Подшипники Koyo все размеры конический подшипник дюймовый роликовый 07100/07204 957049/957010 7519 32216 32217 32218

- Категория: Taper Roller Bearings >>>

- Поставщик: Hefei,Rowiss,Bearing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.31 $* | 0.53 $* |

| Aug-19-2025 | 0.68 $* | 0.95 $* |

| Jul-19-2025 | 0.75 $* | 0.18 $* |

| Jun-19-2025 | 0.42 $* | 0.9 $* |

| May-19-2025 | 0.24 $* | 0.41 $* |

| Apr-19-2025 | 0.62 $* | 0.72 $* |

| Mar-19-2025 | 0.47 $* | 0.6 $* |

| Feb-19-2025 | 0.11 $* | 0.29 $* |

| Jan-19-2025 | 0.23 $* | 0.84 $* |

Характеристики

Product Description

Koyo Bearings All Sizes Tapered bearing inch tapered roller bearing 07100/07204 957049/957010 7519 32216 32217 32218 33222

ROWISS offers the most extensive line of tapered roller bearings in the world. Tapered bearings consist of four interdependent components: the cone (inner ring), cup (outer ring), tapered rollers (rolling elements) and cage (roller retainer). They manage both thrust and radial loads on rotating shafts and are available in three

configurations:

Single-row Tapered Roller Bearings: Most basic and widely used tapered bearing. Usually fitted as one of an opposing pair. During equipment assembly, can be set to the required clearance (end play) or preload condition to optimize performance.

Double-row Bearings: Two-row tapered bearing arrangements offer increased load capacity over single types.

Four-row Bearings: Combine the inherent high-load, radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings into assemblies of maximum load rating in a minimal space.

Single-row Tapered Roller Bearings: Most basic and widely used tapered bearing. Usually fitted as one of an opposing pair. During equipment assembly, can be set to the required clearance (end play) or preload condition to optimize performance.

Double-row Bearings: Two-row tapered bearing arrangements offer increased load capacity over single types.

Four-row Bearings: Combine the inherent high-load, radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings into assemblies of maximum load rating in a minimal space.

Some common models

32004--32022 30202--30220 30302--30320 32205--32226 32303--32320 27305----27310 33005--33030 33108--33124 33205--33221 7806--7821 7606B--7617B 7710--7728 T2ED045--T2ED070 T7FC045--T7FC080 7908-7915 TR070904 TR0305-9 TR0607 TR 0708 TR0809 STA3072 STA5383 TR5510032 11749 11949 45449 48548 12749 12649 68149 501349 104948 67048 127509 768906

FEATURES OF TAPERED ROLLER BEARINGS

The inner ring assembly of a tapered roller is referred to as the cone, while the outer ring is called the cup.

Tapered rollers are guided by the cone back face rib.

This bearing design is suitable for heavy radial loading and a sizeable amount of axial loading.

The taper of the rollers and the cone raceways have a common apex on the bearing axis.

The angle between the cup raceway and the bearing axis is the contact angle.

The larger the contact angle the greater the bearings axial load capacity.

The cone and cup are separable simplifying bearing mounting.

Single row bearings can accommodate radial load and axial load in one direction.

Two single row bearings are used opposing each other to simplify setting of the proper clearance between the two rows.

The two row design can handle radial load and an axial load in either direction.

The two row design is available as a TDO (double outer race), or a TDI (double inner race).

Two row taper designs are normally supplied with spacers to provide a pre-adjusted assembly.

The four row design is commonly used on rolling mill roll necks for their large load carrying capacity.

Cages used can be a pressed steel or a pin type.

MAIN APPLICATIONS

AUTOMOTIVE: Front and rear wheels, transmissions, differential pinion

OFF-HIGHWAY VEHICLES: Railroad, Construction, and Agricultural equipment

INDUSTRIAL: Rolling mill equipment, gear boxes, and machine tool spindles.

FEATURES OF TAPERED ROLLER BEARINGS

The inner ring assembly of a tapered roller is referred to as the cone, while the outer ring is called the cup.

Tapered rollers are guided by the cone back face rib.

This bearing design is suitable for heavy radial loading and a sizeable amount of axial loading.

