Алюминиевая пластина плавник теплообменника детали алюминиевый для

- Категория: Refrigeration & Heat Exchange Parts >>>

- Поставщик: Nanjing,Mstirling,Technology,Co.,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 6.28 $* | 6.11 $* |

| Jul-17-2025 | 5.97 $* | 5.32 $* |

| Jun-17-2025 | 6.98 $* | 6.21 $* |

| May-17-2025 | 6.51 $* | 6.13 $* |

| Apr-17-2025 | 5.8 $* | 5.3 $* |

| Mar-17-2025 | 6.36 $* | 6.39 $* |

| Feb-17-2025 | 6.8 $* | 6.49 $* |

| Jan-17-2025 | 6.87 $* | 6.82 $* |

Характеристики

Product Description

Alumium alloy | AA3003,cladding AA4343/3003/4343,AA4004/3003/4004 are typical | ||||||

Temper | H14/H16/H24 are typical | ||||||

Length | As per required | ||||||

Width | Up to 450mm | ||||||

Height | Up to 40mm | ||||||

Wall thickness | 0.05 to 0.5mm | ||||||

Pitch | Up to 10mm | ||||||

Surface finish | Mill finish,a little oil allowed to protect fins | ||||||

Fins type | Plain,serrate,louver,perforated and corrugated forms are typical | ||||||

Packing way | To be packed in plywood case | ||||||

Application | Typically used in heat transfer fields | ||||||

Standard | GB,ISO,ASTM,DIN,etc. | ||||||

All our cooling radiator fins(customized oil/air/ cooling radiator fins) are customized made as per your request.

Fins are the basic components of plate-fin heat exchanger, on which the heat transfer depends. There are many types of fins,such as :Straight Fin, Perforated Fin ,Offset Fin ,Louvered Fin and Corrugated Fin which can meets various requirements.

Related Products

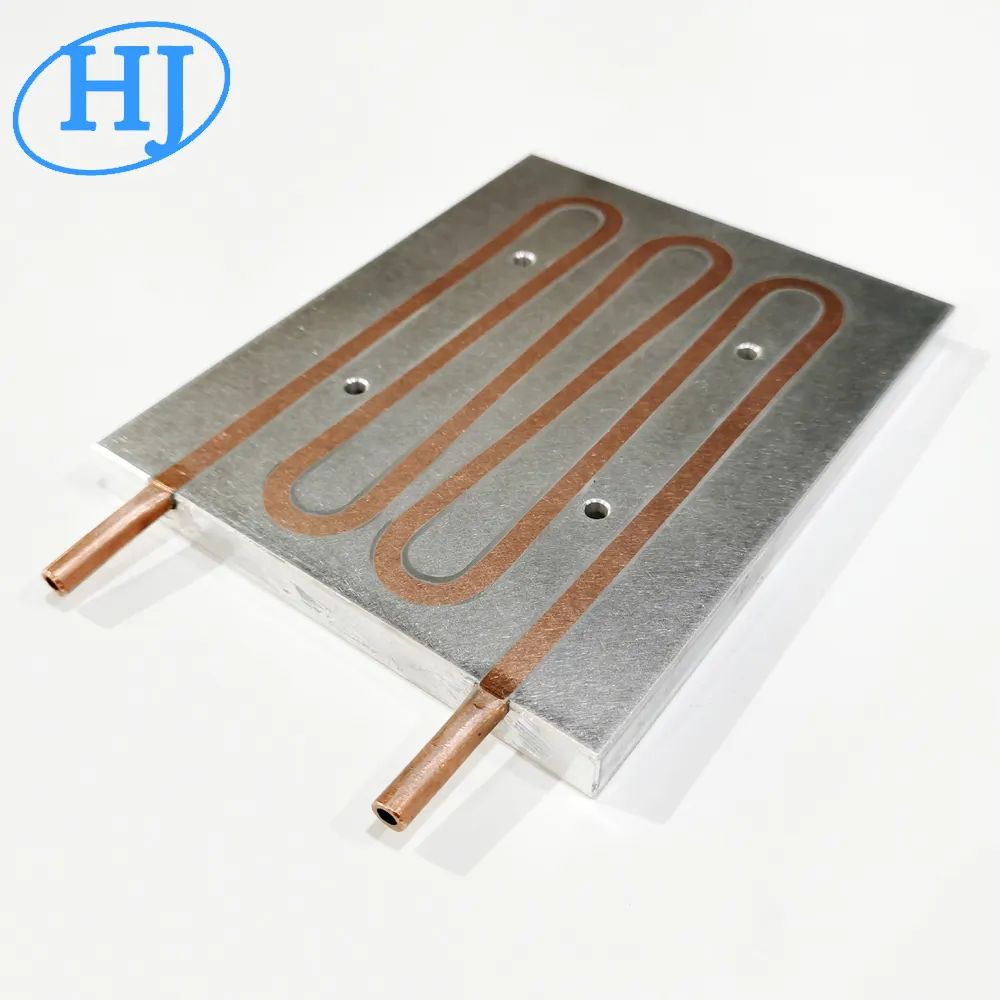

LIQUID COLD PLATE HEAT EXCHANGER

HEAT SINK HEAT EXCHANGER MATERIAL

Company Profile

Metalli’s main process capabilities includes:

☞ Vacuum brazing

☞ Control atmosphere brazing

☞ Welding

☞ CNC machining

☞ Aluminum extrusion

☞ Aluminum die casting

☞ Sheet metal fabrication

☞ Surface finish

☞ Assembly & packing

☞ Other Custom fabrication services

Quality Assurance

1. Quality assurance

a. Incoming material quality assurance; b. Process quality assurance; c. First sample quality assurance; d.

Final quality assurance.

Final quality assurance.

2. Process management-The right results are from the right process

a. Production process card control; b.Standard operational procedure;c.Job certification;d. Quality chart monitor.

3. Equipment and facility management

a. Periodic maintenance; b.Preventative maintenance.

4. Mold management

a. Mold life management; b.Periodic and preventative maintenance; c.Periodic inspection.

Thermal Simulation

Customer and We

Putting the customer first is the starting point and the key to our success

☛We translate their needs into business solutions.

☛We work closely with our customers and listen to customer's voices clearly to ensure their needs are clearly understood and transferred into our actions efficiently.

Product Application

Heater Radiator

Liquid cold plate Other heat transfer products

Contact us