Кислородный компрессор устройство для наполнения O2 кислородный усилитель

- Категория: Industrial Compressors >>>

- Поставщик: Hangzhou,Nuzhuo,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.9 $* | 0.64 $* |

| Aug-19-2025 | 0.36 $* | 0.52 $* |

| Jul-19-2025 | 0.48 $* | 0.16 $* |

| Jun-19-2025 | 0.26 $* | 0.31 $* |

| May-19-2025 | 0.73 $* | 0.83 $* |

| Apr-19-2025 | 0.8 $* | 0.11 $* |

| Mar-19-2025 | 0.61 $* | 0.22 $* |

| Feb-19-2025 | 0.86 $* | 0.80 $* |

| Jan-19-2025 | 0.11 $* | 0.94 $* |

Характеристики

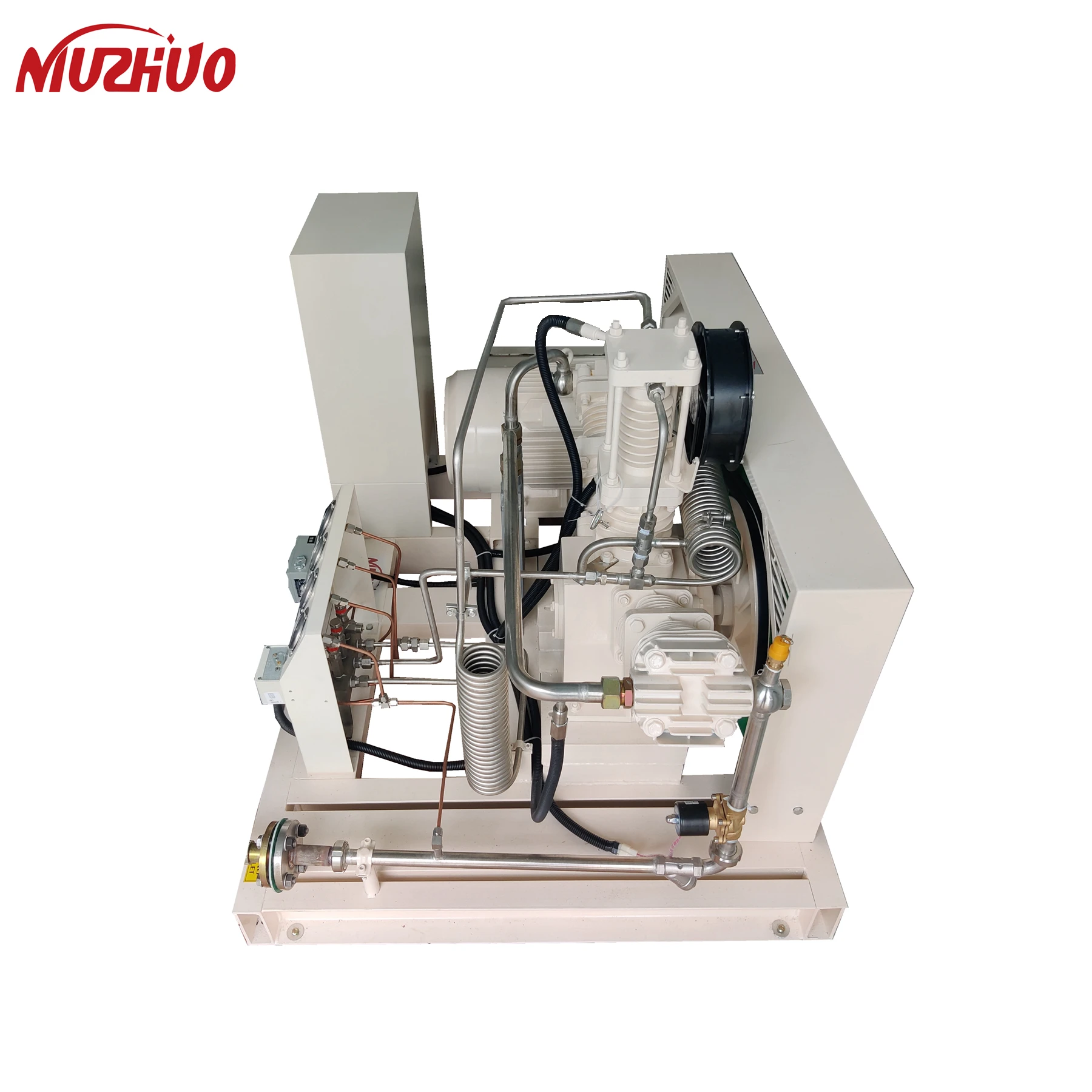

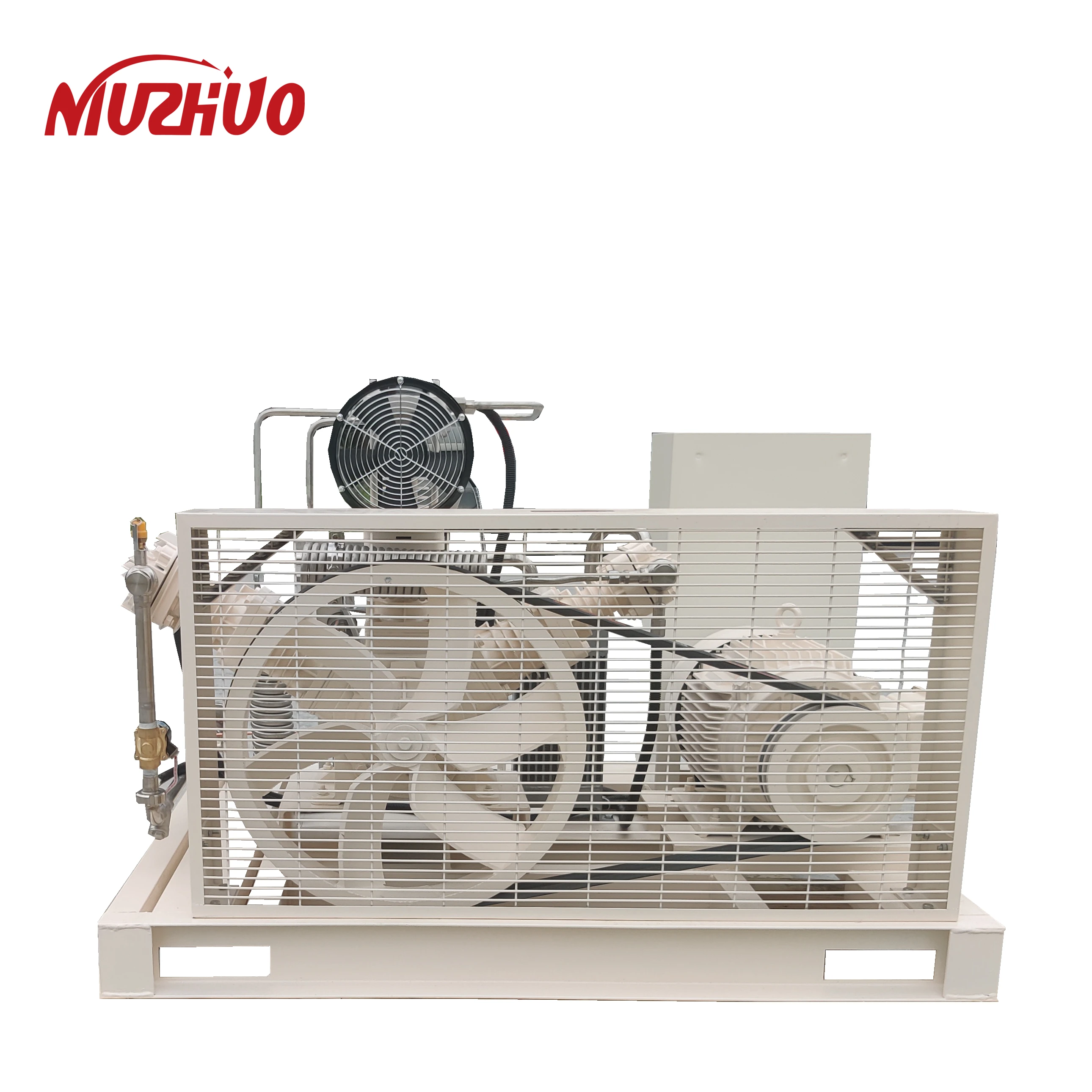

Products Description

Product Name | Oil Free Gas Compressor | ||||||

Power Range | <55KW | ||||||

Model No. | GWX- 5/10/20/40/60/80/CUSTOMIZED | ||||||

Cooling Method | Air-cooled or Water-cooled | ||||||

Speed Range | 300-600r/min | ||||||

Compression Stages | Level 3-4 | ||||||

Exhaust Pressure Range | ≤25.0Mpa | ||||||

Inspiratory Pressure Range | 0-0.6Mpa | ||||||

Technical features

The equipment does not need to add lubricating oil, and the exhaust gas does not contain oil and oil vapor, so it can be protected from pollution, eliminating the need for complex filtration and purification systems, saving equipment costs and maintenance costs, and has significant features such as safety, reliability, and easy operation.

Technical features

Application Field

Details Images

Customer Photos

NZ0-30, NZO-60 PSA OXYGEN PLANT EXPORTED TO MYANMAR IN AUG – NUZHUO

The PSA oxygen generator plant with 30Nm3 production, oxygen purity with 93-95%, the local government come to inspect our equipment operation and oxygen quality etc, until now our company have sold around 80 sets oxygen plant to Myanmar, and cryogenic oxygen production line, with 99.6% oxygen purity, for filling cylinder or pipeline to hospital use.

THE MAX CAPACITY NZO-200 PSA OXYGEN GENERATOR FOR COMBUSTION-SUPPORTING

PSA oxygen generator meets the requirement of industrial, this 200Nm3/h machine use to producing oxygen for combustion, and this model is the max capacity for this type. Also PSA oxygen plant used for the medical hospital, we have exported to many countries, #Myanmar, #India, #Peru, #Russia, etc. Which support to connect to hospital oxygen tube directly, as well as filling into cylinders( we will supply filling station for you).

