HB-AC700 модель полностью автоматическая высокоскоростная нетканый жилет мешок

- Категория: Packaging Material Making Machine >>>

- Поставщик: Wenzhou,Haixin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 28560.83 $* | 29988.60 $* |

| Aug-17-2025 | 28320.32 $* | 29736.23 $* |

| Jul-17-2025 | 23760.86 $* | 24948.83 $* |

| Jun-17-2025 | 27840.99 $* | 29232.70 $* |

| May-17-2025 | 24240.70 $* | 25452.0 $* |

| Apr-17-2025 | 27360.76 $* | 28728.59 $* |

| Mar-17-2025 | 27120.34 $* | 28476.91 $* |

| Feb-17-2025 | 26880.37 $* | 28224.76 $* |

| Jan-17-2025 | 26640.7 $* | 27972.99 $* |

Характеристики

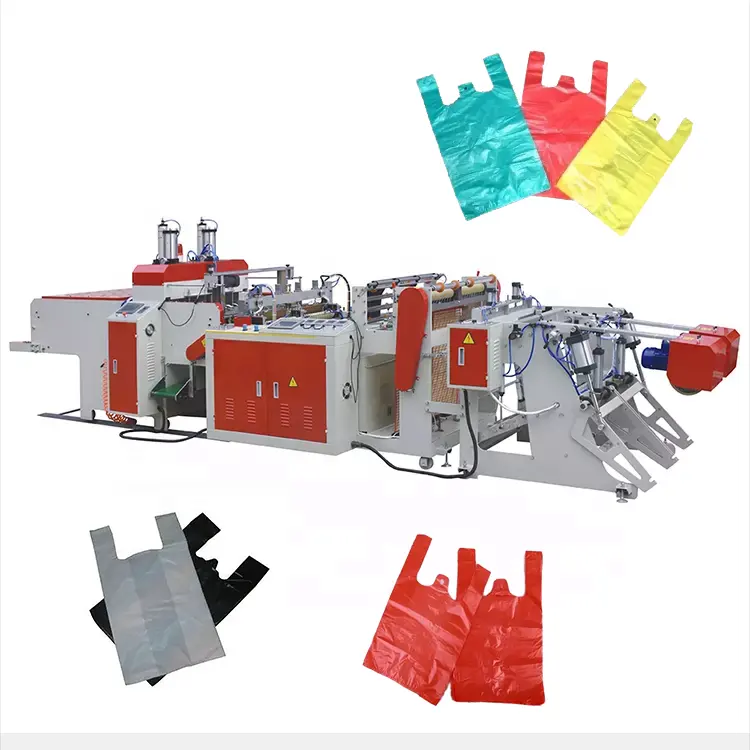

HB-AC700 Non woven T shirt bag making machine

Performance and characteristics:

1. This machine is suitable for non-woven fabrics, and can process a variety of different specifications and different shapes of non-woven t-shirt bags, flat bags, drawstring bags, etc. The machine integrates electromechanics and uses LCD touch screen operation. Equipped with step-by-step fixed length, photoelectric tracking, computer automatic positioning, computer automatic edge correction, accurate and stable. Automatic counting can set counting alarm, automatic punching and other industrial control devices, so that the finished product can be sealed tightly and cut beautifully. High-speed and high-efficiency, it is a high-quality environmentally friendly bag-making equipment that you can use with confidence.

2. Process flow: roll material---folding---setting---punching---paying-off---heat sealing---folding in half---heat sealing---cutting---collecting finished products.

3. Main technical parameters:

Unit | name | SPECIFICATION |

Model | HBL-Ac700Non woven T shirt bag making machine | |

Raw material rolls witth | 50-1250mm | |

speed | 20-120pcs/min | |

Bag length | 200-600mm | |

Bag width | 100-800mm | |

Bag thickness | 30-120g | |

voltage | 220v,380v | |

power | 10-18KW | |

size | 10300*2000*2100mm | |

Whole machine | Unwinding unit | 1sets |

Flat folding traction unit | 1sets | |

Vertical folding unit | 1sets | |

Unwind unit | Unwinding form | Magnetic powder tension control |

Paper tube clamping device | Air shaft φ3″(φ76mm) | |

Unwinding diameter | φ1000mm | |

Control part and discharge part | Correction device | automatic correction system control |

Automatic shutdown without material | Automatic light control tracking | |

Feeding plate | Stainless steel plate (triangle) | |

Whole machine control system | Non-woven fabric (two-drive) bag making machine system | |

Ultrasound system | Edge banding 153mm 4 pcs Flat fold 70mm 2 pcs Vest 70mm 1pc | |

Temperature control system | China 1 Sets | |

Operation method | Touch screen Siemens PLC and Screen | |

Relay | Omron | |

Pneumatic Components | AirTAC | |

Commonly used electrical appliance brands | Temperature indicator | China |

Common electrical components/switches | Chint | |

Frequency converter | Dvorak Japan | |

Inverter motor | Loboao Shanhgai | |

Ironing the display | Taiwan Velon (LCD touch screen) built-in PLC | |

Bearing | Produced by Harbin Sino-Japanese Joint Venture Group |

Installation

We disassemble the machine into five parts and put it into the container, like below pictures

We write a number on each part,The guest receives the machine, just tighten the machine screws according to the position.--we will provide tool box

We will also set up an after-sales group on WhatsApp or WeChat, which has our after-sales maintenance technical master, and guests can ask any questions in the group.