Шлифовальный станок из жесткого

- Категория: Flour Mill >>>

- Поставщик: Zhangjiagang,Sevenstars,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 9401.82 $* | 9871.43 $* |

| Aug-17-2025 | 9322.67 $* | 9788.87 $* |

| Jul-17-2025 | 7821.86 $* | 8212.95 $* |

| Jun-17-2025 | 9164.10 $* | 9622.56 $* |

| May-17-2025 | 7979.86 $* | 8378.25 $* |

| Apr-17-2025 | 9006.67 $* | 9456.58 $* |

| Mar-17-2025 | 8927.78 $* | 9373.98 $* |

| Feb-17-2025 | 8848.79 $* | 9290.68 $* |

| Jan-17-2025 | 8769.4 $* | 9207.44 $* |

Характеристики

Applications of the milling machineplastic grinderplastic pulverizer

SMF series Plastic Milling machine is a prefect machine for processing and grinding thermoplastics material, such as PVC, PE, PP, EVA, PLA, ABS etc, with high output and thin powder.

The SMF series plastic automatic plastic grinding mill is disc-type plastic grinding mill series, which has the advantages of high-yield and low-power.

Characteristics of the milling machineplastic grinderplastic pulverizer

With water cycle and wind cooling, the machine can be applied into processing heat sensitive material.

With the tail-wagging air stream (partly eddy flow) produced by the tail-wagging of the main shaft capstan of the machine, the input tail-wagging materials collide strongly with the board and the cutting blade, and was grinded into powdery (without sieving).

Both the board and the cutting blade are made of abrasion-resistant steel, with excellent performance after heat treatment.

With severeness of framework, the volume of the machine is quite small. If you open door closure, you can maintain it. It is completely airproof and without any dust leakage.

With winding reclaiming equipment, the machine is features by cooling materials evenly, quick cooling and some other characteristics.

Advantages of the milling machineplastic grinderplastic pulverizer

The new disc design is used, high-yield, strong resistance and the life of this grinding disc is double the ordinary.

The use of newly designed professional bearings, and reach a high rotation rate. At the same time using only one drive motor, to ensure the efficient grinding crash, which greatly saves the time and operation of machinery and control engineering.

Installation and maintenance easy, open the door to cover clean-up.

Milling process of the whole seal, without dust leakage.

Full automatic feeding, the materials and sorting.

Grinding gap adjustment is simple, just use the plug-foot bolts and adjustments can be fine-tuning (10-120 mesh).

The host used the water and wind double system; Rational design of smaller cross-section of the grinding chamber, grinding is almost flat vertical surface. Material entered the grinding chamber as soon as caught, groud, and then rapidly removed, which eliminates the grinding chamber of the surge in materials, heating materials to avoid decomposition, resulting in improved production.

