Косметический бак для смешивания геля с алоэ вера отбеливающий увлажняющий водяной миксер 500 л

- Категория: Chemical Machinery & Equipment >>>

- Поставщик: Guangzhou,Aile,Automation,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 5950.9 $* | 6248.23 $* |

| Aug-18-2025 | 5900.1 $* | 6195.35 $* |

| Jul-18-2025 | 4950.24 $* | 5198.47 $* |

| Jun-18-2025 | 5800.94 $* | 6090.71 $* |

| May-18-2025 | 5050.59 $* | 5303.93 $* |

| Apr-18-2025 | 5700.80 $* | 5985.77 $* |

| Mar-18-2025 | 5650.4 $* | 5933.7 $* |

| Feb-18-2025 | 5600.44 $* | 5880.54 $* |

| Jan-18-2025 | 5550.58 $* | 5828.66 $* |

Характеристики

Parameter

capacity | 200-5000L(can be customerized) |

speed | 0-60 r/m |

mixing power | 0.75-15KW |

mixing speed | 0-65(R/MIN) |

heating method | Steam heating or electric heating (optional) |

homogenizer power | 2.2-22 KW |

homogenizer speed | 3000 (R/MIN) |

Product Description

Specification

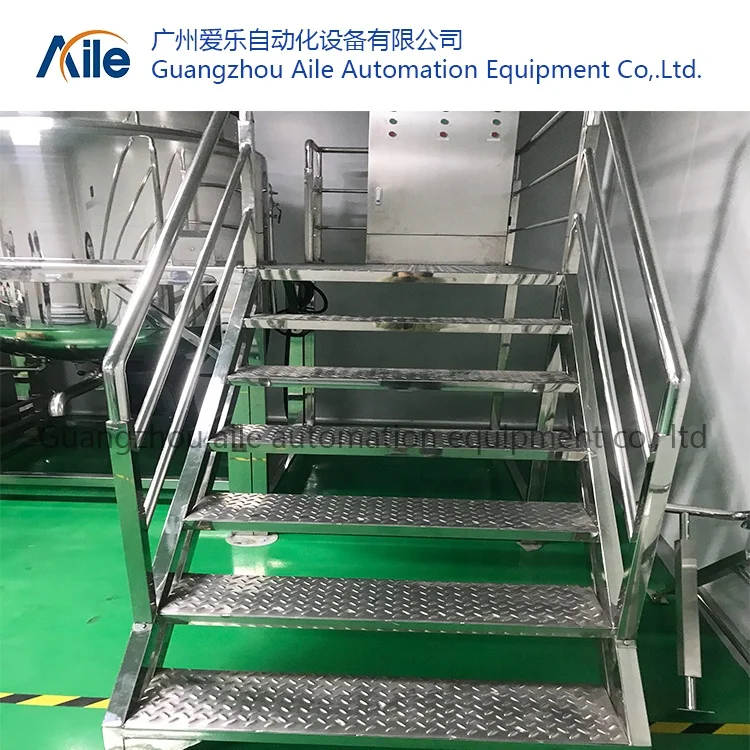

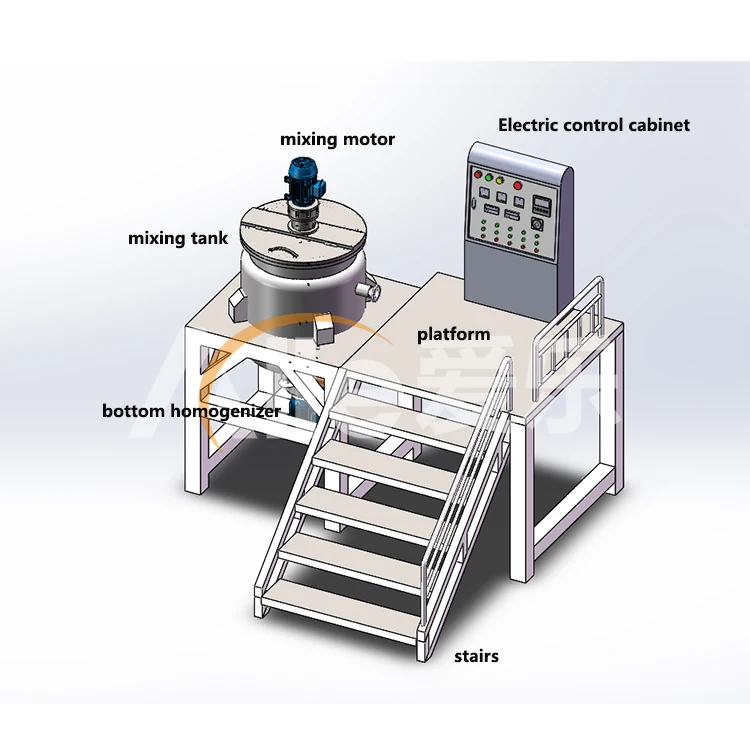

This machine is composed of pretreating boilers, emulsifying and blending boiler, hydraulic liftsystem, dumping system, eletric control system and work platform etc. Suitable for the production of shampoo, shower gel, hand sanitizer, detergent and other low viscosity products.

