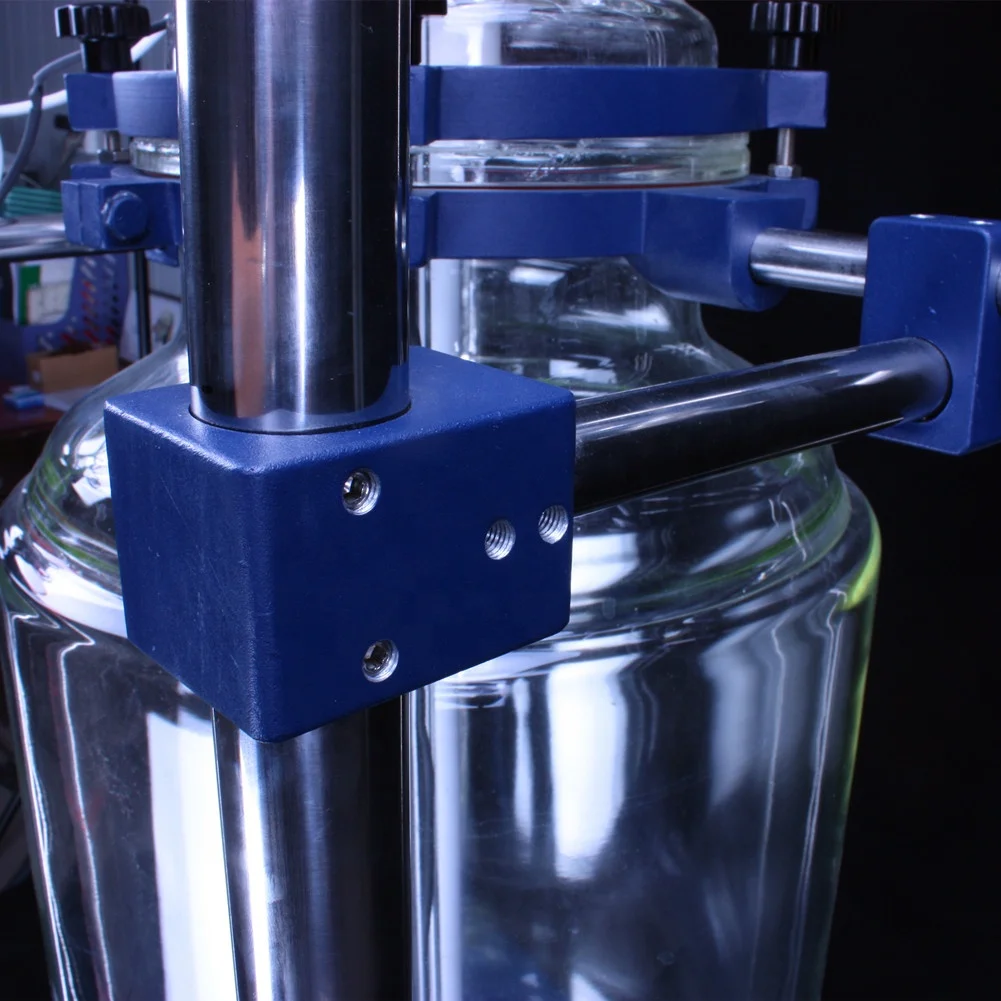

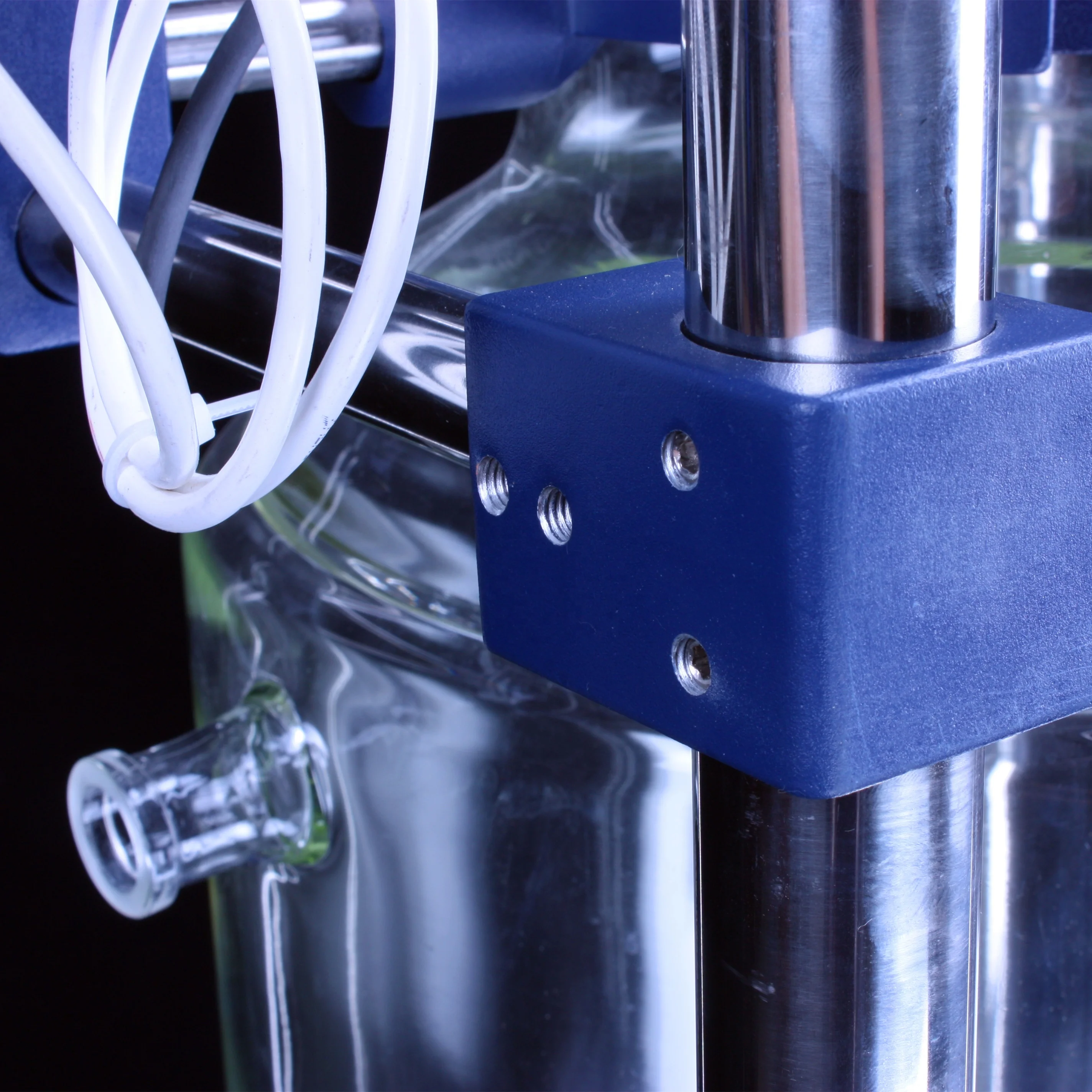

2. Low speed booster motor; High torque; no spark; frequency control, smooth operation.

3. PTFE rotary seal assembly; Patented product; High vacuum degree and long useful life.

4. PTFE discharge valve, discharge completely and quickly, no leak/pollution to the solvent.

5. PTFE stirring paddle, suitable for low and high viscosity liquid stirring and mixing.

6. Selection of our company's heating and cooling circulating device, we match standard

connector and the suitable connection pipe.

