JBD Высококачественная BMS 7 ~ 20S 200A 300A Lifepo4 система управления литий-ионными аккумуляторами с реле того же порта UART

- Категория: PCB & PCBA >>>

- Поставщик: Shenzhen,Yizhi,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.19 $* | 0.83 $* |

| Aug-17-2025 | 0.83 $* | 0.8 $* |

| Jul-17-2025 | 0.17 $* | 0.54 $* |

| Jun-17-2025 | 0.59 $* | 0.46 $* |

| May-17-2025 | 0.34 $* | 0.22 $* |

| Apr-17-2025 | 0.59 $* | 0.94 $* |

| Mar-17-2025 | 0.68 $* | 0.27 $* |

| Feb-17-2025 | 0.91 $* | 0.75 $* |

| Jan-17-2025 | 0.99 $* | 0.23 $* |

Характеристики

Company Profile

Products Description

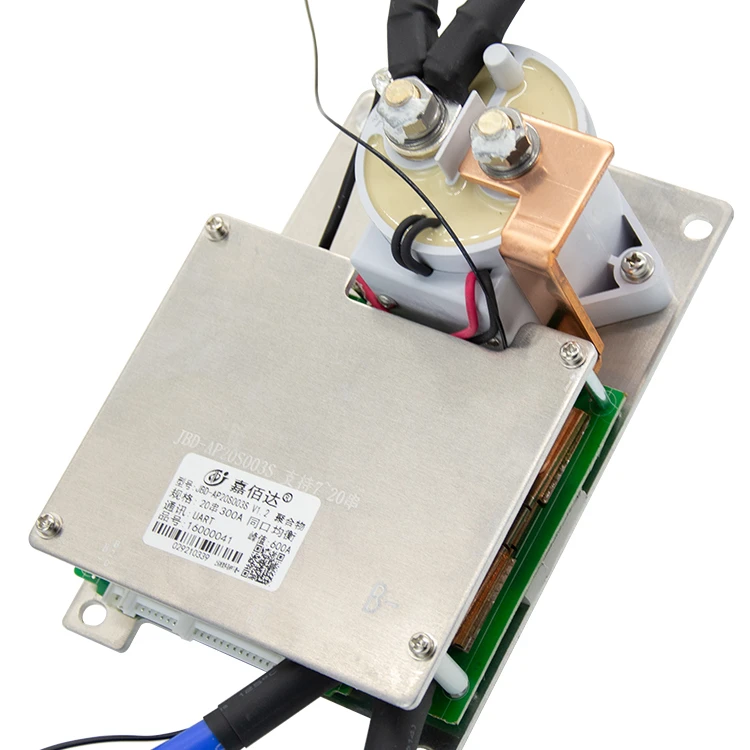

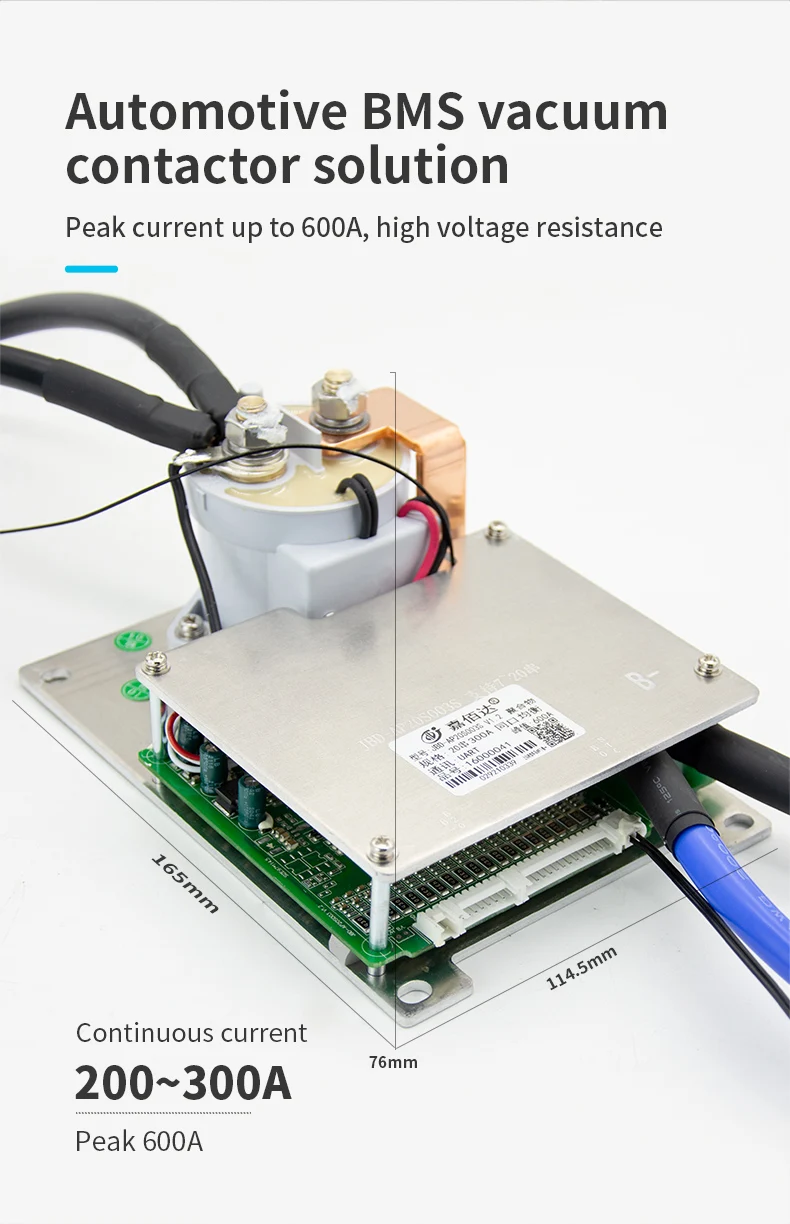

JBD-AP20S003S

JBD-AP20S003S is specially designed for 7 ~ 20 series battery packs of power batteries, electric bicycles, motorcycles and other products; it can be applied to lithium batteries with different chemical properties, such as lithium ion, lithium polymer, lithium iron phosphate, etc. The protection board has strong load carrying capacity and the maximum continuous discharge current can reach 300A.

