Эмульсионный битумный завод для производства асфальта с использованием битумной

- Категория: Asphalt Mixers >>>

- Поставщик: Titeco,Industry,Technology,Inc.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.82 $* | 0.17 $* |

| Aug-16-2025 | 0.74 $* | 0.86 $* |

| Jul-16-2025 | 0.54 $* | 0.35 $* |

| Jun-16-2025 | 0.77 $* | 0.62 $* |

| May-16-2025 | 0.82 $* | 0.8 $* |

| Apr-16-2025 | 0.38 $* | 0.63 $* |

| Mar-16-2025 | 0.80 $* | 0.33 $* |

| Feb-16-2025 | 0.25 $* | 0.18 $* |

| Jan-16-2025 | 0.68 $* | 0.51 $* |

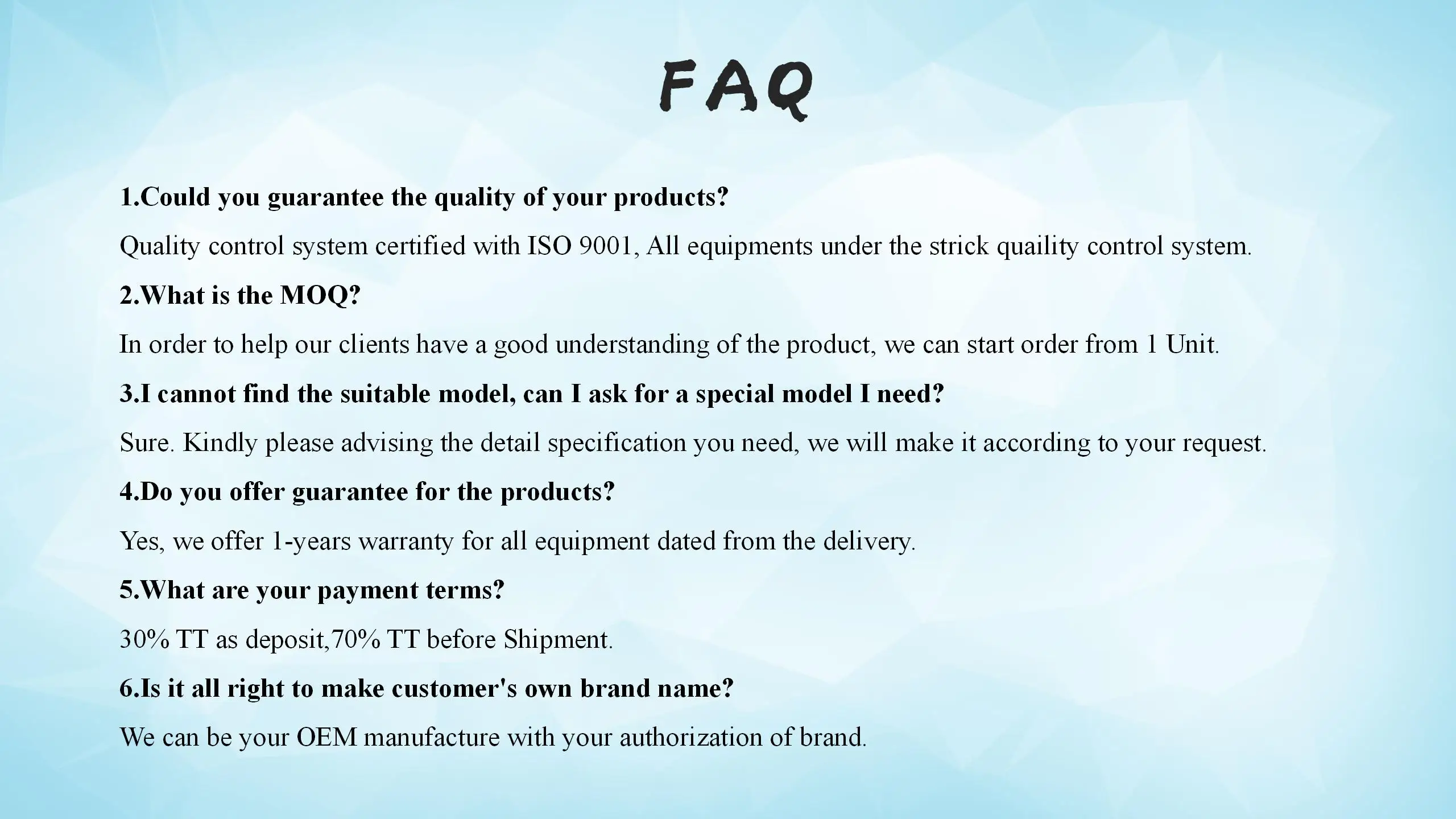

Характеристики

Products Description

Bitumen(Asphalt) Emulsion Plant

Introduction:

Emulsion bitumen plant is to produce emulsified bitumen, SBR modified emulsion bitumen . Because of its simple structure and convenient operation, MTR10C emulsion bitumen equipment is widely used in the production of various types of emulsion asphalt, and its capacity is 10 tons/hour.

