Хит продаж 2 мм-19 мм поплавковое прозрачное стекло для

- Категория: Tempered glass >>>

- Поставщик: Shenzhen,Vsom,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.53 $* | 0.43 $* |

| Aug-20-2025 | 0.9 $* | 0.83 $* |

| Jul-20-2025 | 0.84 $* | 0.55 $* |

| Jun-20-2025 | 0.1 $* | 0.31 $* |

| May-20-2025 | 0.24 $* | 0.9 $* |

| Apr-20-2025 | 0.36 $* | 0.91 $* |

| Mar-20-2025 | 0.67 $* | 0.76 $* |

| Feb-20-2025 | 0.41 $* | 0.65 $* |

| Jan-20-2025 | 0.10 $* | 0.67 $* |

Характеристики

Products Description

Roperties Of Float Glass

How lt's Made?

Step 1: Batch Mixing

lt begins with the earth's abundant raw materials: sand.Glass itself is also an ingredient. lts recycling reduces the

need for raw materials and accelerates the melting process. Next, the silica sand, soda ash, limestone,and other raw

materials mix in proportion and sending into a furnace. The raw material will be heated at about 1500°℃ in the

furnace to become liquid and merges.Then, it's ready to leave the melting furnace and enter a bath of molten tin.

Step 2: Molten Tin Float Bath

The glass comes out from the furnace, flows gently and spreads out, looks like honey, and becomes a flat continuous

ribbon in the tin bath.As we know, tin is a low melting point metal; its molten liquid level is flat and smooth. As a

result, it makes glass a good flatness and no water ripples. In addition, there're top rolls to act on the spread surface

of the glass, control the glass speed and thickness.

Step 3: Annealing Lehr

At the end of the float bath, the glass is cooled down further and leaves the tin bath at 600°℃, when it is just solid

enough to climb on metallic rollers and be driven inside the lehr. In the lehr area, the glass is annealed and gradually

cooled to relieve inner stresses and prevents splitting in the cutting phase: cool down too quickly, it would break.

lt begins with the earth's abundant raw materials: sand.Glass itself is also an ingredient. lts recycling reduces the

need for raw materials and accelerates the melting process. Next, the silica sand, soda ash, limestone,and other raw

materials mix in proportion and sending into a furnace. The raw material will be heated at about 1500°℃ in the

furnace to become liquid and merges.Then, it's ready to leave the melting furnace and enter a bath of molten tin.

Step 2: Molten Tin Float Bath

The glass comes out from the furnace, flows gently and spreads out, looks like honey, and becomes a flat continuous

ribbon in the tin bath.As we know, tin is a low melting point metal; its molten liquid level is flat and smooth. As a

result, it makes glass a good flatness and no water ripples. In addition, there're top rolls to act on the spread surface

of the glass, control the glass speed and thickness.

Step 3: Annealing Lehr

At the end of the float bath, the glass is cooled down further and leaves the tin bath at 600°℃, when it is just solid

enough to climb on metallic rollers and be driven inside the lehr. In the lehr area, the glass is annealed and gradually

cooled to relieve inner stresses and prevents splitting in the cutting phase: cool down too quickly, it would break.

