С двойной рубашкой смешивания танк нержавеющая Steel304/316 вакуума для перемешивающего устройства смесительный бак

- Категория: >>>

- Поставщик: Jiangsu,Speed,Precision,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.39 $* | 0.6 $* |

| Aug-16-2025 | 0.36 $* | 0.56 $* |

| Jul-16-2025 | 0.95 $* | 0.82 $* |

| Jun-16-2025 | 0.62 $* | 0.5 $* |

| May-16-2025 | 0.96 $* | 0.86 $* |

| Apr-16-2025 | 0.98 $* | 0.76 $* |

| Mar-16-2025 | 0.59 $* | 0.52 $* |

| Feb-16-2025 | 0.80 $* | 0.30 $* |

| Jan-16-2025 | 0.6 $* | 0.13 $* |

Характеристики

Product Details

Heated Double Jacketed Mixing Tank, Stainless Steel304/316 Vacuum Agitator Mixer tank for liquid soap

Stainless steel mixing tanks are widely applied in the beverage, food, dairy, pharmaceutical, chemical and process industries used as blender tank, buffer tank and storage tank, which cleanable to sanitary standards .

Structure characteristics:

Made of single-layer stainless steel structure.

Materials are all sanitary stainless steel.

Humanized structure design and easy to operate.Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation.

Structure characteristics:

Made of single-layer stainless steel structure.

Materials are all sanitary stainless steel.

Humanized structure design and easy to operate.Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation.

Material | Stainless steel 304 ,SS316/316L |

Working Capacity | 50-40000L,customize |

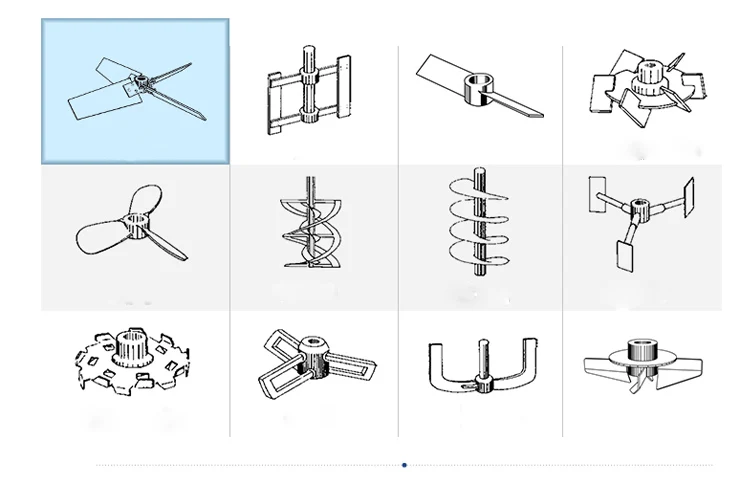

Agitator type | Mixer, emulsifier, disperser, etc. |

Layer | 1. Single layer type2. Double layer type: (1) dimple jacket (2) U type jacket (3) Coil jacket 3. There layer type: add the insulation layer |

Specification

Heating mixing tank

The electric heating stirring tank is an open-top structure, which has the functions of heating, automatic temperature control, heat preservation, and stirring; it has the advantages of fast heat transfer, large temperature differences, and convenient cleaning. It is widely used in food (dairy) products, pharmacy, daily chemical, beverage, oil, chemical, paint and other industries for heating, mixing or sterilization. It is especially suitable for small and pilot test use in units and scientific research institutions without steam heat source. It can also adopt a fully enclosed structure as required by the process.

high-shear emulsifier

The high-shear emulsifier uses a high-speed rotating shear- ina wheel and a stationary shearing wheel to fully and rap- idly emulsify, homogenize and disperse the mixed liquid and mixture in the tank. lt is widely used in food, beverage, biopharmaceutical, fine chemical, pigment and other in- dustries to mix and emulsify materials to improve produc tion efficiency and material quality, especially for cMc, glues, oowders and other additives that are difficult to melt. Better use

Vertical Mixer

The vertical mixer should be used for the mixing of raw materials, and the inner plate is lined with polypropylene plate or stainless steel plate, so it is not easy to stick to the material. Wear-resistant, adopts cycloidal pinwheel reducer, which has the characteristics of compact structure, convenient operation, uniform mixing, convenient discharge and transportation, etc.

Company Profile

Certifications

Packing and Shipping