Станок для сварки алюминиевых проводов Tesla ультразвуковой сварочный аппарат 18650 аккумуляторов

- Категория: Spot Welders >>>

- Поставщик: Guangdong,Songke,Lead,Intelligent,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.87 $* | 0.53 $* |

| Aug-16-2025 | 0.49 $* | 0.33 $* |

| Jul-16-2025 | 0.89 $* | 0.61 $* |

| Jun-16-2025 | 0.40 $* | 0.42 $* |

| May-16-2025 | 0.51 $* | 0.65 $* |

| Apr-16-2025 | 0.17 $* | 0.61 $* |

| Mar-16-2025 | 0.97 $* | 0.0 $* |

| Feb-16-2025 | 0.41 $* | 0.94 $* |

| Jan-16-2025 | 0.72 $* | 0.0 $* |

Характеристики

Product Overview

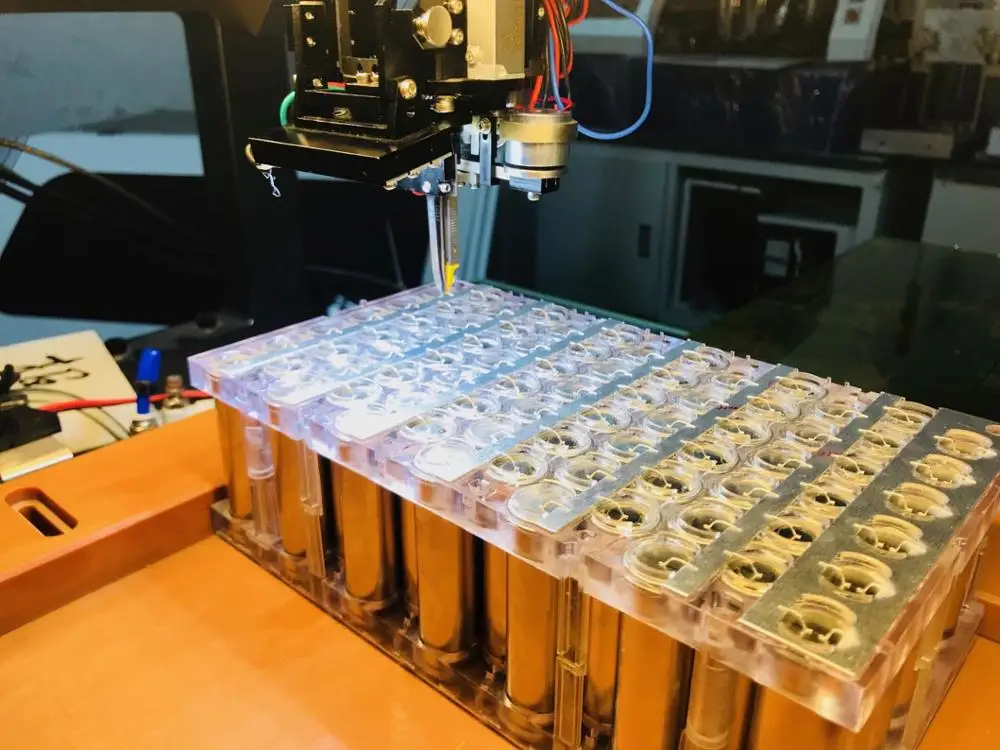

\u007F21700 Lithium battery pack ultrasonic aluminum wire bonding machine For 26650/32650 battery welding