The taper of the rollers and the cone raceways have a common apex on the bearing axis.

The angle between the cup raceway and the bearing axis is the contact angle.

The larger the contact angle the greater the bearings axial load capacity.

The cone and cup are separable simplifying bearing mounting.

Single row bearings can accommodate radial load and axial load in one direction.

Two single row bearings are used opposing each other to simplify setting of the proper clearance between the two rows.

The two row design can handle radial load and an axial load in either direction.

The two row design is available as a TDO (double outer race), or a TDI (double inner race).

Two row taper designs are normally supplied with spacers to provide a pre-adjusted assembly.

The four row design is commonly used on rolling mill roll necks for their large load carrying capacity.

Cages used can be a pressed steel or a pin type.

MAIN APPLICATIONS

AUTOMOTIVE: Front and rear wheels, transmissions, differential pinion

OFF-HIGHWAY VEHICLES: Railroad, Construction, and Agricultural equipment

INDUSTRIAL: Rolling mill equipment, gear boxes, and machine tool spindles.

Specification

item | value |

Type | Roller |

Structure | Taper |

Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Energy & Mining, Other |

Brand Name | NSK KOYO NTN NACHI or ROWISS |

Model Number | 07100/07204 957049/957010 7519 32216 32217 32218 33222 |

Precision Rating | P0 P6 P5 P4 P2 |

Seals Type | open |

Number of Row | Single Row |

Place of Origin | China |

Material | Chrome Steel GCr15 |

Cage | Steel Cage |

Feature | Long Life .durable |

Quality | ISO Standard |

Precision | P0 P4 P6 P5 P2 |

Service | OEM Service.Design Service |

Sample | Availble |

MOQ | 1PCS |

Delivery | 1~15days |

What Customer Say

Why Choose Us

Why choose us?

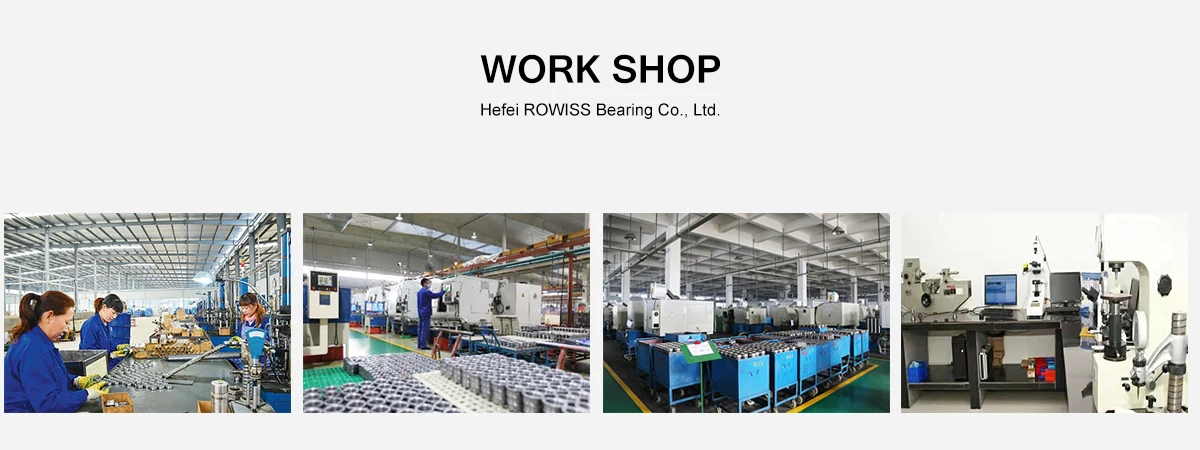

3 professional joint venture bearing factories with 204300 square meters

10 years rich export experience and know how to do

183 rich experienced employee work for you

10 million USD export turnover for 42 countries in 2020

Custom made and small order are ok with prompt delivery

Complete quality assurance with ISO 9001, ISO 14000 and TS 16949

OUR DIFFERENCE:We offer not only good bearings, but also our knowledge.

What we do?

ROWISS bearing export high quality bearings for our customers all over the world with very good price since 2000. We serve our target market for agricultural, electrical, fluid, industrial transmission, material handling, auto industry for many years.

