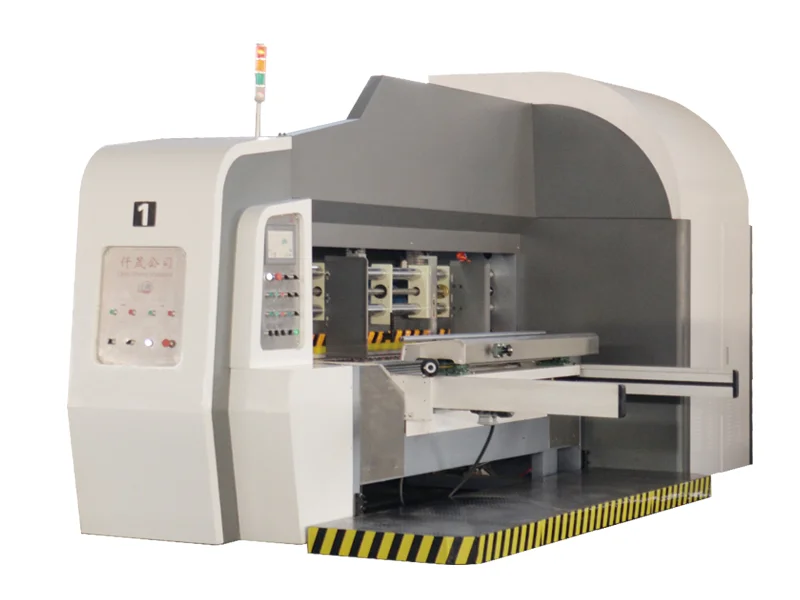

Вакуумный всасывающий трансферный Печатный долбежный высекальный станок с маслом и сушильным

- Категория: Carton Printing Slotting Die-Cutting Machine >>>

- Поставщик: Hebei,Maowei,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.16 $* | 0.12 $* |

| Aug-16-2025 | 0.63 $* | 0.9 $* |

| Jul-16-2025 | 0.16 $* | 0.36 $* |

| Jun-16-2025 | 0.33 $* | 0.47 $* |

| May-16-2025 | 0.71 $* | 0.58 $* |

| Apr-16-2025 | 0.93 $* | 0.45 $* |

| Mar-16-2025 | 0.83 $* | 0.44 $* |

| Feb-16-2025 | 0.67 $* | 0.64 $* |

| Jan-16-2025 | 0.40 $* | 0.73 $* |

Характеристики

Vacuum Suction transfer printing slotting die cutting machine with oil and drying unit

| NO | Name | Unit | Specifications |

| 1 | Machine inside width | mm | 2800 |

| 2 | Design speed | pcs/min | 200 |

| 3 | Economic speed | pcs/min | 30-120 |

| 4 | Max.feed paper size | mm | 1200×2500 |

| 5 | Min.feed paper size | mm | 350×800 |

| 6 | Max.printing size | mm | 1200×2400 |

| 7 | Max.die cutting area | mm | 1200×2400 |

| 8 | Die cutting board thickness | mm | 2-10 |

| 9 | Skip feed paper size | mm | 1300×2500 |

| 10 | Tinted precision | mm | ±0.5 |

| 11 | Standard plate thickness | mm | 7.2 |

| 12 | Adapt to board thickness | mm | 2-10 |

| 13 | Min.slot interval | mm | 300*100*300*100mm |

| 14 | Max. grooving depth | mm | 650 |

| 15 | Axial adjustment of printing drum | mm | ±10 |

| 16 | Gas | miao | 0.3m³ |

| 17 | Water consumption | Day | 1m³ |

| 18 | Total motor power | KW | 200 |

| 19 | Overall dimensions | mm | 19000*5500*3000 |

| 20 | The weight | T | 38 |

Feeder unit(Leading-edge press-free paper feeding)

The electric control machine is attached with alarm bell, and the alarm bell keeps ringing between moving to ensure the safety of operators.

Safety clutch is attached to the drive shaft to avoid damage to the machine due to misaction (the main machine cannot be started when the machine is not locked)

The leading edge feeding mechanism can minimize the clogging phenomenon in the paper feeding process.

