Производитель высококачественных пластиковых деталей для

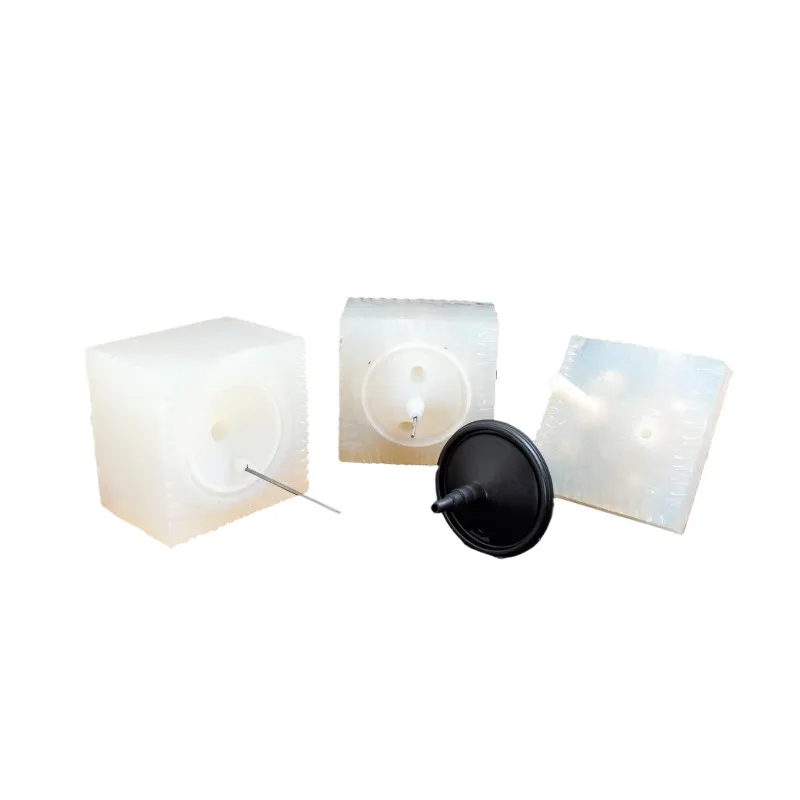

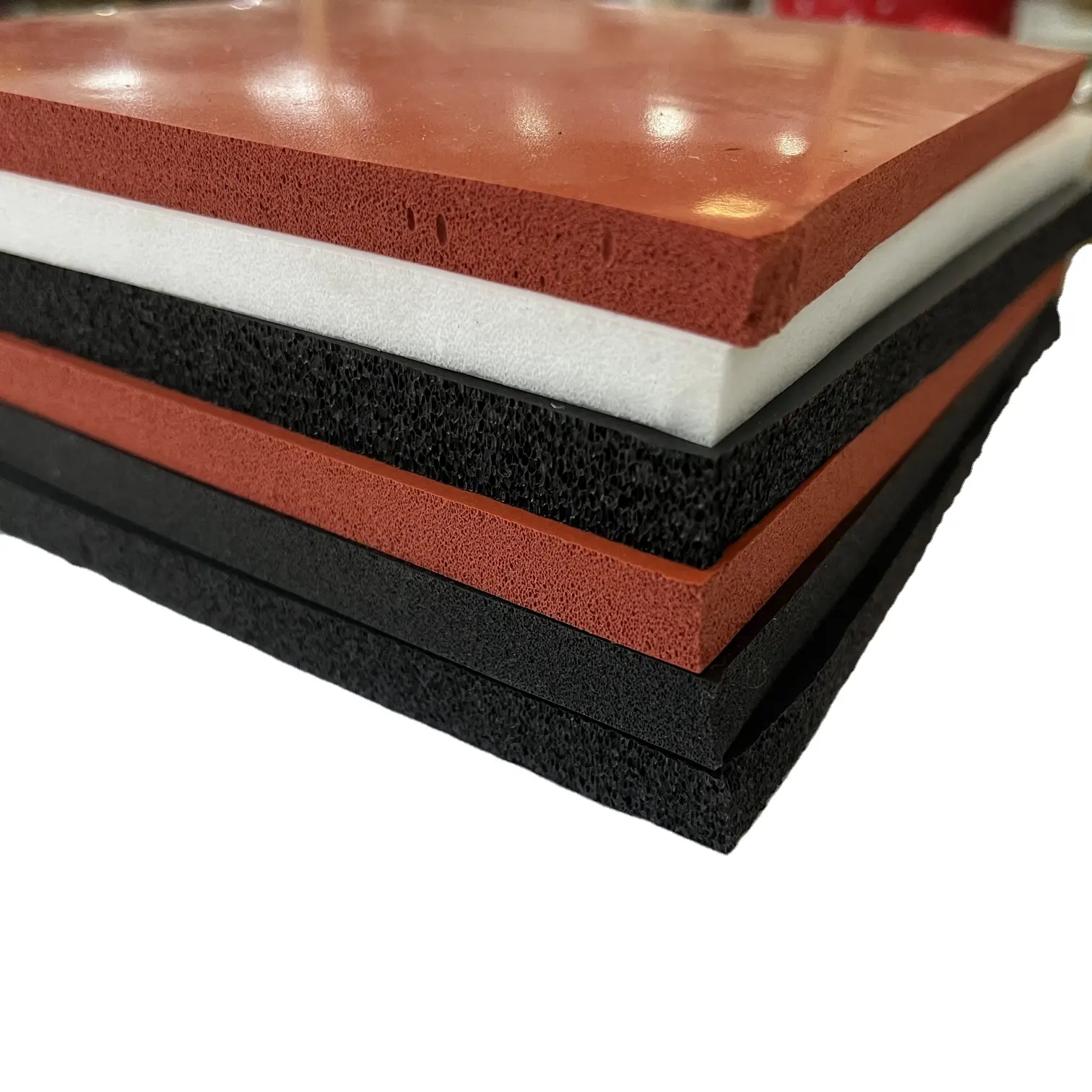

- Категория: Silicone Rubber >>>

- Поставщик: ACME,RAPID,PROTOTYPING,LTD

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.14 $* | 0.7 $* |

| Aug-19-2025 | 0.73 $* | 0.47 $* |

| Jul-19-2025 | 0.13 $* | 0.82 $* |

| Jun-19-2025 | 0.34 $* | 0.29 $* |

| May-19-2025 | 0.60 $* | 0.99 $* |

| Apr-19-2025 | 0.36 $* | 0.12 $* |

| Mar-19-2025 | 0.15 $* | 0.29 $* |

| Feb-19-2025 | 0.38 $* | 0.37 $* |

| Jan-19-2025 | 0.91 $* | 0.30 $* |

Характеристики

Products Description

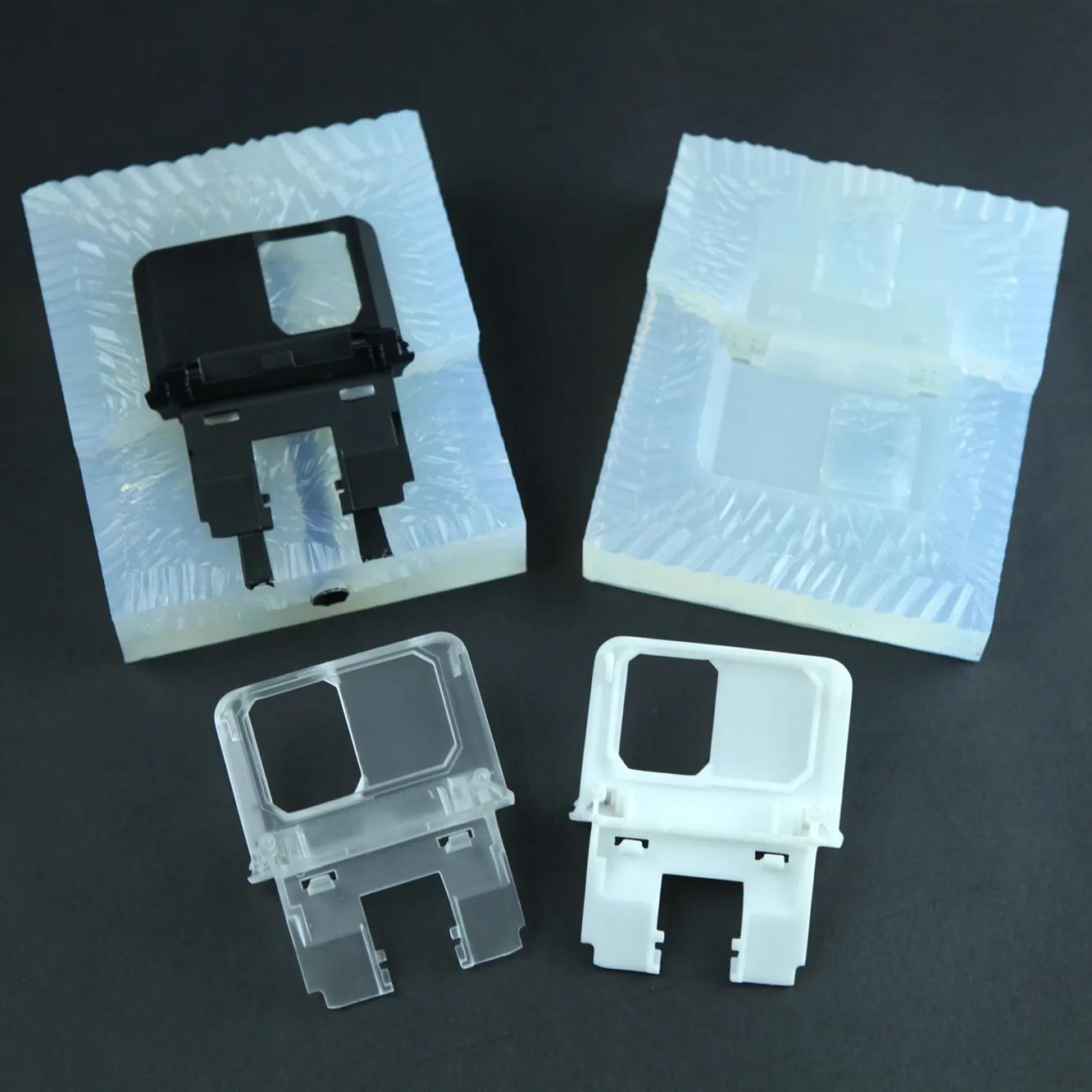

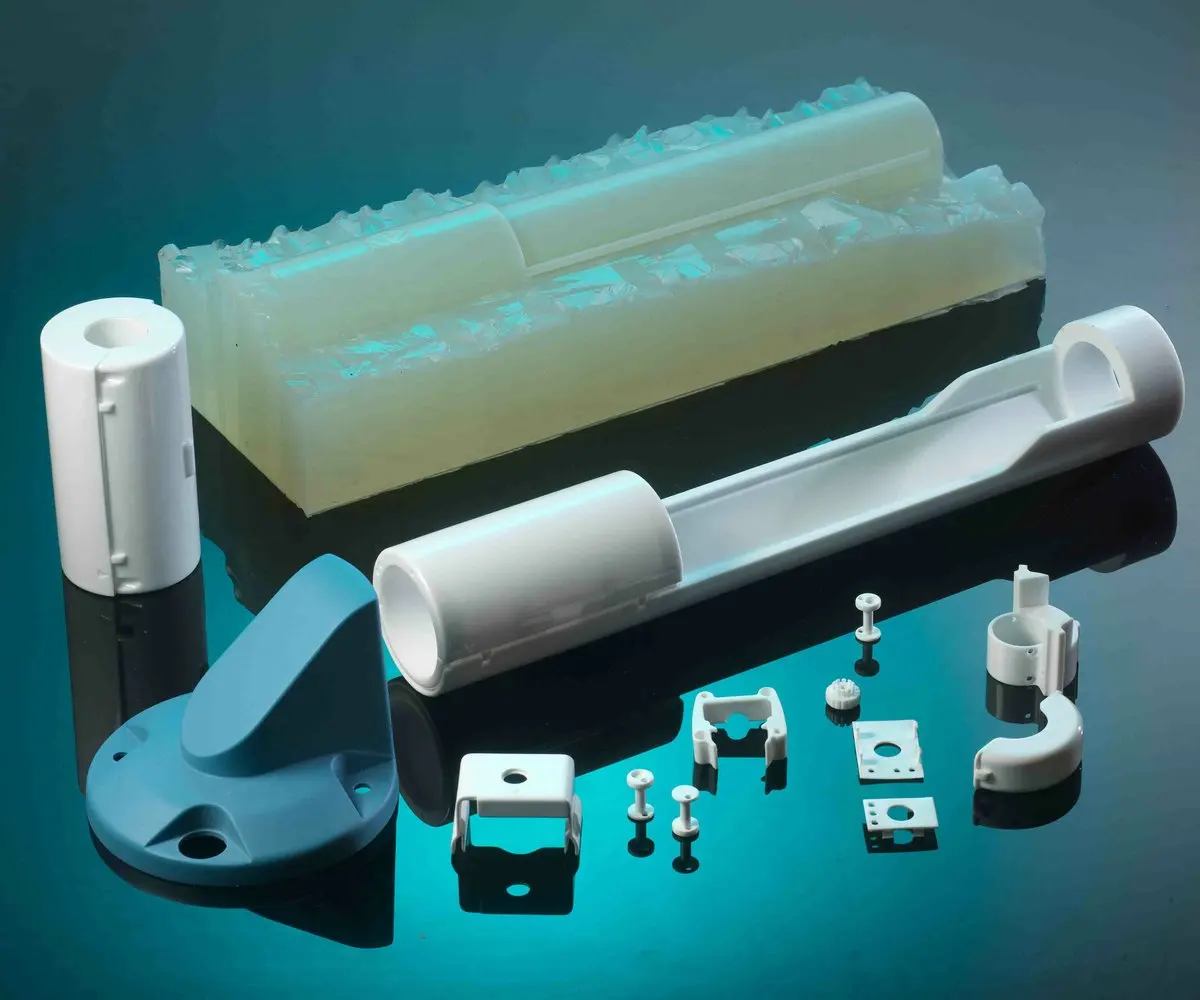

Name | Professional Plastic Injection Mould and Injection Molding Manufacturer |

Mold Material | P20/718/738/NAK80/S136 etc |

Mold life | 100k- 500k Shots(Mold life is different under different circumstance) |

Mold Cavity | Single Cavityand Multi-cavity |

Mold precision | +-0.01mm |

Runner System | Hot runner and cold runner |

Mold Base | Hasco Standard. European Standard. World Standard |

Mold Base Material | LKM, FUTA, HASCO, DME...etc. Or as per Customer's Requirment. |

Files Format | STEP/STL/IGS/JPG/PDF etc |

Product Material | PLASTIC: ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT etc |