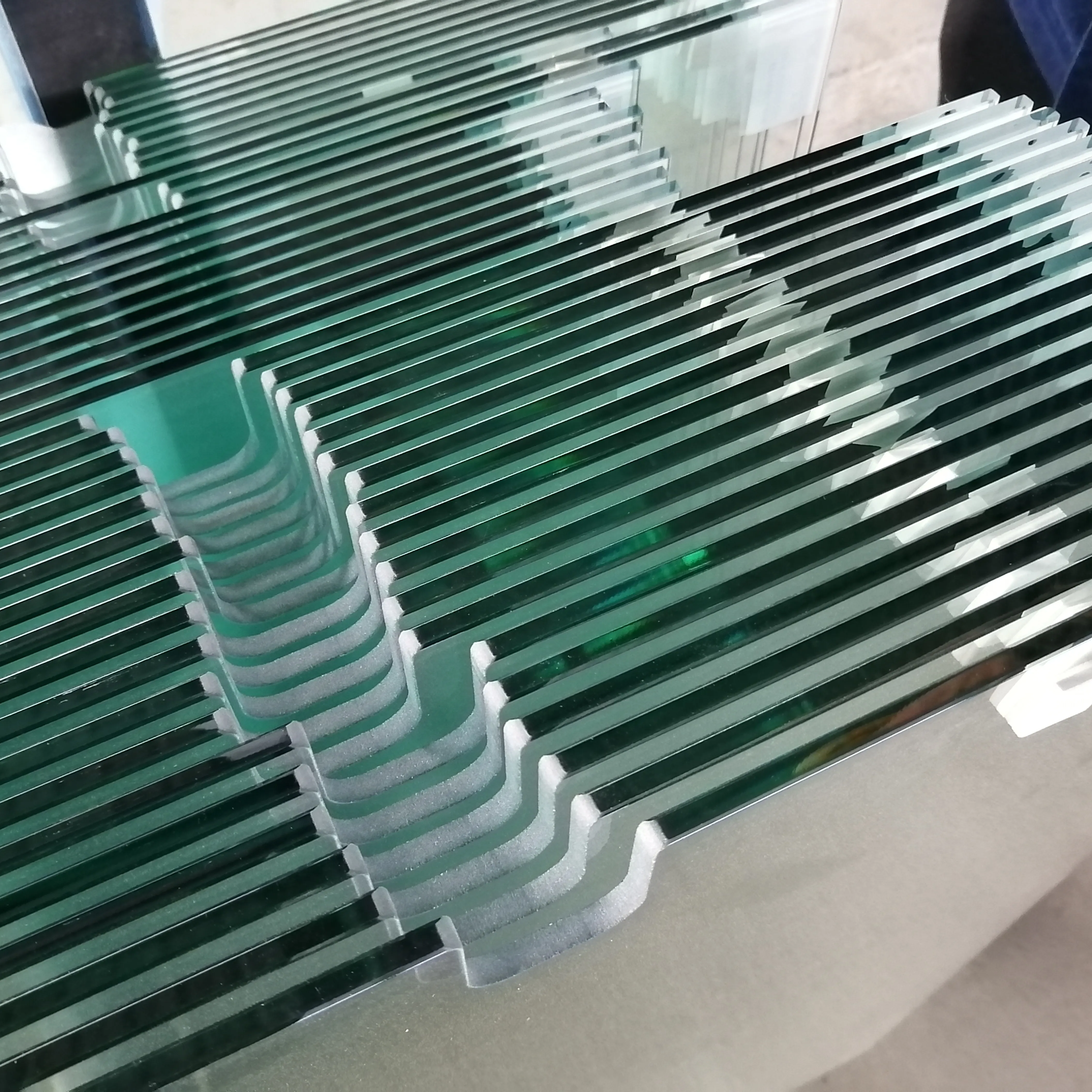

Step 4: Inspection& Cutting

After the cooling, high-performance scanners detect all kinds of defects and identify imperfections to be discarded. When the glass passes the quality inspection, it will be cut into desired dimensions and packed depends on specific

customer requirements.

After the cooling, high-performance scanners detect all kinds of defects and identify imperfections to be discarded. When the glass passes the quality inspection, it will be cut into desired dimensions and packed depends on specific

customer requirements.

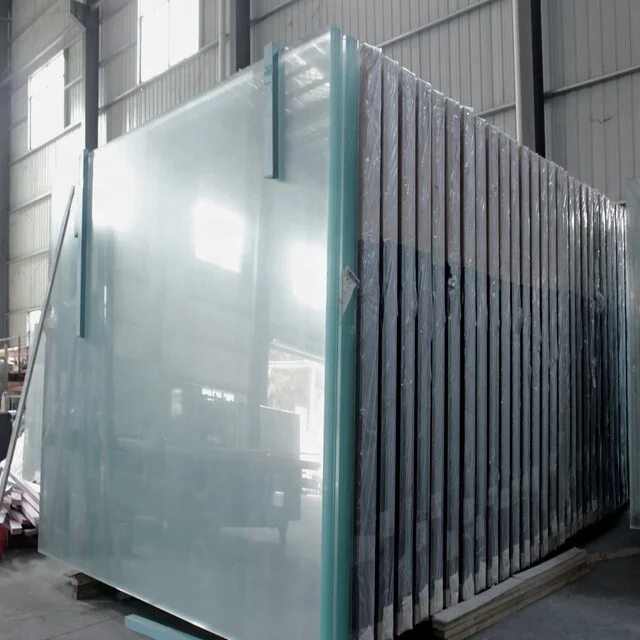

Specification

Product Name | Float Glass |

Thickness | 2mm,3mm,4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm,19mm 22mm 25mm etc |