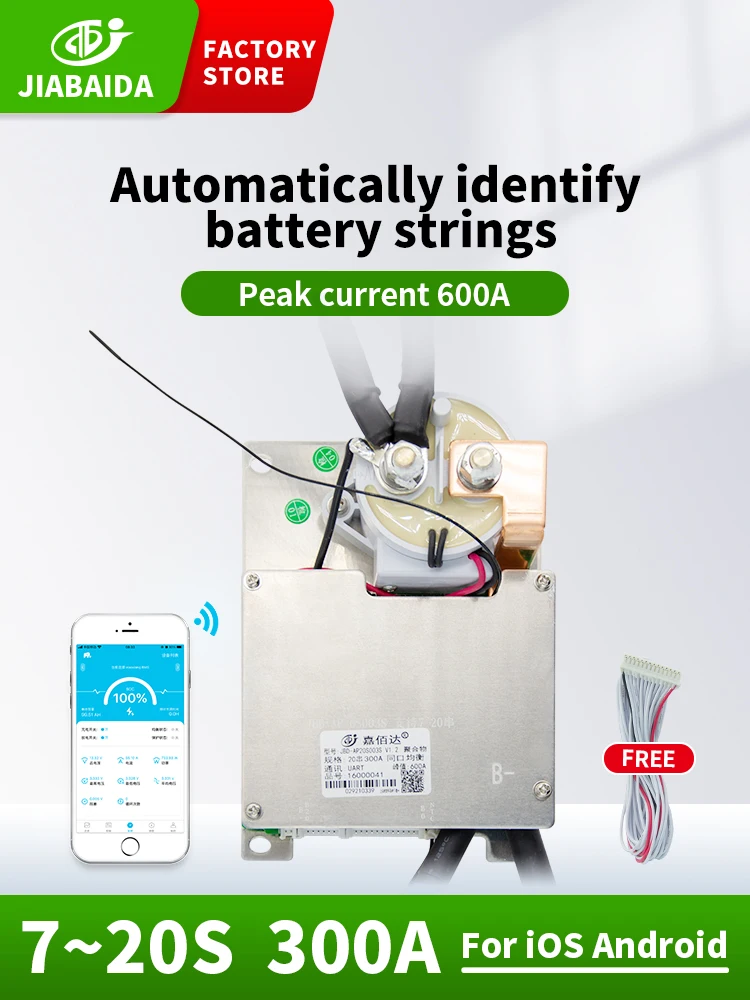

● 7-20 cell series protection, and automatically recognize the number of battery strings

● The car gauge level simulates the front chip, the voltage acquisition precision is high;more secure and reliable.

● Various protection functions for charging and discharging

● Power switch for relay, high voltage, more reliable.

● Accurate SOC calculation with automatic SOC learning function

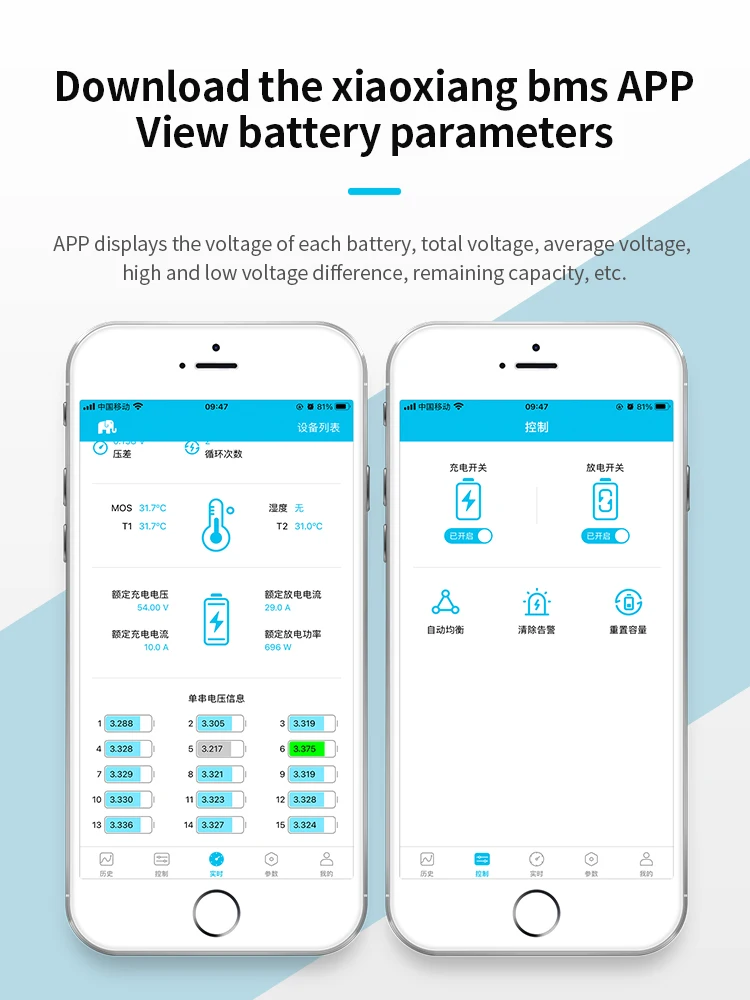

● Optional RS485 communication function can read all battery data in real time and upgrade online.

