FEIHONG CNC профессиональный производитель оптовая продажа сварочный аппарат

- Категория: Welding Equipment >>>

- Поставщик: Shandong,Feihong,Engineering,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 142800.54 $* | 149940.28 $* |

| Aug-18-2025 | 141600.30 $* | 148680.59 $* |

| Jul-18-2025 | 118800.11 $* | 124740.87 $* |

| Jun-18-2025 | 139200.74 $* | 146160.47 $* |

| May-18-2025 | 121200.77 $* | 127260.5 $* |

| Apr-18-2025 | 136800.61 $* | 143640.39 $* |

| Mar-18-2025 | 135600.23 $* | 142380.30 $* |

| Feb-18-2025 | 134400.65 $* | 141120.26 $* |

| Jan-18-2025 | 133200.49 $* | 139860.9 $* |

Характеристики

Product Description

* Introduction

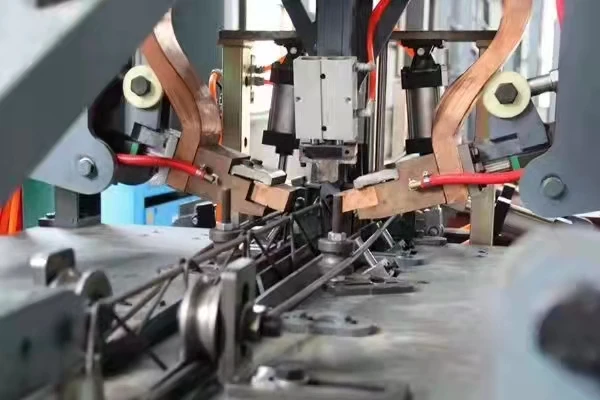

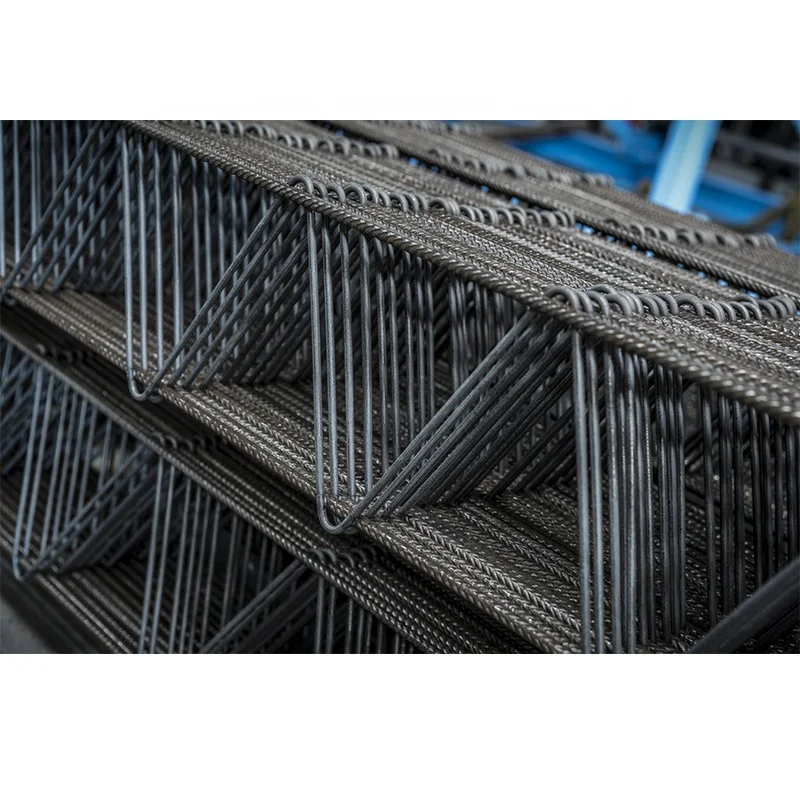

Lattice Girder production line is a fully automated production line that sets the wire of raw material, straightening steel bar, bending forming, automatic welding, fixed length cutting and numerical control delivery of finished products.Lattice Girder production line is widely used in the production of double block sleeper truss and the production of floor slab truss on high speed railway.

The product alias: triangular beam truss, sleeper truss, double block sleeper truss, steel bar truss, composite floor board, composite floor, truss, truss, truss welding, truss welding machine, automatic truss welding machine, truss forming, truss processing, steel truss, steel truss processing equipment, steel truss welding equipment. Steel truss forming equipment and truss welding machine .

----It can produce steel trusses for floor decks and PC steel trusses for prefabricated buildings.

---The web bars are bent by cylinders, so it is convenient and time-saving to adjust the truss specifications.

---The total welding power is 300KVA, and the required external transformer power is small.

---The pitch of the web rods after bending is adjustable from 190-210mm, and can be cut to any length, avoiding the waste of steel bars.

---Welding transformers are produced by Japanese technology, with good welding performance and durability.

---The welding host has a large space, which facilitates the adjustment of the truss when changing specifications and the maintenance of the equipment.

---The cut-off part is mechanically driven. Compared with hydraulic cut-off, it has no noise and saves electricity.

---The control program has been used on more than 200 devices for many years, and the program is stable and reliable.---T----his equipment has simple structure, strong practicability and convenient maintenance.

---The web bars are bent by cylinders, so it is convenient and time-saving to adjust the truss specifications.

---The total welding power is 300KVA, and the required external transformer power is small.

---The pitch of the web rods after bending is adjustable from 190-210mm, and can be cut to any length, avoiding the waste of steel bars.

---Welding transformers are produced by Japanese technology, with good welding performance and durability.

---The welding host has a large space, which facilitates the adjustment of the truss when changing specifications and the maintenance of the equipment.

---The cut-off part is mechanically driven. Compared with hydraulic cut-off, it has no noise and saves electricity.

---The control program has been used on more than 200 devices for many years, and the program is stable and reliable.---T----his equipment has simple structure, strong practicability and convenient maintenance.

---The stepping mechanism is controlled by a servo motor with high accuracy.

---Automatic control of the pay-off mechanism to prevent chaotic lines.

---Intelligent fault identification and alarm system, easy to maintain.

---All imported electrical components are used, and the electrical control is stable.

---Automatic control of the pay-off mechanism to prevent chaotic lines.

---Intelligent fault identification and alarm system, easy to maintain.

---All imported electrical components are used, and the electrical control is stable.

Model | FHLG350 | ||||||

voltage | 380V 50HZ | ||||||

Electricity demand | 250KVA | ||||||

Welding transformer | 2*150KVA(Intermittent work) | ||||||

Shearing motor power | 11KW+11KW(Intermittent work) | ||||||

Side rib motor forming power | 11KW+11KW | ||||||

Other power | 30KW | ||||||

Girder Height | 50-300mm | ||||||

Girder width | 60-100mm | ||||||

Upper thread | 6-14mm | ||||||

Lower thread | 6-14mm | ||||||

Bending side stirrup diameter | 4-8mm | ||||||

Max.working speed | 9-12m/min | ||||||

Step spacing | 190-210mm(Adjustable) | ||||||

Girder length | 0.4-99M | ||||||

Cutting method | Mechanical | ||||||

Transmission method | AC servo motor | ||||||

Welding method | mechanical pneumatic | ||||||

weight | About 18T | ||||||

Grouped equipment

Chiller

Air compressor

Rebar Butt Welding Machine

Finished Product Display:

Package&Shipment:

Company Profile:

Customer Photos

Certification

Contact