The equipment consists of a 6M3 asphalt storage tank, two 3M3 soap preparation tanks, one 2.25 M3 finished product buffer tank, frequency conversion control asphalt pump, emulsion pump, regulating valve, flow meter, emulsifying machine, finished product output pump, electrical control box, filter, valve and its pipeline parts.

Features:

*The unique mixing tank structure can realize the advance preparation of emulsifier (and latex) and effectively save production time.

*The asphalt pump is controlled by frequency converter. Compared with the motor speed regulation in the past, it has the advantages of simple operation and high metering accuracy.

*Soap delivery adopts real-time metering by flowmeter and valve regulation control. It is simple and intuitive to operate.

*Use the famous brand emulsifying machine, can produce normal emulsion bitumen , SBR modified emulsion bitumen.

*Emulsifying machine rotor and stator are made of imported high-quality stainless steel corrosion-resistant material, which prolongs the life of the mill.

*The clearance between rotor and stator of colloidal mill can be adjusted accurately . By adjusting the clearance, various types of high quality emulsion bitumen can be produced, so that the emulsion bitumen has excellent particle size distribution effect.

*Equipped with hot oil contact valve, it is safe, fast, high heating efficiency, short preheating standby time, reduce production auxiliary time and improve production efficiency.

Introduction:

Emulsion bitumen plant is to produce emulsified bitumen, SBR modified emulsion bitumen . Because of its simple structure and convenient operation, MTR10C emulsion bitumen equipment is widely used in the production of various types of emulsion asphalt, and its capacity is 10 tons/hour.

The equipment consists of a 6M3 asphalt storage tank, two 3M3 soap preparation tanks, one 2.25 M3 finished product buffer tank, frequency conversion control asphalt pump, emulsion pump, regulating valve, flow meter, emulsifying machine, finished product output pump, electrical control box, filter, valve and its pipeline parts.

Features:

*The unique mixing tank structure can realize the advance preparation of emulsifier (and latex) and effectively save production time.

*The asphalt pump is controlled by frequency converter. Compared with the motor speed regulation in the past, it has the advantages of simple operation and high metering accuracy.

*Soap delivery adopts real-time metering by flowmeter and valve regulation control. It is simple and intuitive to operate.

*Use the famous brand emulsifying machine, can produce normal emulsion bitumen , SBR modified emulsion bitumen.

*Emulsifying machine rotor and stator are made of imported high-quality stainless steel corrosion-resistant material, which prolongs the life of the mill.

*The clearance between rotor and stator of colloidal mill can be adjusted accurately . By adjusting the clearance, various types of high quality emulsion bitumen can be produced, so that the emulsion bitumen has excellent particle size distribution effect.

*Equipped with hot oil contact valve, it is safe, fast, high heating efficiency, short preheating standby time, reduce production auxiliary time and improve production efficiency.

Emulsion bitumen plant | ||||

Model | MTR6 | MTR10 | ||

Max. Capacity | 6T/h | 10T/h | ||

Voltage | 380V , 50HZ | |||

Oil water rate | 5:5~6:4 | |||

Main engine Dimension (LxWxH) | 8000×2250×2500 mm | 9000×2200×2500 mm | ||

Company Profile

TITECO is a global producer of construction equipment and vehicles, which is specialist in road building, repair and maintenance machinery equipment and vehicles. We offer our customers technologically first-class quality products, creative design services and sound service for optimum, economic production processes. With over 20 years experience in concrete & asphalt road building and maintenance, TITECO's applied technology service will help you to improve your performance. All our products are synonymous of power and stability, always provide the innovative solutions for complex issues.

Our Advantages

1. More than 20 years of cutting edge innovation and expertise help us to provide you all the best solutions of your projects.

2. With all kinds of our products commissioned for the concrete and asphalt industry projects,we believed that we know the cares and concerns of our customers well.

3. TITECO manufactures all equipment in our own factory under the strick quaility control system, makes the equipment much more reliable.

Production Process

Partner

Product Packaging