Size | Customized sizes are available |

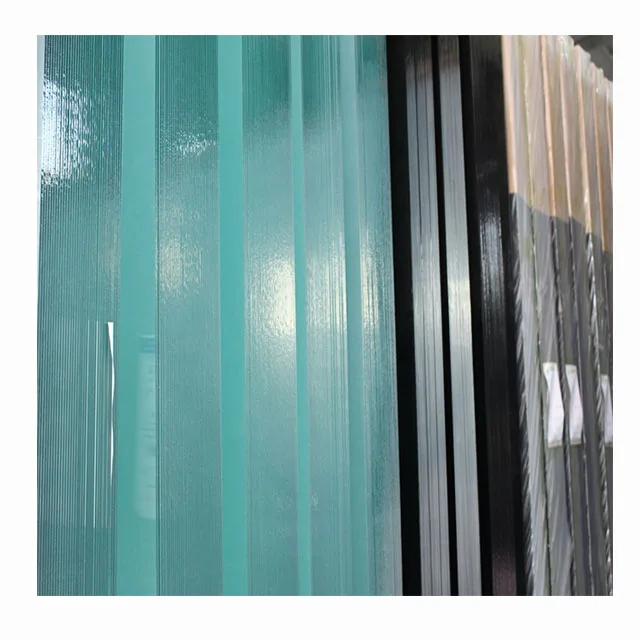

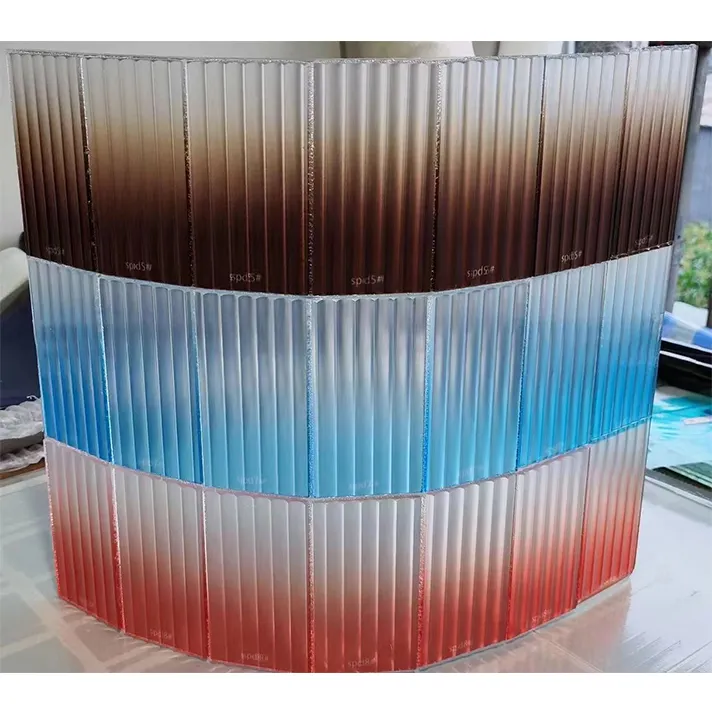

Color | super clear |

shapes | Flat float glass |

Processing Standard | CE, SGCC, SAI, GB |

Applications | Most safety and decorative glass, such as laminated glass and toughened glass, is further process by standard float glass. In the building industry, it makes curtain walls, doors, and windows, partitions, etc. While in the automobile industry, it makes windshields, windows, etc. Moreover, it makes mirrors, tables, shelves, display cabinets, and many other consumer products. lt is the most widespread form of glass in today's world. |

Company Profile

Packing & shipping

FAQ