Specifications

1. high capacity

2. Working stably

3. Lower energy consumption

It is applied for PVC, PE, LDPE, LLDPE, ABS, EVA, PS, PET and rubber

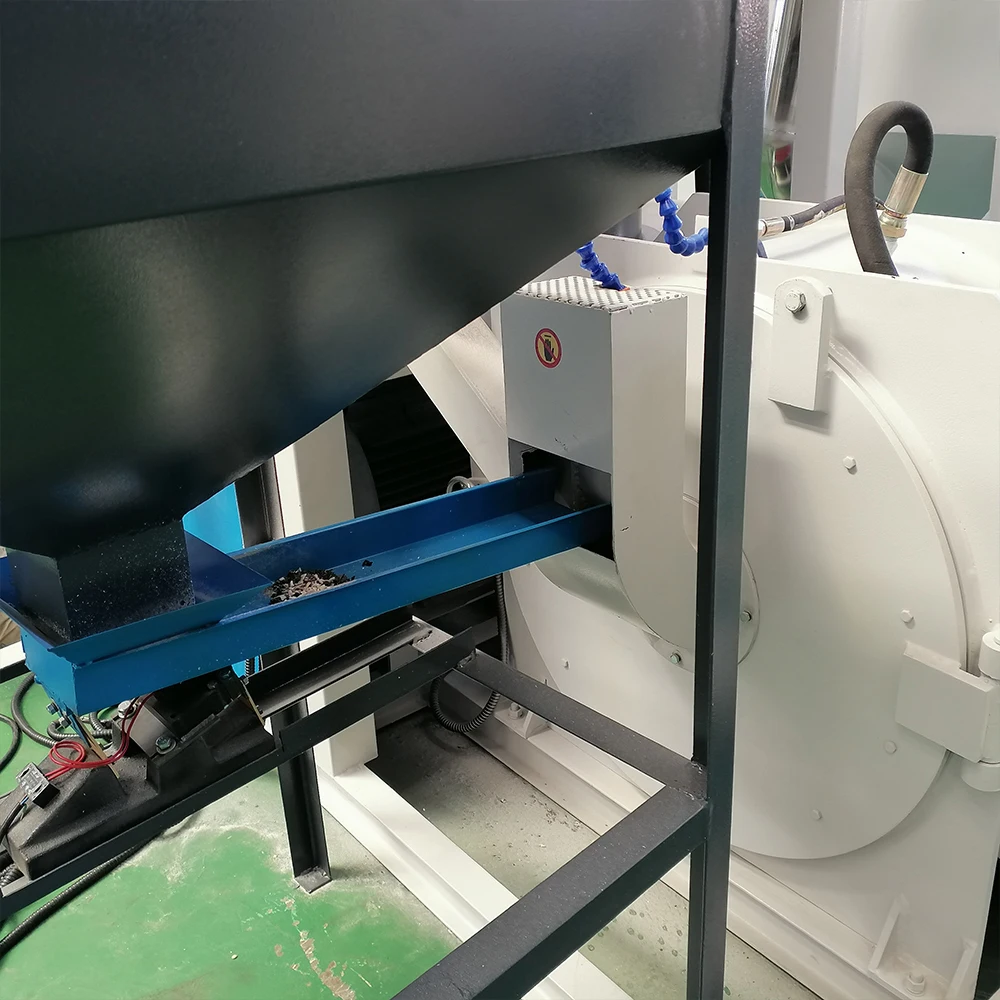

components:

1. Grinding room

2. Main motor

3. Wind-sending pipeline

4. Hopper

5. Shaking feeder

6. Rotundity vibrating sieve

7. Cyclone wind butterfly valve

8. Cyclone separater

9. Blower

10. Electrical control cabinet

11. Dust catcher.

Features of miller grinder:

1.The machine is adapt for heat-sensitive material processing by circulating water cooling

2.The machine is using two grind disc to smash material. Collision two disc and change input material into powder.Without sieve.

3.The disc is made of wear-resistant steel,which is through heat treatment.

4.High tight-compact,small size,maintenance should be happen before opening cover.all-sealed,dust-free spill.

5.The machine is equipped with wind blow device to ensure cool average.fast cooling characteristic.

6.The machine is equipped with vibra sieve which can select material according to diameter of material.

7.Equipped with dust-free device to decrease dust.

This machine is used for PVC, PE, LDPE, LLDPE, ABS, EVA, PS, PET and rubber.

The Equipment characteristics: high-quality tool is easily to replace, long life, low power consumption, high output, simple structure, easy installation, the host has the wind and water cycle cooling system, automatic feeding device,dust removal equipment, aircraft high degree of automation, effective, significantly reduced labor intensity.

Our factory developed the SMF Series rotor automatic plastic milling machine on the basis of advanced Foreign technology, mainly used in plastics, mining, chemical, and metallurgical industries for micro-milling equipment. Especially, used for recycled PVC plastic grind. Improved by the plastic manufacturer in practice, add 20% -30% of its grinding powder in the process, the chemical and physical data keep the same as 100% first hand raw material.

