OEM Заводская индивидуальная M1.4 M4 can Cross torx головка потайная черная саморез формирующий pt винт для пластиковой металлической

- Категория: Screws >>>

- Поставщик: Yu-Huang,Electronics,Dongguan,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 1.56 $* | 1.33 $* |

| Jul-15-2025 | 1.35 $* | 1.45 $* |

| Jun-15-2025 | 1.36 $* | 1.83 $* |

| May-15-2025 | 1.57 $* | 1.75 $* |

| Apr-15-2025 | 1.73 $* | 1.16 $* |

| Mar-15-2025 | 1.34 $* | 1.93 $* |

| Feb-15-2025 | 1.21 $* | 1.77 $* |

| Jan-15-2025 | 1.2 $* | 1.68 $* |

Характеристики

Material | Steel/Alloy/Bronze/Iron/ Carbon steel/etc |

Grade | 4.8/ 6.8 /8.8 /10.9 /12.9 |

specification | M0.8-M12 or 0#-1/2" and we also produce according to customer's requirement |

Standard | ISO,,DIN,JIS,ANSI/ASME,BS/Custom |

Lead time | 10-15 working days as usual,It will based on the detailed order quantity |

Certificate | ISO14001:2015/ISO9001:2015/ IATF16949:2016 |

Color | We can provide customized services according to your needs |

Surface Treatment | We can provide customized services according to your needs |

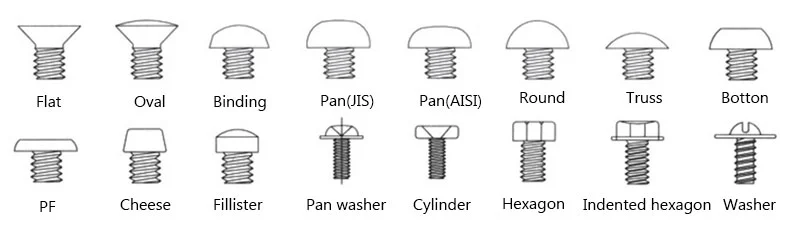

Head styles

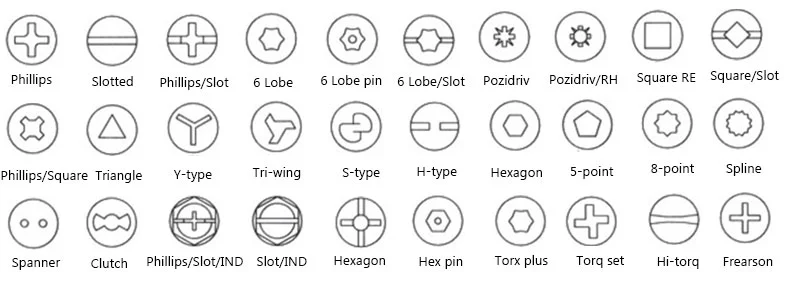

Drive type

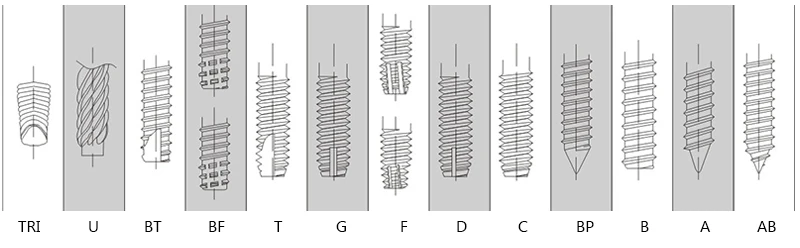

Points styles

Surface treatment method

Production process

Quality inspection

# | Process Name | Checking Items | Detection frequency | Inspection Tools/Equipments |

1 | IQC | Check raw material: Dimension, Ingredient, RoHS |

| Caliper, Micrometer, XRF spectrometer |

2 | Heading | Outward appearance, Dimension | First parts inspection: 5pcs each time Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours | Caliper, Micrometer, Projector, Visual |

3 | Threading | Outward appearance, Dimension, Thread | First parts inspection: 5pcs each time Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours | Caliper, Micrometer, Projector, Visual, Ring gauge |

4 | Heat treatment | Hardness, Torque | 10pcs each time | Hardness Tester |

5 | Plating | Outward appearance, Dimension, Function | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Ring gauge |

6 | Full Inspection | Outward appearance, Dimension, Function |

| Roller machine, CCD, Manual |

7 | Packing&Shipment | Packing, Labels, Quantity, Reports | MIL-STD-105E Normal and strict single sampling plan | Caliper, Micrometer, Projector, Visual, Ring gauge |

FAQ

Q1:Are you a factory or a trading company? We are manufacturer . 1.thus making sure you get the products with best price. 2.working with us, Factory direct sales, quality is more guaranteed. 3.however, in order to meet the needs of customers, we can also help customers integrate resources and assist customers in purchasing. (We are a manufacturer for making kinds of fasteners over 22 years, we have superior relevant suppliers.)

|

Q2:What types of customized parts do you provide? It can be made according to the drawings and specifications provided by customers.for your special needs. we manufacture suitable fasteners according to your product characteristics. |

Q3:Do you provide samples ? is it free or extra ? Yes, if we had stock the available goods or have available toolings, we could offer the sample for free charge within 3 days ,but do not pay the cost of freight. |

Q4:How does your company guarantee product quality? 1.Each link of our products has a corresponding department to monitor the quality.From the source to the delivery, the products are in strict accordance with THE ISO process, from the previous process to the next process flow, all are confirmed that the quality is correct before the next step. 2.We have a special quality department responsible for the quality of the products. The screening method will also be based on different screw products, manual screening, machine screening. 3.We have fully inspection systems and equipments from material to products, each step confirm the best quality for you. |