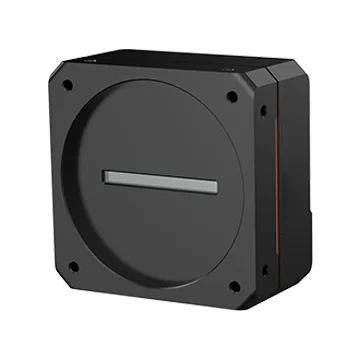

MV-CL086-91GC 8K пикселей камеры GigE 8192x6 линия сканирования CMOS промышленная камера

- Категория: Surveillance Products >>>

- Поставщик: Hangzhou,Huicui,Intelligent,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.54 $* | 0.3 $* |

| Aug-16-2025 | 0.41 $* | 0.65 $* |

| Jul-16-2025 | 0.63 $* | 0.2 $* |

| Jun-16-2025 | 0.38 $* | 0.63 $* |

| May-16-2025 | 0.84 $* | 0.20 $* |

| Apr-16-2025 | 0.66 $* | 0.37 $* |

| Mar-16-2025 | 0.62 $* | 0.96 $* |

| Feb-16-2025 | 0.60 $* | 0.90 $* |

| Jan-16-2025 | 0.96 $* | 0.4 $* |

Характеристики

Generate images by lines and output with high-precision

Key Feature

Supports image compression mode, TDI, triggerwidth exposure, etc.

Supports manual adjustment for Gamma correction,PRNUC correction, LUT, black level, etc.

Adopts bi-directional I/O hardware design.

Compact design and flexible installation.

Compatible with GigE Vision V2.0 and GenlCamb standard.

Paramters

| Model | Model | MV-CL086-91GC |

| Type | 8192 P CMOS GigE Line Scan Camera | |

| Camera | Sensor type | CMOS |

| Pixel Size | 5 μm | |

| Resolution | 8192×6 | |

| Image mode | Supports 1-line, 2-TDI | |

| Max. Line Rate | 14 kHz @Bayer 8/Mono 8, 7 kHz @Bayer 10/Mono 10, 4.7 kHz @RGB 8/BGR 8 Image compression mode: 40 kHz @Bayer 8, 20 kHz @Bayer 10, 14 kHz @RGB 8 | |

| Dynamic range | 54.8 dB | |

| SNR | 40.3 dB | |

| Gain | Supports 1.2 ×, 2.7 ×, 4.6 × | |

| Exposure time | 3 μs to 10 ms | |

| Exposure mode | Off/ Once/ Continuous exposure mode, and supports trigger-width exposure | |

| Mono/Color | Color | |

| Pixel format | Mono 8/10, Bayer RG 8/10, RGB 8, BGR 8 | |

| Binning | Not support | |

| Reverse image | Supports horizontal reverse image output | |

| Trigger mode | External trigger, internal trigger | |

| External trigger mode | Line trigger, frame trigger, line + frame trigger | |

| Electrical features | Data Interface | GigE |

| Digital I/O | 12-pin Hirose connector provides power and I/O: configurable input or output × 4 (Line 0/1/3/4) and support single-ended/differential | |

| Power supply | 12 VDC to 24 VDC | |

| Power consumption | Typ. 13.0 W@12 VDC | |

| Mechanical | Lens mount | M72 *0.75, optical back focal length: 12 mm (0.5") |

| Dimension | 80 mm × 80 mm × 46.3 mm (3.1" × 3.1" × 1.8") | |

| Weight | Approx. 465 g (1.0 lb.) | |

| Ingress protection | IP40 (under proper lens installation and wiring) | |

| Temperature | Working temperature: -20 °C to 55 °C (-4 °F to 131 °F) Storage temperature: -30 °C to 80 °C (-22 °F to 176 °F) | |

| Humidity | 5% to 90% RH, non-condensing | |

| General | Client software | MVS or the third-party software meeting with GigE Vision protocol |

| Operating system | 32/64-bit Windows XP/7/10, 32/64-bit Linux, and 64-bit MacOS | |

| Compatibility | GigE Vision V2.0, GenICam | |

| Certification | CE, FCC, RoHS, KC |

Drawings

Accessaries

Line scan applications

Line scan systems are mainly used for inspection of continuous material. They are also well suited for applications requiring extremely high resolution or speed, or for the inspection of cylindrical or rotating objects.

Web inspection

A typical field of application for line scan cameras is the inspection of a continuous product such as a textile, paper, glass or steel plate. These objects have no defined beginning or end and can be thought of as infinite in length.

Conveyor belts

Imaging objects on a conveyor belt is also an excellent use for line scan technology, especially if the objects under inspection vary in length and a high resolution image is required. Capturing images with an area scan camera would require a vertical field of view large enough for the biggest part, limiting the resolution. In addition, illuminating large areas can be a problem. Line scan gets round these problems by effectively varying the image height depending on start/stop signals derived from the part as it moves past the camera. In addition it is far easier to illuminate a single line across the conveyor.

Rotating objects

Line scan is also a very convenient way of imaging cylindrical components. Trying to do this with an area scan camera would be difficult and would involve correcting the distortion caused by imaging the curved surface, plus having to take multiple images to capture the entire surface. A line scan camera records the same optical position across the whole cylinder eliminating distortion; rotating the cylinder will generate an "unwrapped" image of the entire surface.

Located in Hangzhou, Mstar Technologies, Inc is a professional manufacturer of machine vision products. We have over 6 years of experience in machine vision and have a good reputation in this field.

Quality and Safety: We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

1. When will you ship my order?

Generally, once we get confirmation for payment, we will ship the order within 7-10 days. The specific delivery time depends on the items and the quantity of your order.

2. Does OEM/ODM available?

Yes, just let us know your details, then we can help you to design and put it into production.

3. The sample request is ok? if so, for free?

Re: MOQ is needed for a factory but one sample for testing is acceptable. We'd like to see our customer having a try on our products. But sorry, it's not for free, you need to pay for it.

4. Driver and SDK problems?

Re: We will provide the SDK with the camera for free. And if you meet any problems when using it, just feel free to let us know.

5. Payment Term Credit card, VISA card, e-checking, PayPal, Western Union, TT.

6. Could I print our logo or company name on our products?

Re: Of course, we could print your logo or company name as your requirements, but you need to send us your logo certification and the certificate of authorization.

Mstar Technologies, Inc.

Add.: 4/F, Building 19, No. 998 Wenyi West Road, YuHang District

Hangzhou Zhejiang 311121 China

Tel: 86-571-26280523

E-Mail: fangjl @hc-vision.cn