● Optional CAN communication function

● Reserve switch control protection panel output.There is a discharge switch to have a pre-charge function to prevent lighting

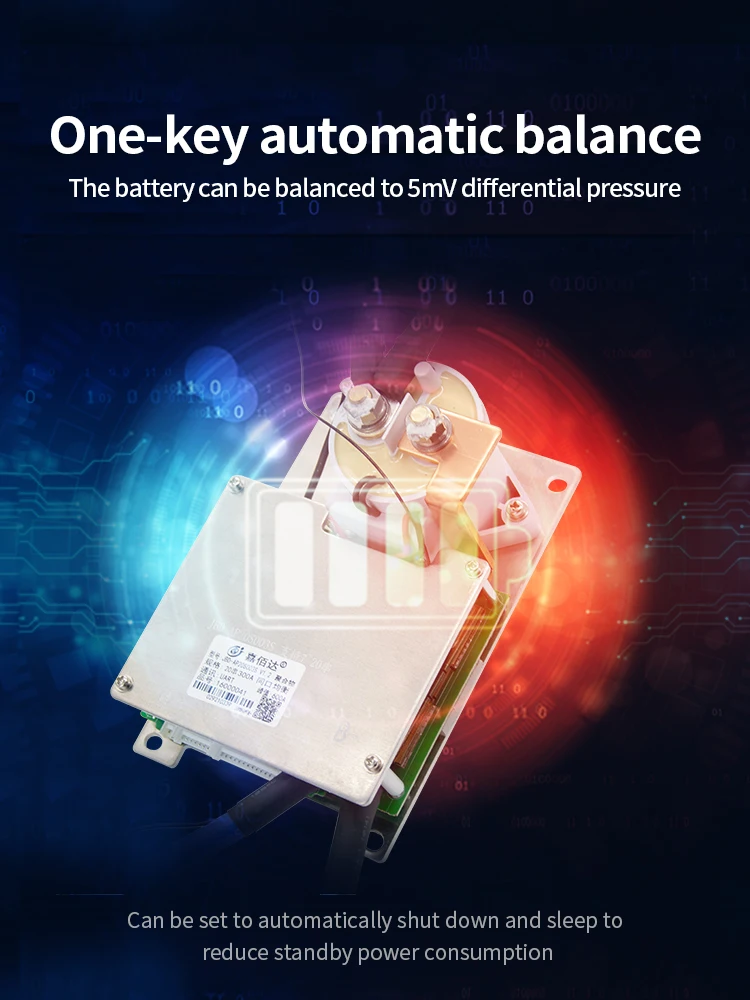

● When the standing time reaches the set value (page switching time for parameter setting), the machine will automatically shut down and sleep to reduce standby power consumption.

● Support series connection, but the total number of series after series connection is less than or equal to 32 series

● Parallel use of battery packs is not supported (battery packs are directly connected in parallel, and there is a problem of large current discharge of high-voltage battery packs to low-voltage battery packs)

● 7-20 cell series protection, and automatically recognize the number of battery strings

● The car gauge level simulates the front chip, the voltage acquisition precision is high;more secure and reliable.

● Various protection functions for charging and discharging

● Power switch for relay, high voltage, more reliable.

● Accurate SOC calculation with automatic SOC learning function

● Optional RS485 communication function can read all battery data in real time and upgrade online.

● Optional CAN communication function

● Reserve switch control protection panel output.There is a discharge switch to have a pre-charge function to prevent lighting

● When the standing time reaches the set value (page switching time for parameter setting), the machine will automatically shut down and sleep to reduce standby power consumption.

● Support series connection, but the total number of series after series connection is less than or equal to 32 series

● Parallel use of battery packs is not supported (battery packs are directly connected in parallel, and there is a problem of large current discharge of high-voltage battery packs to low-voltage battery packs)