Suction fan auxiliary paper feeding, ensure smooth feeding of curved paperboard, air volume can be adjusted according to the size of paperboard, ensure the maximum vacuum adsorption force of paperboard, make the paper feeding more accurate.

Printing unit

Memory return to original printing position function, clean the plate to rotate the printing wheel, automatically record the relative position of various kinds of printing before shutdown.

Printing wheel surface grinding and chrome plating.

Made of high quality steel, surface grinding, hard chrome plating. Static balance correction, smooth operation, suitable for high speed operation.

Roll body horizontal and circumferential direction of the reference engraving line, convenient version.

Worm wheel and worm poleless roll plate shaft. Suitable for standard hanging strip, realize fast version change.

Electric 360° positive and negative adjustment of printing roller, digital automatic display of adjustment.

Foot switch is installed to control the positive and negative rotation of plate loading drum, convenient for plate changing.

Automatic reset function.

Axial electric adjustment of printing roller.

Drying unit(Infrared drying system)

Infrared heating system, rapid and stable temperature rise. The heating power of each group is about 20kW.

Temperature control, segmented heating, saving electric heating power.

Temperature alarm, automatic alarm when the temperature exceeds the standard, safe and reliable.

Strong fan circulation, drying speed more quickly.

The drying box is pneumatic adjustable, convenient to install and replace the lamp, and convenient to adjust the drying effect.

Oil unit

Selection of high quality steel, professional production, dynamic balance test and then fine grinding molding, roller surface engraved with warp and weft lines, more fast plate loading.

The surface is hard chrome plated and durable.

With plate hanging groove, 10mm plate hanging bar with ratchet fixed roll plate shaft, convenient plate hanging use.

Beeline switch is equipped to control the front and reverse of the drum, which is convenient for plate hanging and plate unloading.

Touch screen control or electric control to adjust the printing roller 360 degrees, adopt inverter two-speed control. Man-machine interface setting automatic positioning.

Touch screen control or button control printing roller axial adjustment, maximum movement is ±10mm. Man-machine interface setting automatic positioning.

Drying unit(Infrared drying system)

Infrared heating system, rapid and stable temperature rise. The heating power of each group is about 45kW.

Temperature control, segmented heating, saving electric heating power.

Temperature alarm, automatic alarm when the temperature exceeds the standard, safe and reliable.

Strong fan circulation, drying speed more quickly.

he drying box is pneumatic adjustable, convenient to install and replace the lamp, and convenient to adjust the drying effect.

Rotary die cutting unit with slotting device(Servo-independent drive)

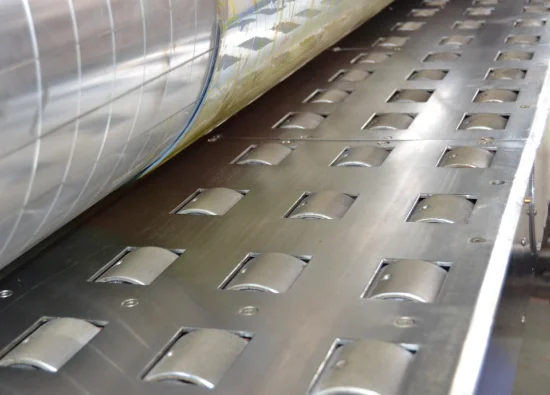

The roller is plated with hard chrome on the surface of high quality steel, and is balanced to increase its stability and reliability

The tool die roll and soft roll adopt international standard size, the diameter of the tool die roll is 360mm, and the diameter of the soft roll is 378mm (the outer diameter of the rubber sleeve is 397 mm), and the suitable template and rubber pad can be purchased anywhere.

The gap between cutter roller and rubber pad roller is manually adjusted.

Die-cutting roll phase using three planets structure, high precision, large bearing capacity, stop, operation can be electric digital 360° adjustment.

When the paper is stopped, the soft roller rises automatically to reduce the wear of the soft roller.

The rubber pad is made of polyurethane felt cover (chuangding brand) produced in Shanghai, which can achieve 100% cutting rate and smooth incision. The replacement order of the rubber pad should be subject to the handling manual of the rubber pad.

The rubber cushion roller adopts mechanical CAM type left and right movement (30mm) device, each knife is in different position, which effectively extends the service life of the felt sleeve.

Stripping stacker machine(optional)