Умный Комплект тестирования температуры Gidape водонагреватель с толстой

- Категория: Industrial Heater >>>

- Поставщик: Xinxiang,Jieda,Precision,Electronics,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 129.42 $* | 135.33 $* |

| Aug-18-2025 | 127.92 $* | 133.75 $* |

| Jul-18-2025 | 107.86 $* | 112.99 $* |

| Jun-18-2025 | 125.12 $* | 131.36 $* |

| May-18-2025 | 109.57 $* | 114.89 $* |

| Apr-18-2025 | 123.66 $* | 129.74 $* |

| Mar-18-2025 | 122.84 $* | 128.31 $* |

| Feb-18-2025 | 121.63 $* | 127.85 $* |

| Jan-18-2025 | 120.32 $* | 126.91 $* |

Характеристики

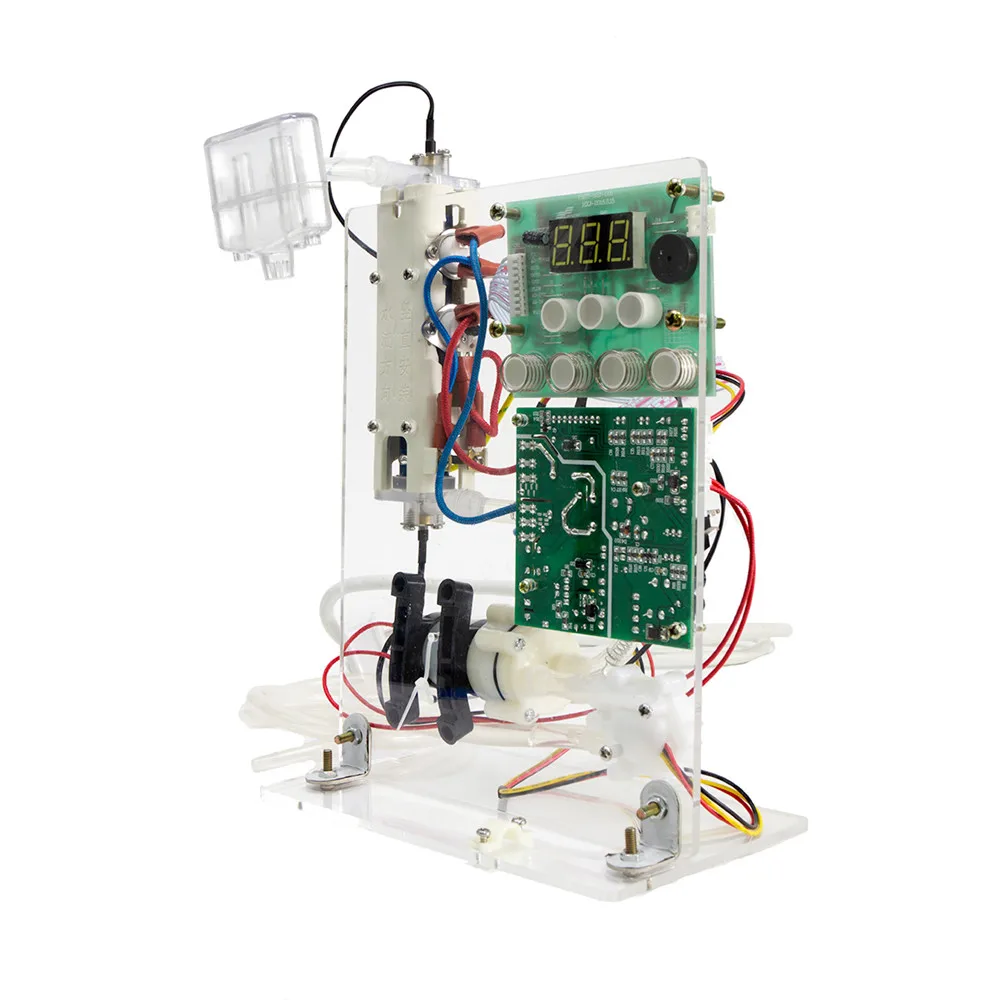

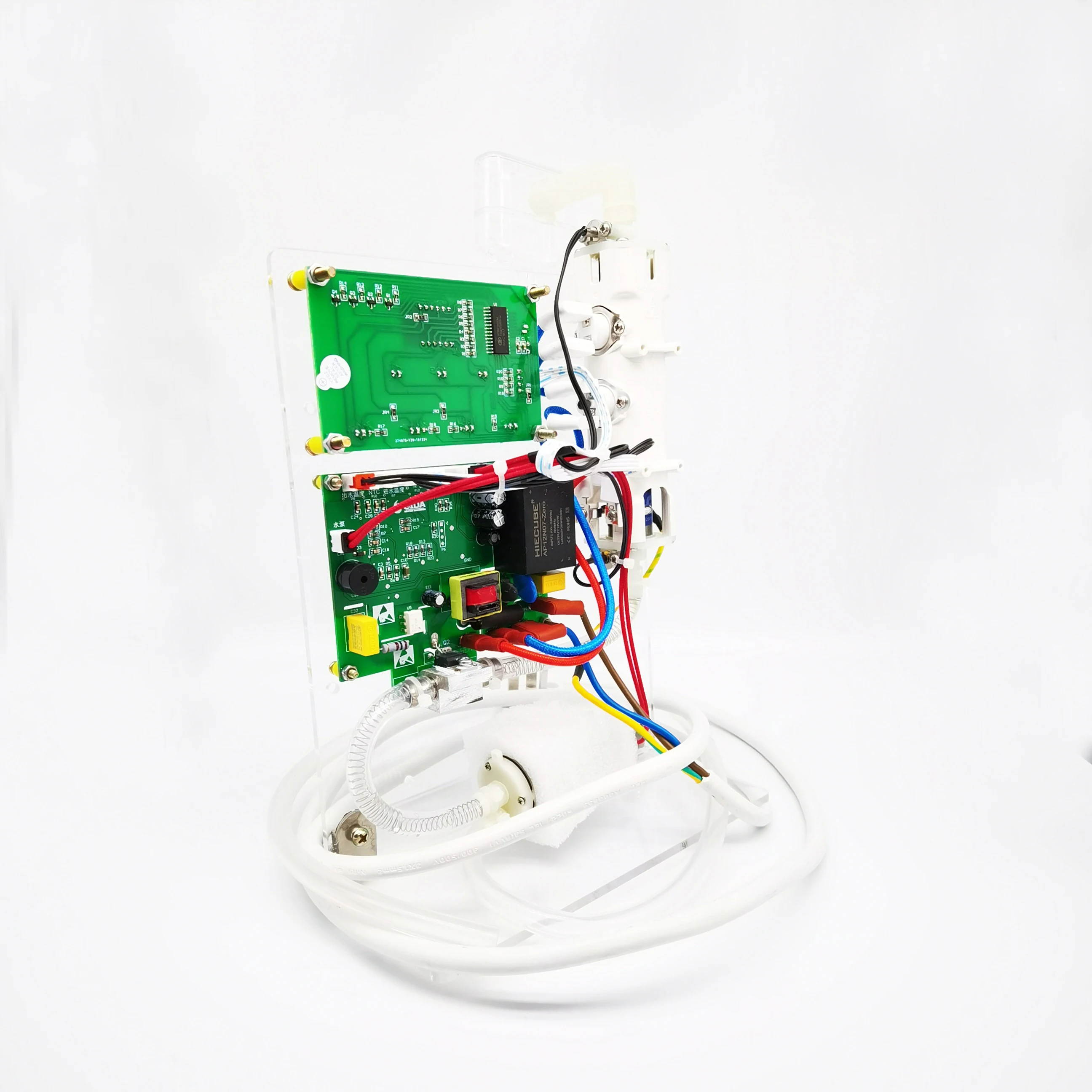

Smart temperature control Test Kit Thick Film Water Heater 20BJ Module

Product Description

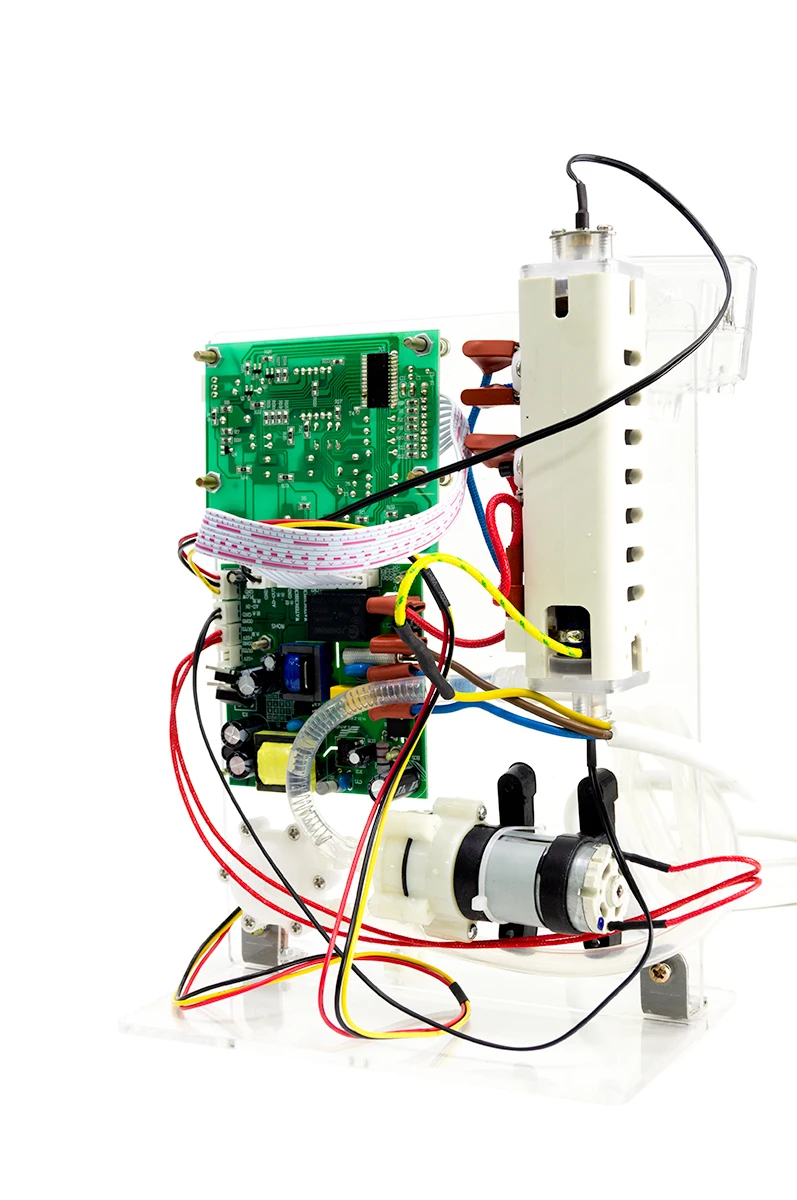

In order to make clients to test Thick Film Electric Heating Elements soonly, we launch this new model with full set of temperature & flow traffic control module.

You'll find our heating elements is better on power saving and thermal transfer (up to 96% - 98%). This is proofed by our customers.

You can set different power, temperature and flow traffic. For the order in bulk, we can customize the full application solution or just provide the Electric Heating Elements.

