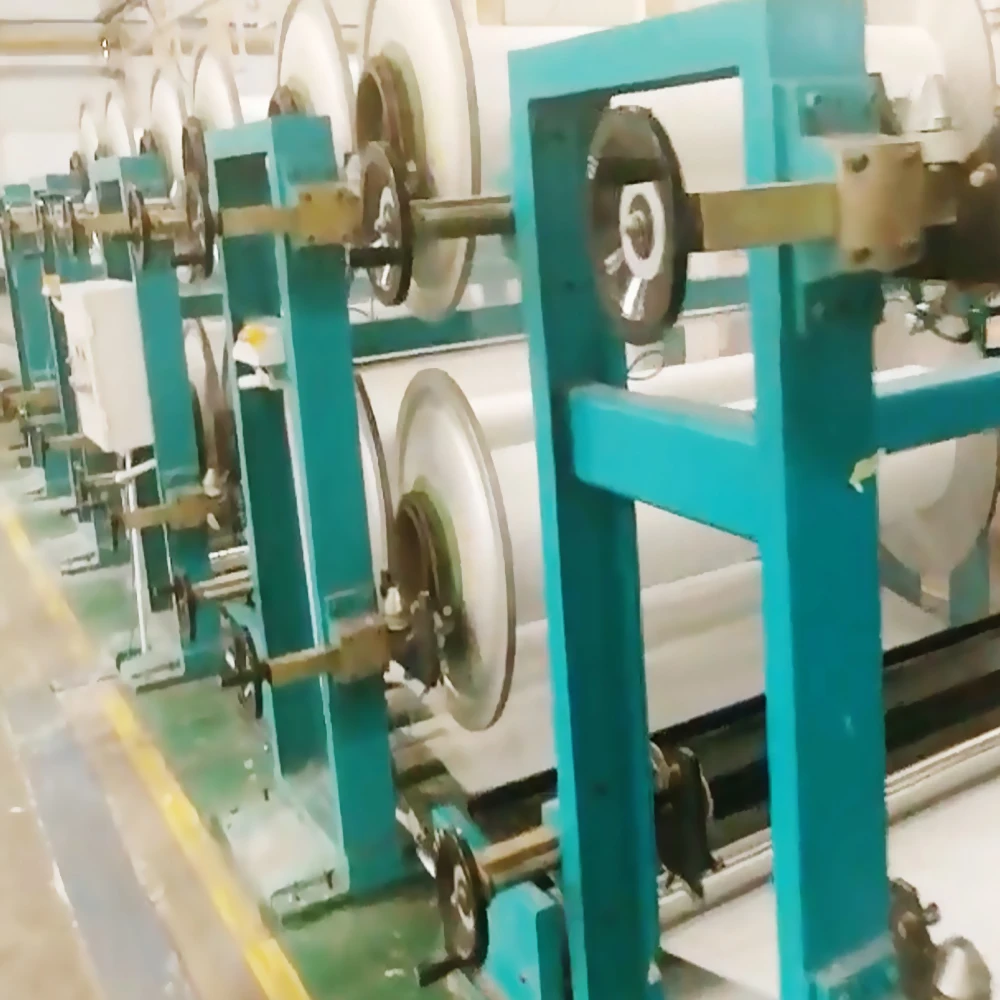

Текстильная машина для деформирования короткого волокна хлопчатобумажной пряжи

- Категория: Textile Dyeing Machines >>>

- Поставщик: Hefei,Kerrian,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.44 $* | 0.96 $* |

| Aug-15-2025 | 0.11 $* | 0.97 $* |

| Jul-15-2025 | 0.31 $* | 0.59 $* |

| Jun-15-2025 | 0.75 $* | 0.17 $* |

| May-15-2025 | 0.40 $* | 0.9 $* |

| Apr-15-2025 | 0.67 $* | 0.46 $* |

| Mar-15-2025 | 0.95 $* | 0.56 $* |

| Feb-15-2025 | 0.8 $* | 0.65 $* |

| Jan-15-2025 | 0.15 $* | 0.72 $* |

Характеристики

We produce sizing machine for Spun yarns,filament and glass fibre yarns.

High technique quality,good feedback from customers.Quality can compare with Karl Mayer,but price is much lower than Karl Mayer.

Sizing machine For the processing of spun yarns to high-quality warp beams

Typical features of our sizing machines are their high operator convenience and perfect process control; the sized warp beams ensure maximum efficiency in weaving. Combination size boxes with and without prewetting device ensure short yarn paths. Machines designed as one-box version (floor-type execution) and as double-box version (overhead execution) can be offered in different constructions to meet every requirement. Cylinder driers in various arrangements guarantee a rapid and gentle drying of the yarn.

. Ultimate technology & designs give highest quality sized warp beams.

. Fully auto control of all parameters by PLC.

. Zonewise constant stretch control by AC servo drive, load cell and PLC.

. Uniform, required size pick up.

. Low hairiness with uniform moisture.

. Low stretch.

. Easy reproducibility due to recipe data stored.

. Less Operator interference.

. Full safety during operation.

. Easy Supervision & operation due to graphics display & data save of actual & set process

parameters.

What we can do for customer?

1. full communication before making contract

1) Fully understand what customer want to make,and make project offer

2) Invite customer to China,to view whole production line process,then make contract

3) Visit customer’s factory,to Check layout design and Construction details

2. Comminicate on time after making contract?

1) Produce and deliver goods according to the time agreed in the contract,We will inform the customer of the production progress, and timely inform the customer in case of any accident, so as to make a response plan in advance

2) Packing and loading container in professional way,to make sure goods can be arrived safely.

3) Supply full correct documents,support customer to get custom clearance smoothly

4) Guide customer to unload machine,and check the goods by packing list.

3. Arrange visa and air ticket in advance when the goods arrive at customer’s factory.

Send good engineer to guide customer to install the equipment and trial the machine.

10 days more Training guidance is available after installation trial.

4. Customer can send 2-3 engineer to China,we will arrange them to get trainning in good factory,to learn management,working skill,and operation training.

5. Online service is available

6. Spare parts for reservition:we will advise customer to buy,also will give some for free.

1.What product do you have

Textile machine:Warping,beaming and sizing machine for cotton yarn,fiberglass yarn,filament yarn

Weaving machine:air jet loom and water jet loom

Dyeing machine:package yarn dyeing machine,cotton gauze bleaching machine

Other equipment:air compressor,warp tying machine,beam trolley and etc.

Gauze machine,packing machine etc.

2. What business are you doing?

We are trade company,boss is from different manufacturer.We are a tradelink company,give solution to our customer.