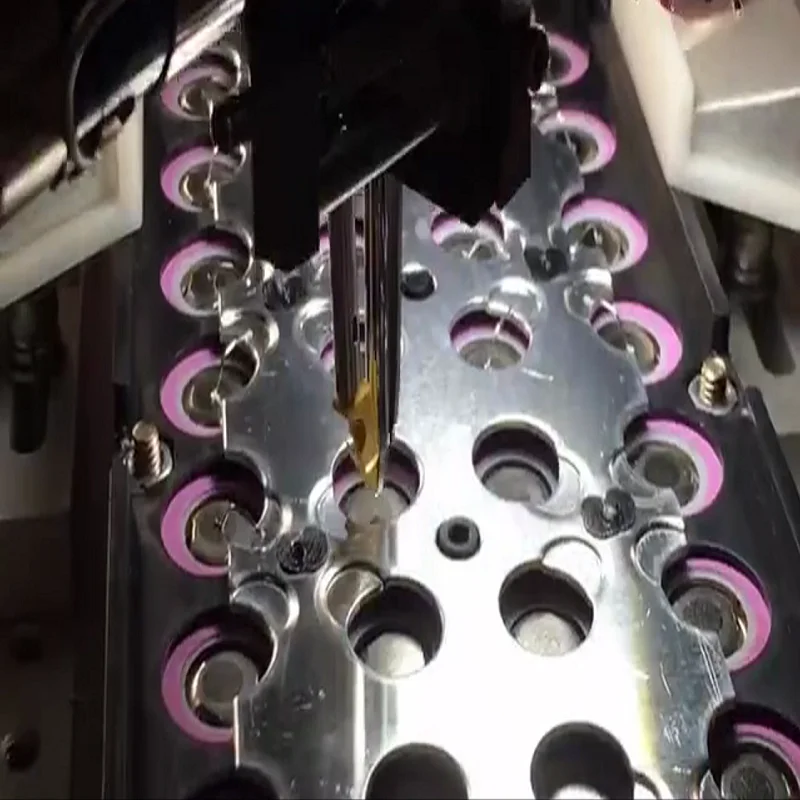

The basic working principle of the equipment:

After the module assembly process is completed, the equipment is used to automatically load the system,

and then sent to the welding area through the automatic feeding system. The welding head system performs ultrasonic welding

according to the setted welding parameters and position. After the welding is completed, the module is sent to the designated

position automaticly

by the feeding system, and the equipment operator takes out the welded module and sends it to the next production process.

Equipment application:

Mainly used for electrical connection of power battery module cell and busbar,Applicable aluminum wire diameter range is 125~500um

Equipment Specifications

Welding area: 650 mm in X direction * 650 mm effective stroke in Y direction (standard)

Z axis: maximum travel distance 60 mm, 1.25 μm resolution

Rotary axis: ±220 degrees, 0.08 degree resolution

Power requirements: 220V AC, 50/60 Hz

Power consumption: 3000W

Compressed air: 0.5pla

Display: 17-inch color plane display

Working surface height: 1150 mm from the ground

Occupied size: 1300 mm long; 1300 mm wide: 1650 mm high (without warning lights)

Net weight: 500 kg

Heavy wire horn: Rotary, standard front cutter

Transducer: Standard 60KHz, other frequencies can be manufactured according to customers'

requirements

Welding pressure: 50----1500 grams

Feed wire system: Motor control wire feeder with optical encoder

Lack of wire detection: wire feeding detection

Maximum arc height: 40 mm

Minimum wire length detection: 2mm feed wire

Spool size: 50---120 mm OD; 22---45 mm width; 10---11 mm ID

Image recognition:/optics/lighting

Visual System: XK Image Recognition System

Communication: IO communication,

After the module assembly process is completed, the equipment is used to automatically load the system,

and then sent to the welding area through the automatic feeding system. The welding head system performs ultrasonic welding

according to the setted welding parameters and position. After the welding is completed, the module is sent to the designated

position automaticly

by the feeding system, and the equipment operator takes out the welded module and sends it to the next production process.

Equipment application:

Mainly used for electrical connection of power battery module cell and busbar,Applicable aluminum wire diameter range is 125~500um

Equipment Specifications

Welding area: 650 mm in X direction * 650 mm effective stroke in Y direction (standard)

Z axis: maximum travel distance 60 mm, 1.25 μm resolution

Rotary axis: ±220 degrees, 0.08 degree resolution

Power requirements: 220V AC, 50/60 Hz

Power consumption: 3000W

Compressed air: 0.5pla

Display: 17-inch color plane display

Working surface height: 1150 mm from the ground

Occupied size: 1300 mm long; 1300 mm wide: 1650 mm high (without warning lights)

Net weight: 500 kg

Heavy wire horn: Rotary, standard front cutter

Transducer: Standard 60KHz, other frequencies can be manufactured according to customers'