Surface Treatment | Polish, Painting, Plating, Printing, Smooth etc |

Making Process | Mold+Injection + Assembly + Packaging |

Equipment | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available |

Quality Assurance | IS09001:2008 |

1.From the time a customer order is received, our experienced customer service representatives process the order into our computer system to determine the scheduled shipping date.

2. Skilled, experienced staff using the latest production equipment to ensure your product meets all your custom needs.

Mold Process

Step 1. Product DFM

Step 2. Mold Design

Step 3. Prepare Material

Step 4. 3D Printing Sample

Step 5. Mke mold

Step 6. Mold Fitting

Step 7. Mold Trail

Step 8. Sample Injection

Step 9. No problem

Step 10. Mass production

Step 11. Product quality inspection

Step 2. Mold Design

Step 3. Prepare Material

Step 4. 3D Printing Sample

Step 5. Mke mold

Step 6. Mold Fitting

Step 7. Mold Trail

Step 8. Sample Injection

Step 9. No problem

Step 10. Mass production

Step 11. Product quality inspection

ACME SOLUTION

We specialize in rapid tooling, injection mold and CNC machining in high quality. Acme is the real-world solutions for Rapid product development. Acme based in Shenzhen, China, founded in 2001,over 20 years experience. We serve customers all over the world. Customization