Feature | temperature and flow control | Heat Density | >60W/cm² |

Ramp-Up Rate | 80℃/s | Thermal Efficiency | >96% |

Heating Power | 2,200W | Service Life | >10,000 hours |

Rated Voltage | 220v | Certificate | CQC, RoHS |

Dielectric Strength | 1,500V/5mA/60s | Power Deviation | -10% - +5% |

Leakage Current | ≤0.25mA | Insulation Resistance | ≥200MΩ |

Type | PA66+ glass fibre, temperature resistance≥250℃ | Snap Action Thermostat | 16A, installed close to the heating tube’s heating circuit |

Shield Thermistor | PTC | Grounding Type | Spot-Weld |

Water Inlet & Outlet | Φ10mm | Heating Tube Dimention | Φ20mm*120mm |

Main Features

1. Electric Circuit printed on stainless steel tube surface, to heating the water flow inside. 5 isolation layers sintered on the surface.

2. Large heat transfer area on tube surface; Ramp up and Cool down quickly; High utilization rate up to 93% or above.

3. Fast temperature response, power density is as high as 40W/cm² and heating circuit’s temperature raising rate exceeds 80℃/s.

4. Simple Structure, Compact Profile, Various Applications

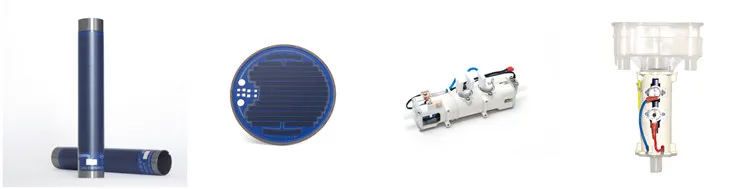

Those thick film heating tubes/elements are widely applied in Instant Water Boiling, Instant Water Heater, Water Dispensers, Coffee Makers, Instant Electric Heating Faucets, Steam Generator, Air-Flow Heater, Floor Heating, Industrial Water Flow Heating, etc.

It can successfully replace the Traditional Electric Heating Tubes/Elements, change their structures and performance completely, which can reduce energy consumption, increase energy utilization and save space.

| Instant water heat tube | Instant water heat plate | Instant water heat element | The boiled water machine heat element |

Jieda was founded in 2012, is a high-tech manufacturer that specializes in design, research, produce and sales rare-earth metal thick film electric heating tubes/elements.

What is Jieda advanced in?

1. More than 8 years experiences in thick film electric heating tubes.

2. Fully mastery of thick film tube surface screen printing and sintering.

3. Main Process Flow in 10000+ Grade Air Purification Workshop.

4. First manufacturer to mass produce Thick Film Electric Heating Tube/Element in China

5. Available various Solutions for fluid heating, especially for Instant Water Heating Home Appliances, House Floor Heating and Industrial water flow heating.

6. Monthly production capacity is up to 300,000 pcs.

Q: What's Thick Film Heating Element? A: Thick Film Heater is a new technical art which is use screen printing technology and new thick film material. It is printed with isolation dielectric, heating element and glass prevent on a substrate that is made by stainless steel, amd through drying firing process with 800°C. Thick Film Heater has become a new type of heater. |

Q: What’s the advantages of Jieda Thick Film Heating Element? 60W/CM² POWER DENSITY up to 150℃/S TEMPERATURE RANP UP |

Q: What's the lifespan of Thick Film Heating Tube / Thick Film Heating Element? |

Q: What's the inlet and outlet diameter? Thick Film Heating Element : Available with Ø10mm, Ø16mm, G1/2 G1/4 and G1/8 |

Q: Can I DIY it for personal use by myself? A: Our Products are mainly used as heating spare parts for water heaters in mass production, not recommended for Personal DIY. |

Q: Can the Thick Film be applied to Copper Pipe or Aluminum Pipe? A: It can not be applied on Copper pipe, but can work on Aluminum pipe. |

Q: How to get the suitable model for our application? and other special requirements, to recommend the suitable Thick Film Heating Elements |

Q: What's the operation attentions? 2. Please install it vertically, make sure water flow direction from bottom to top, to prevent DRY HEATING in partial area of heating tube. 3. Set the minimum flow rate according to tubes' power watts, ensure smooth flowing of water, to prevent vaporizing and dry heating 4. Make sure reliablility grounding. |