requirements

Welding pressure: 50----1500 grams

Feed wire system: Motor control wire feeder with optical encoder

Lack of wire detection: wire feeding detection

Maximum arc height: 40 mm

Minimum wire length detection: 2mm feed wire

Spool size: 50---120 mm OD; 22---45 mm width; 10---11 mm ID

Image recognition:/optics/lighting

Visual System: XK Image Recognition System

Communication: IO communication,

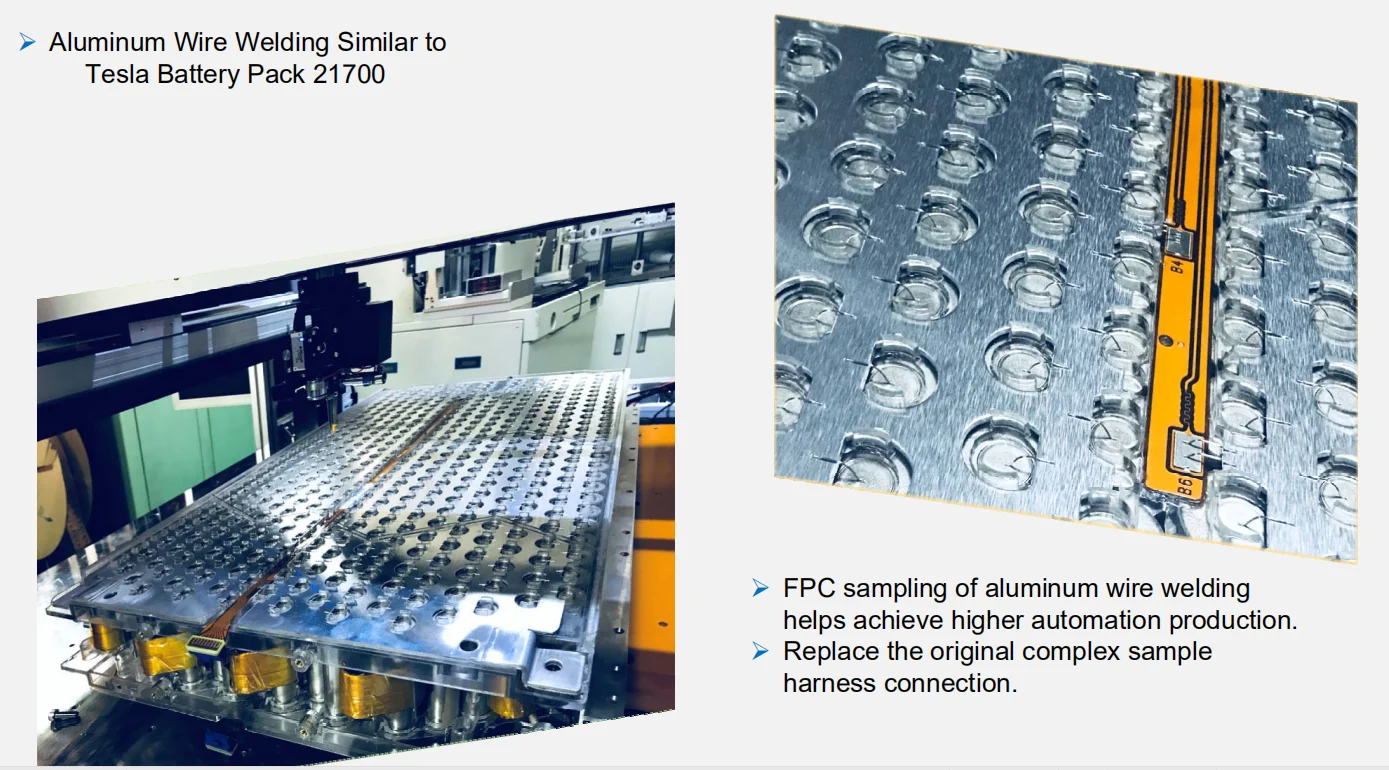

Successful Project

SIMILAR PRODUCTS

FAQ

Q: Are you trading company or manufacturer ?

A: We are a factory and all products are produced, controlled and sold in the factory.

Q: How long is your delivery time?

A: Generally 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:Q: Are you trading company or manufacturer ?

A: We are a factory and all products are produced, controlled and sold in the factory.

Q: How long is your delivery time?

A: Generally 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

A: We are a factory and all products are produced, controlled and sold in the factory.

Q: How long is your delivery time?

A: Generally 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:Q: Are you trading company or manufacturer ?

A: We are a factory and all products are produced, controlled and sold in the factory.

Q: How long is your delivery time?

A: Generally 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Jenny(Sales Manager)

Cel/whatsapp/wechat: +86-18098919495

sales.jxcgroup(@)gmail.com

mask machine :https://www.youtube.com/watch?v=0STw7KfCFz8

battery pack line :https://youtu.be/EgqrT5EA3ag

battery pack line :https://youtu.be/EgqrT5EA3ag