Detailed Images

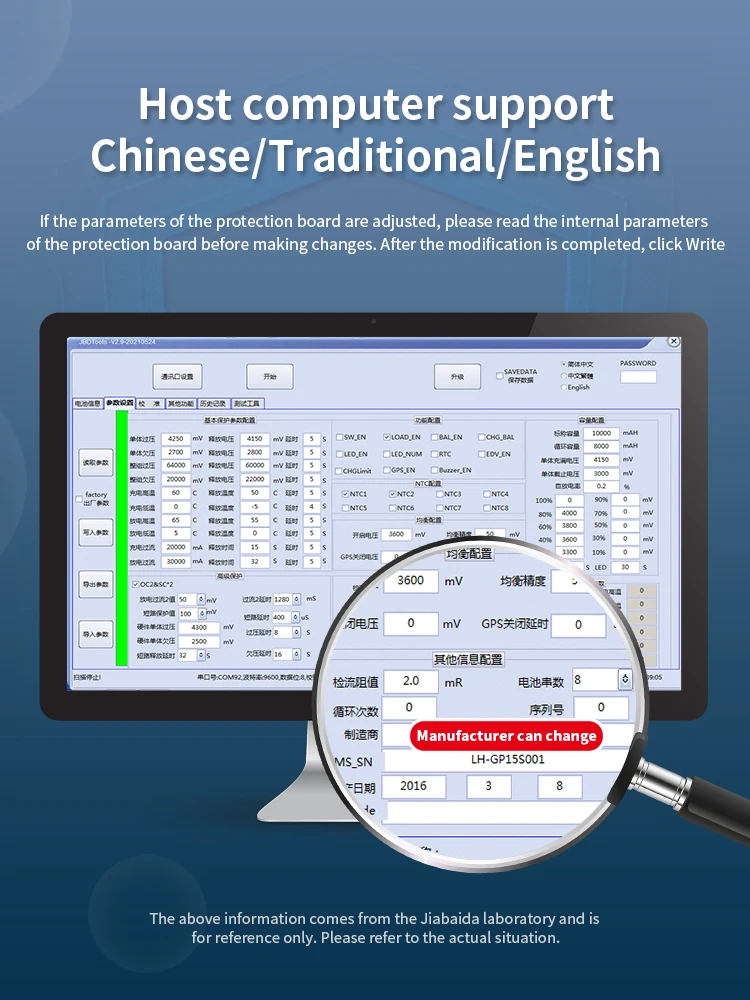

Operating voltage range | 60-90V |

Operating current (MAX) | 200A 300A |

Over-charge protection voltage | 4.25±0.03V |

Over-discharge protection voltage | 2.8±0.1V |

Balanced turn-on voltage | 3.6±0.03V |

Charging over current protection value | 270-330A |

High temperature protection value of charging | 65±3℃ |

High temperature protection value of discharge | 75±3℃ |

Internal resistance | <10mΩ |

Protection function description

Overcharge protection: When the battery is under the charging state, the voltage keeps going up. When the protection board detects that the voltage of any cell is higher than the overcharge protection value, the protection board will start timing immediately. When the time reaches the overcharge protection delay, the protection board will turn off the charging MOS tube, at that time, it cannot be charged.

Overcharge protection recovery: After the overvoltage protection appears on the protection board, the battery voltage will going down under the static or discharge state of the battery. When the protection board detects that each voltage is lower than the recovery voltage of the overcharge protection, the protection board will output a signal and turn on the charging MOS tube to charge.

Over-discharge protection: When the battery is under the discharge state, the voltage keeps going down. When the protection board detects that the voltage of any cell is lower than the overcharge protection value, the protection board will start timing immediately. When the time reaches the over discharge protection delay, the output signal of the protection board will turn off the discharge MOS tube, the load lock circuit will work, but, it cannot discharge at this time.

Over discharge protection recovery: After the over discharge protection appears on the protection board, the battery voltage will going up under the static or discharge state of the battery. When the protection board detects that each voltage is higher than the recovery voltage of the over discharge protection. At this time, disconnect the load or charge, the protection board will output a signal and turn on the charging MOS tube to charge.

Overcurrent protection: When the battery is under the static or discharge state, the current suddenly increases. When the protection board detects that the current reaches the overcurrent protection value, the protection board will start timing at that time. When the current duration in the circuit reaches the overcurrent protection delay time, the output signal of the protection board will turn off the discharge MOS tube, and the load lock circuit will work. At this time, the discharge cannot be conducted.