Our strength products include as below:

Ball bearings

Auto bearings

Pillow block bearings and bearing units

Taper roller bearings

Agricultural bearings

70% products are exported to North America, West Europe and Asia.

What we do?

ROWISS bearing export high quality bearings for our customers all over the world with very good price since 2000. We serve our target market for agricultural, electrical, fluid, industrial transmission, material handling, auto industry for many years.

Our strength products include as below:

Ball bearings

Auto bearings

Pillow block bearings and bearing units

Taper roller bearings

Agricultural bearings

70% products are exported to North America, West Europe and Asia.

Zero Risk Commitment!

What we promise?

1. Quality commitment: All bearings are 100% inspected in the same standard with 12 months warranty when sent out. If quality problems occur, we will compensate according to the actual loss when you submit the third party report to us (such as SGS and Lloyd's, etc).

2. Delivery commitment: All goods will be delivered on time when the order confirmed. If the order will be delayed, the penalty must be executed by 100USD each day up to 5% the order total amount.

3. Service commitment: All emails will be replied within 1 hours during working time, the enquiry and order must be handled within 7 hours (8:30AM - 5:30PM, Monday - Friday). If you have any complaints with our service, please send your email to us, we are at your disposal.

2. Delivery commitment: All goods will be delivered on time when the order confirmed. If the order will be delayed, the penalty must be executed by 100USD each day up to 5% the order total amount.

3. Service commitment: All emails will be replied within 1 hours during working time, the enquiry and order must be handled within 7 hours (8:30AM - 5:30PM, Monday - Friday). If you have any complaints with our service, please send your email to us, we are at your disposal.

Recommend Products

FAQ

How to pack your goods?

All goods will be well packed and sent to you on time, we provide some packages upon your request:

1.Industrial packing+carton box+pallet

2.Single box+carton box+pallet

3.Logo packing design as per customers' request

How to pay?

ROWISS provide kinds of payment terms according to the total amount and your request, the payment terms include:

T/T (the order total amount<100000USD normally)

L/C (the order total amount>100000USD normally)

Cash, Paypal, Western Union, etc (normally for the sample, the freight and the mini order)

Other payment term can be discussed

What's the lead time?

The lead time depends on quantity and factory production status, we normally ship the goods to you:

Within 1-3 working days (if we have the ready goods in stock)

Within 3-15 working day (as per the actual order quantity )

How to delivery?

ROWISS must ensure that the goods can be delivered on time and unbroken to our customers. It depends on the cargo weight, value and customer requirements, we often offer four modes of transportion as below:

By courier

By sea

By air

By DDP (delivered duty paid)

Accepted delivery terms: FOB,CFR,CIF,EXW,DDP,Express Delivery

Guangzhou, Qingdao, Shanghai, Ningbo Port, etc as per customers' request

All goods will be well packed and sent to you on time, we provide some packages upon your request:

1.Industrial packing+carton box+pallet

2.Single box+carton box+pallet

3.Logo packing design as per customers' request

How to pay?

ROWISS provide kinds of payment terms according to the total amount and your request, the payment terms include:

T/T (the order total amount<100000USD normally)

L/C (the order total amount>100000USD normally)

Cash, Paypal, Western Union, etc (normally for the sample, the freight and the mini order)

Other payment term can be discussed

What's the lead time?

The lead time depends on quantity and factory production status, we normally ship the goods to you:

Within 1-3 working days (if we have the ready goods in stock)

Within 3-15 working day (as per the actual order quantity )

How to delivery?

ROWISS must ensure that the goods can be delivered on time and unbroken to our customers. It depends on the cargo weight, value and customer requirements, we often offer four modes of transportion as below:

By courier

By sea

By air

By DDP (delivered duty paid)

Accepted delivery terms: FOB,CFR,CIF,EXW,DDP,Express Delivery

Guangzhou, Qingdao, Shanghai, Ningbo Port, etc as per customers' request

Ask the prices now!

Get more discount today.

Please send your bearing list to info@rowiss.com for our official offer now!!

For example:

item no: 6000-2rs

qty: 20000pcs

quality: z3v3

packing: your single color box

Band: your logo needed

Band: your logo needed

Whatsapp: 0086 15555115239 for emergency.