product including Medical device, digital products, silicone rubber products,turning-lathe products,automobile parts. Especially in use special material with small-batch products.We offer high quality service in low price. We will take much time to understand your product development requirements and recommend you the better process, our goal is to help you produce a better product.

More than 20 years experiences engineer

Jacky Chen

Young engineer and manager

Edison Chen

ACME SOLUTION STAFF |

ACME SOLUTION ADVANTAGES |

1. 24 Hours Online Service

2. Hi-Q

3. Stable supply

4. Great team

5.Yield capacity

6. First-class service

7.Quality control

8. Meticulous Packing

9. Prompt delivery

3. Stable supply

4. Great team

5.Yield capacity

6. First-class service

7.Quality control

8. Meticulous Packing

9. Prompt delivery

ACME SOLUTION DEPARTMENT OFFICE |

Mold Making Process

Packing

Customer Photos

Buyer Review

FQA

1. Where can I get specific product&price information?

Email: joanna@acme-rp.com ,or click the bottom: Send your message to this supplier. Hope this will help you. Any question will be appreciated.

2. What kind of production service do you provide?

Mould making, die casting, CNC machining, stamping, Plastics injection moulding, simple assembly and various metal surface treatment.

Email: joanna@acme-rp.com ,or click the bottom: Send your message to this supplier. Hope this will help you. Any question will be appreciated.

2. What kind of production service do you provide?

Mould making, die casting, CNC machining, stamping, Plastics injection moulding, simple assembly and various metal surface treatment.

3. Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in Shenzhen, China.

4.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

5. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

6.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

7. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

8. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

9. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

10. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

4.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

5. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

6.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

7. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

8. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

9. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

10. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Похожие товары

Силиконовая шпатлевка для изготовления пресс-форм

US $20.00-$25.00

Прозрачная силиконовая резиновая пленка Shenzhen

US $2.50-$13.00