PURITY 99.6% LIQUID OXYGEN 10 TONS PER DAY - 20000L CRYOGENIC LIQUID OXYGEN TANK

In the end of 2021, unit 300Nm3/h cryogenic liquid oxygen production line ( Model: NZDO-300Y ) will delivery to Russia by air. And another set cryogenic oxygen plant will delivery after holiday, we are factory you know, and the size is customize.

How to get gaseous oxygen from liquid form? Equipped with vaporizer and cryogenic liquid pump, filling manifold, oxygen cylinders, the liquid oxygen become to compressed gaseous oxygen, and then filling into cylinders.

CRYOGENIC AIR SEPARATION PLANT - MODEL NZDON-150-150 TO RUSSIA, KENYA, ETHIOPIA

Specification: Producing 150Nm3/h liquid or gaseous oxygen with ≥99% purity and 150Nm3/h liquid or gaseous nitrogen with 99.999% purity.

Scope of supply: Air compressor system, Pre-cooling system, Air purification system, Fractionating column system ( cold box ),Turbo expander system, Filling system, Instrument and electric control system, Drawing design, etc

Scope of supply: Air compressor system, Pre-cooling system, Air purification system, Fractionating column system ( cold box ),Turbo expander system, Filling system, Instrument and electric control system, Drawing design, etc

HOURLY 3-200 CUBIC METER FLOW RATE GAS BOOSTER-FOR CYLINDERS FILLING- NUZHUO

If you want to fill into cylinders, oxygen, nitrogen or other gas, you should equip with all oil free high pressure gas compressor and filling manifold. We can provide full set oxygen plant, also the filling station alone, noted that we are factory, supply the machine directly.

We have sold to our machine to India, Peru, Myanmar, Ukraine, Kazakhstan, Algeria and other global countries. And we will provide the technical service lifetime.

Recommend Products

PSA OXYGEN GENERATOR

Following the principle of pressure swing adsorption zeolite molecular sieve is used as the adsorbent. A full set PSA oxygen plant consists of 5 parts. Fresh air as raw material, passing through air compressor obtain 5-10 Bar compressed air. After compressed air purification system the waste gas, water, oil, dust will be filtered and exhausted You can connect with hospital tube or another pipes to use directly, but also you can fill into cylinders.if so, we can supply oxygen booster and filling manifold.

PSA NITROGEN GENERATOR

PSA nitrogen generation adopts carbon molecular sieve as adsorbent whose capacity of adsorbing oxygen is larger than adsorbing

nitrogen. The two adsorbers (a&b) alternately adsorbing and regenerating to separate oxygen from nitrogen in air to obtain purified nitrogen by Auto-operated valves controlled by PLC.

LIQUID NITROGEN GENERATOR

Our medium size oxygen/nitrogen plants are designed and manufactured with the latest cryogenic air separation technology, which is

trusted as the most efficient technology for high rate of gas generation with high purity. We have world-class engineering expertise enabling us to build industrial gas systems in compliance with internationally approved manufacturing and designing standards.

VPSA OXYGEN GENERATOR

VPSA oxygen generator uses zeolite molecular sieve as the adsorbent, and uses the principle of pressure adsorption and decompression desorption to adsorb and release oxygen from the air, thereby separating oxygen from the automatic equipment. N2

molecules have a faster diffusion rate in the micro pores of zeolite molecular sieve, and O2 molecules have a slower diffusion rate.

CRYOGENIC OXYGEN PLANT

The basic principle of air separation is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The whole device can be controlled by DCS or PLC system.Pic shown is the key part of this system that is separation column (Cold box).

GAS COMPRESSOR

The equipment does not need to add lubricating oil, and the exhaust gas does not contain oil and oil vapor, so it can be protected from pollution, eliminating the need for complex filtration and purification systems, saving equipment costs and maintenance costs, and has significant features such as safety, reliability, and easy operation.

OXYGEN CONCENTRATOR

Oxygen Production is 5-60L/min, using pressure swing adsorption technology, purity is ≥90% for household and hospital use. The

product is mainly composed of compressor, zeolite molecular sieve, transfer switch,control panel, display board, flow meter, condenser, automatic drain and other components. If you need to add automization components (automization cup, connecting pipe, etc.).

Company Profile

Packing & Delivery

Q1: Are you a trading company or manufacturer?

A: We are a manufacturer.

Q2: What is your term of payment?

A: T/T 30% in advance and T/T 70% balance paid before shipment.

Q3 How long is your delivery time?

A: About 30 days.

Q4: What is your product quality assurance policy?

A: We offer a warranty period of 1 year or 1000 running hours whichever comes first.

Q5: Do you offer OEM/ODM service?

A: Yes.

Q6: Do you have ATS system?

A: Yes, it is optional.

A: We are a manufacturer.

Q2: What is your term of payment?

A: T/T 30% in advance and T/T 70% balance paid before shipment.

Q3 How long is your delivery time?

A: About 30 days.

Q4: What is your product quality assurance policy?

A: We offer a warranty period of 1 year or 1000 running hours whichever comes first.

Q5: Do you offer OEM/ODM service?

A: Yes.

Q6: Do you have ATS system?

A: Yes, it is optional.