Model | SMF-200 | SMF-380 | SMF-450 | SMF-500 | SMF-600 | SMF-800 | |

Blade diameter | 200mm | 380mm | 450mm | 500mm | 600mm | 800mm | |

Lade disk quantity | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | |

Rotated speed | 4500rpm | 4500rpm | 4500rpm | 4500rpm | 4200rpm | 3700rpm | |

Power | main motor | 11Kw | 30Kw | 30Kw | 37Kw | 37Kw | 45Kw |

blower | 2.2Kw | 3Kw | 4Kw | 3Kw | 4Kw | 5.5Kw | |

Shaker size | 600mm | 800mm | 800mm | 800mm | 1000mm | 1200mm | |

Output size | 10-100 mesh 140μm-1400μm | ||||||

Cooling type | Air and Water | ||||||

Capacity | PVC: 100kg | PVC: 200kg | PVC: 250kg | PVC: 250kg | PVC: 350kg | PVC: 500kg | |

P E: 50kg | P E: 150kg | P E: 180kg | P E: 200kg | P E:250kg | P E: 300kg | ||

P P:30kg | P P:70kg | P P: 80kg | P P: 100kg | P P: 160kg | P P: 200kg | ||

Dimensions (mm) | 2000x1700x2000 | 2500x2000x3000 | 2600x2100x3000 | 2600x2100x3000 | 2800x2300x3000 | 3200x2800x3200 | |

Zhangjiagang sevenstars is located in Zhangjiagang city, China, a beautiful and famous city for all kinds of plastic machine.

We have 17000 square meters land and new modern workshop, we mainly development, design, manufacture and marketing plastic pelletizing machine, plastic recycling machine, pet bottle recycling machine, PVC pipe making machine, PE pipe making machine, PVC foam board production line, plastic granulator, plastic shredder, plastic pulverizer, Plastic agglomerator, single shaft shredder, double shaft shredder, plastic crusher and so on. By the several years developing, we grown up to a middle scale company in China plastic industry.

As one of the reliable supplier in China, We have keeping improved our management and technology level. Up to now, we have earned good reputation in domestic and abroad market. And our products have been exported to many countries, like mexico, America, Argentina, Chile, Brazil, Russia and so on.

Quality and honest is our foundation, customer satisfactory is our job, to get “Win-Win” is our main targe. We always focus on improving our quality. And we have buit up a professional after-sale services team with rich-experienced in machine commissioning and installation. We believe our quality and service will bring success to each customer.

Welcome final users and distributors from all the world contact with us and create success

With your support and our effort, we deeply believe that the tomorrow of sevenstar will be much better.

1. Inspection service:

◊ After informed machines ready for inspection, customer can send engineers to HORSERIDER factory for inspection and test. Customer can also consign HORSERIDER to finish inspection work.

◊ After the machines are delivered to customer’s factory, please arrange preparation work for installation

2. Installation and testing service:

◊ HORSERIDER will send technicians to the factory after preparation work is completed;

◊ Technicians will be responsible for guide on-site installation and testing machines

◊ Meanwhile technicians will give for free training lessons to labors in customer’s factory.

◊ The customer just needs to bear expenses generated for this work, e.g. visa-application, airplane tickets (round-way), trip expense(round-way), residency, meals and allowance of USD80 per day for each technician.

3. Guarantee period and after-sales service:

◊ 15 months since installation finish and running

◊ During this guarantee period, HORSERIDER will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, HORSERIDER will provide the buyer spare parts at cost price.

4. Long-term service:

HORSERIDER will charge the buyer cost price of spare parts beyond 15 months and provide long-term technical guide.

1. Are you factory or trading company?

2. Which payment term is accepted?

30% in advanced payment+70% payment paid before shipment.

Welcome your inspection before shipment.

3.How about the quality about this machine?

Yes,my friend,please rest assured,we have nearly 10 years experience for this machine.quality is no problem.

4.How about the output about this machine?is the data real?

My friend,we have tested that machine many times,then get this data,it is real and can meet your need.

5.Wether you deliver in time?

Sure,once we receive your payment, then delivery immediately.

6.What about your after service?

We can send our engineers to you factory and offer long term technical guidance.

7. How to visit your factory?

Our factory is in Changshu city, Jiangsu Province, about one hour drive from Shanghai. Welcome to visit us!