Characteristic

1. All materials are sanitary stainless steels.

2. Humanized structure design and easy to operate.

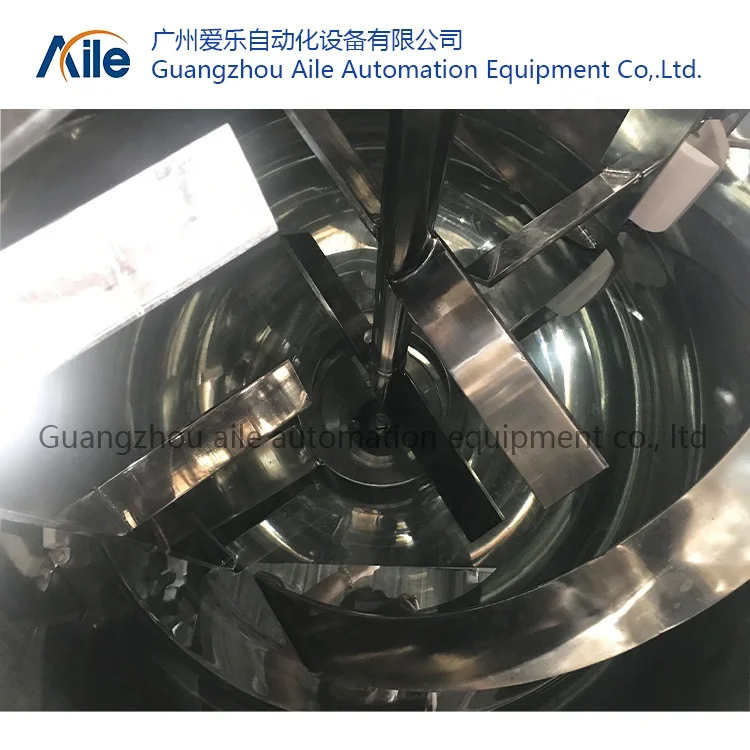

3. Transition area of interior wall on tank adopts arc transition to ensure that no dead ends of sanitation.

4. The storage tanks capacity are 100L,150L,200L,300L,500L,1000L Ect. suggested to put outside materials be SUS316L.

1. All materials are sanitary stainless steels.

2. Humanized structure design and easy to operate.

3. Transition area of interior wall on tank adopts arc transition to ensure that no dead ends of sanitation.

4. The storage tanks capacity are 100L,150L,200L,300L,500L,1000L Ect. suggested to put outside materials be SUS316L.

Features

1, the equipment consists of cabinet and blending tank.

2,There is advanced scraper blending machine, with the working of eccentricity, the PTPE (F4) composite plate touch the boiler correctly and solve the problem of sticking materials. The ideal stepless speed adjustment device, can adjust rotation within 0-60rpm willingly.

3, advanced homogenizing system imported from USA ROSS Company, the homogenizer is in the bottom to ensure homogenizing material even with small productivity. The sealing adopts recycled water cooling system and can work long time, conquer homogenizing problem regarding to high viscosity materials. A frequency conversion speed adjustment controller to satisfy kinds of complicate ingredients (Emulsifying capacity 3 times per minute) upper homogenizer as option to work with upper homogenizing and emulsifying so that the material emulsifying effect is better; product is more bright and luminous.

1, the equipment consists of cabinet and blending tank.

2,There is advanced scraper blending machine, with the working of eccentricity, the PTPE (F4) composite plate touch the boiler correctly and solve the problem of sticking materials. The ideal stepless speed adjustment device, can adjust rotation within 0-60rpm willingly.

3, advanced homogenizing system imported from USA ROSS Company, the homogenizer is in the bottom to ensure homogenizing material even with small productivity. The sealing adopts recycled water cooling system and can work long time, conquer homogenizing problem regarding to high viscosity materials. A frequency conversion speed adjustment controller to satisfy kinds of complicate ingredients (Emulsifying capacity 3 times per minute) upper homogenizer as option to work with upper homogenizing and emulsifying so that the material emulsifying effect is better; product is more bright and luminous.

Company Profile