Main Specifications

| Basic Parameter | Type | JGR-100L(highly recommended) | 1L 2L 3L 5L 10L 20L 30L 50L 80L 150L 200L for you choose |

| Glass material | GG-17 | ||

| Frame material | Stainless steel | ||

| Pipe material | 304 stainless steel | ||

| Moving method | The band brake type universal angle wheel | ||

| Reaction bottle volume | 100L | ||

| Jacket capacity | 18L | ||

| Flange in and out of the oil circulation | Low “in” and high “out” | ||

| Number of kettle lid bottle | six | ||

| Distance between Discharging valve opening and ground | 450mm | ||

| Reaction temperature of reactor | -80-250℃ | ||

| Vacuum | 0.098Mpa | ||

| Stirring running speed | 0-450rpm | ||

| Stirring axis diameter | 15mm | ||

| Stirring power | 250W1/3 | ||

| Voltage/frequency (V/Hz) | 110V/ 220V/ 380V | ||

| Exterior size (mm*mm*mm) | 610*610*2500 | ||

| Packing size (mm*mm*mm) | 1920*720*970 1.34 square | ||

| Packing weight (KG) | 148 | ||

| Function configurations | Speed regulation method | Electric stepless speed regulation | |

| Motor configuration | Power motor at low speed, speed ratio is 3:1 | ||

| Rotary speed display | LCD digital display | ||

| Humidity display | PT100 sensor digital display | ||

| Sealing method | PTFE sealing, 60 flange stirring opening | ||

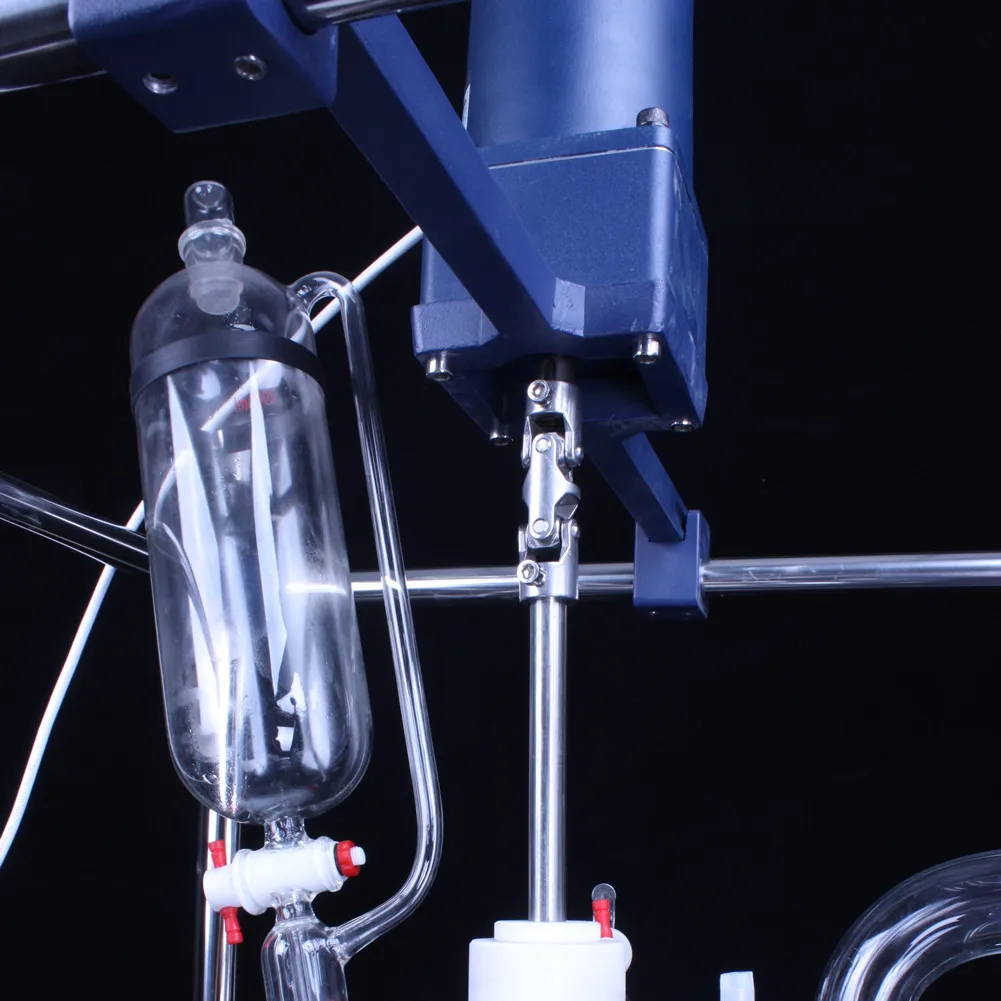

| Condenser | Vertical efficient double-reflux condenser120*640mm,40# standard opening | ||