Overcurrent protection recovery: After the discharge overcurrent protection appears on the protection board, the discharge MOS tube is turned off, and the current in the loop becomes 0. At this time, the load is disconnected or charged, the output signal of the protection board will turn on the discharge MOS tube to discharge.

Overcharge protection recovery: After the overvoltage protection appears on the protection board, the battery voltage will going down under the static or discharge state of the battery. When the protection board detects that each voltage is lower than the recovery voltage of the overcharge protection, the protection board will output a signal and turn on the charging MOS tube to charge.

Over-discharge protection: When the battery is under the discharge state, the voltage keeps going down. When the protection board detects that the voltage of any cell is lower than the overcharge protection value, the protection board will start timing immediately. When the time reaches the over discharge protection delay, the output signal of the protection board will turn off the discharge MOS tube, the load lock circuit will work, but, it cannot discharge at this time.

Over discharge protection recovery: After the over discharge protection appears on the protection board, the battery voltage will going up under the static or discharge state of the battery. When the protection board detects that each voltage is higher than the recovery voltage of the over discharge protection. At this time, disconnect the load or charge, the protection board will output a signal and turn on the charging MOS tube to charge.

Overcurrent protection: When the battery is under the static or discharge state, the current suddenly increases. When the protection board detects that the current reaches the overcurrent protection value, the protection board will start timing at that time. When the current duration in the circuit reaches the overcurrent protection delay time, the output signal of the protection board will turn off the discharge MOS tube, and the load lock circuit will work. At this time, the discharge cannot be conducted.

Overcurrent protection recovery: After the discharge overcurrent protection appears on the protection board, the discharge MOS tube is turned off, and the current in the loop becomes 0. At this time, the load is disconnected or charged, the output signal of the protection board will turn on the discharge MOS tube to discharge.

Customers Satisfaction

Details Images

matters need attention.

Please note:When assembling the wiring, weld the cable and the cell correctly, connect the B- of the PCM with the total negative pole of the cell, and then insert the cable into the needle base on the PCM. (Note: different connection modes for different strings, and different connection modes for the same port)

Certifications

FAQ

1. What type of charger should I choose?

Lithium battery must choose specific charger, do not use Charger for Leadacid battery, for leadacid charger may have MOS with high pressure breakdown protection, which will not protect of BMS over charge. Life Po4 battery charger voltage=battery string No.X3.6V, while Li-ion battery charger voltage=Battery string No.X4.2V.

2.The relationship between Battery capacity and BMS current?

There is no direct relationship between Battery capacity and BMS current, big capacity doesn`t mean a big battery, but rely on continue current, that is to say if your engine is powerful, your should choose high current of BMS, it is not relied on batterycapacity.

3.Whether my BMS damaged?

If you want to judge if the BMS is damaged, please take the folowing steps, to test if each cell voltage is the same with

voltmeter? if the cell voltage difference is over 1.0V, the fault is displayed that it cannot run far, no power supply at the

start range, short charge time, all these issues are almost caused by battery cells, if BMS damaged is displyed as no charge, no discharge, no discharge while the battery has voltage.

Lithium battery must choose specific charger, do not use Charger for Leadacid battery, for leadacid charger may have MOS with high pressure breakdown protection, which will not protect of BMS over charge. Life Po4 battery charger voltage=battery string No.X3.6V, while Li-ion battery charger voltage=Battery string No.X4.2V.

2.The relationship between Battery capacity and BMS current?

There is no direct relationship between Battery capacity and BMS current, big capacity doesn`t mean a big battery, but rely on continue current, that is to say if your engine is powerful, your should choose high current of BMS, it is not relied on batterycapacity.

3.Whether my BMS damaged?

If you want to judge if the BMS is damaged, please take the folowing steps, to test if each cell voltage is the same with

voltmeter? if the cell voltage difference is over 1.0V, the fault is displayed that it cannot run far, no power supply at the

start range, short charge time, all these issues are almost caused by battery cells, if BMS damaged is displyed as no charge, no discharge, no discharge while the battery has voltage.

Recommend Products