| Reflow (distillation) device | Reflux bend with feeding switch, 50# ball mill mouth | ||

| Dropping device | 2L constant pressure funnel 40# standard opening | ||

| Pressure reducing device | 34#standard pressure reduce valve | ||

| Temperature measuring tube | 24#standard opening | ||

| Solid feeding | 80flange opening with PTFE lid | ||

| Discharging method | Bottom Side charging valve 80 flange opening | ||

| Vacuum display method | Vacuum meter | ||

| Stirring connection | Cardan joint connected | ||

| Stirrer | Writing stainless stick, coated by PTFE | ||

| Optional configurations | Main Frame | Tray type | |

| Collecting device | Collecting bottle | ||

| Explosion-proof | Ex-frequency inverter, Ex-motor EX370W, 0-1400 running speed | ||

| Frame parts | Plastic spraying or PTFE | ||

| Attemperator | Insulated cotton | ||

| Sealing parts | Ceramic bearing, mechanical seal | ||

| Condenser | Horizontal condenser can decrease whole height | ||

| Cover of reactor | Custom-made PTFE cover | ||

| Our laboratory glass and instruments are developed independently, we can manufacture according to customers’ demands. | |||

Packing and Delivery

The glass parts will be wrapped with foam material and cyslosepiment, then put into the carton, the mainbody portion will be packed in wooden cases, all parts will be packed in on wooden case;

Customized packaging can be available.

The damage caused by the transportation problem shall be borne by the seller.

By sea, by air, by train are both okay, You can also choose to use your own forwarder.

Turnkey Solution

when you receive them,you can use this system at once,it is very convenient.

Supporting Chiller

Supporting Vacuum Pump

I .Introduce

Our Company

Shanghai Topace scientific instruments co.,lt locates in Shanghai, specialized in product and export lab equipment such as rotary evaporator, jackteted glass reactor, short path distillation system, wiped film evaporator, vacuum oven, chillers, vacuum pumps, and stainless steel extraction tank and so on. With more than 30 years of experience on glass blowing, we provide a comprehensive range of products from lab glassware to industrygrade glass reactors (up to 200L) and evaporators (up to 100L). With the help of our experienced scientific glassblowers, we are able to quickly build customized glassware and prototype equipments, based on your sketch or pictures. Our equipment has been exported to theNorth America, Europe, Australia, South Africa, Southeast and East Asia, and other regions. You are warm welcomed to visit our factory!

FAQ

Q1: Can you provide OEM or ODM service?

A1: Yes, we have strong developing team to support OEM and ODM service. We can provide all kinds of customized services according to your request.

Q2: What's your MOQ?

A2: Any quantity is acceptable for your order. And the price is negotiable for large quantity.

Q3: What is your terms of delivery?

A3: FOB/ CIF /Door to Door/By air as you like.

Q4: The period, scope and condition of the warranty?

A4: 1.1We offer I years warranty on the date of shipping from China. During the warranty time, beeause of manufacturingkquality problem, we offer replacement, maintenance service.

1.2The damage caused by the transportation problem shall be borne by the seller.

Q5: How te solve the problem of your equipment?

A5: Please send us email of the problem, pictures or a small video will be much better. we will find the problem and tell you haw to solve it. If there is a broken, we will send you a new part and it is free in the warrant period.

Q6: How to shipping the replacement parts?

A6: We will according the actual situation to choose the suitable shipping ways. For small parts we shipping by Express.

Q7: Are you manufacturer?

A7: Yes, our factory has been for 30 years. Sincerely welcome to visit our factory any time.

Hot Deals