Suncenter Automatic Hydro testing Valve Pressure Test Machine Diameter

- Категория: Testing Equipment >>>

- Поставщик: Dongguan,Suncenter,Fluid,Control,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 9520.81 $* | 9996.52 $* |

| Aug-18-2025 | 9440.37 $* | 9912.14 $* |

| Jul-18-2025 | 7920.30 $* | 8316.7 $* |

| Jun-18-2025 | 9280.91 $* | 9744.30 $* |

| May-18-2025 | 8080.63 $* | 8484.68 $* |

| Apr-18-2025 | 9120.27 $* | 9576.25 $* |

| Mar-18-2025 | 9040.90 $* | 9492.74 $* |

| Feb-18-2025 | 8960.43 $* | 9408.67 $* |

| Jan-18-2025 | 8880.45 $* | 9324.63 $* |

Характеристики

Valve test bench for flanged or welded globe valves, ball valves and

regulating valves

regulating valves

Introduction:

The SST-H600 hydraulic valve test bench is based on our company's many years technology of producing valve testing equipment, strictly in accordance with the ISO9001 quality management system for management and production. According to GB/T13927-2008 "General Valve Pressure Test", GB/T26480-2011 "Valve Test and Inspection" and AP1598 American Standard and other relevant standards.

The hydraulic valve test bench is a combination of hydraulic, mechanical, electrical and medium storage cycle. It has the advantages of reasonable structure, perfect function, stable performance and high degree of automation. At the same time, it is widely used in the test of high, medium and low pressure sealing and strength of straight through flange or welded valve with nominal diameter of DN50-300mm. It is also used in valve manufacturing, petroleum and petrochemical industry Natural gas, water supply and drainage engineering, power plants, valve repair stations and other industries the most ideal valve test equipment.

SST-H300 model instruction and working principle

1 SST-H300 Hydraulic valve test bench consists of hydraulic system, electrical control system, high & low pressure water pump pressure supply device system, oil pressure, water pressure instrument system, control valve system, clamping table system and hydraulic medium storage circulating water tank. The test process and results meet the relevant regulations and requirements.

2 The test bench adopts end face O-ring seal, and the jacking oil cylinder is directly tightened by the end face of the valve tested. The jacking oil cylinder is directly driven by hydraulic pressure. It can be pushed in and out in the axial direction without the limitation of structure length. There is a large distance between the pull rods and is not limited by the diameter of valve flange.

3 The high-pressure water pump is powered by 4-7bar air pressure system, and automatically reverses by electric control reversing valve, which makes the high-pressure pump automaticall

The SST-H600 hydraulic valve test bench is based on our company's many years technology of producing valve testing equipment, strictly in accordance with the ISO9001 quality management system for management and production. According to GB/T13927-2008 "General Valve Pressure Test", GB/T26480-2011 "Valve Test and Inspection" and AP1598 American Standard and other relevant standards.

The hydraulic valve test bench is a combination of hydraulic, mechanical, electrical and medium storage cycle. It has the advantages of reasonable structure, perfect function, stable performance and high degree of automation. At the same time, it is widely used in the test of high, medium and low pressure sealing and strength of straight through flange or welded valve with nominal diameter of DN50-300mm. It is also used in valve manufacturing, petroleum and petrochemical industry Natural gas, water supply and drainage engineering, power plants, valve repair stations and other industries the most ideal valve test equipment.

SST-H300 model instruction and working principle

1 SST-H300 Hydraulic valve test bench consists of hydraulic system, electrical control system, high & low pressure water pump pressure supply device system, oil pressure, water pressure instrument system, control valve system, clamping table system and hydraulic medium storage circulating water tank. The test process and results meet the relevant regulations and requirements.

2 The test bench adopts end face O-ring seal, and the jacking oil cylinder is directly tightened by the end face of the valve tested. The jacking oil cylinder is directly driven by hydraulic pressure. It can be pushed in and out in the axial direction without the limitation of structure length. There is a large distance between the pull rods and is not limited by the diameter of valve flange.

3 The high-pressure water pump is powered by 4-7bar air pressure system, and automatically reverses by electric control reversing valve, which makes the high-pressure pump automaticall

4 Working process: According to the valve’s nominal diameter and adjust the compression pressure of the oil cylinder(refer to the pressure comparison table)--compress the work-piece--turn on the low pressure water pump for quick water injection--turn on the high pressure water pump--turn on the pressure holding timer--pressure relief, reset.

5 Set the compression oil cylinder and the medium pressure interlock function: when there is pressure in the test valve cavity, the compression oil cylinder cannot be loosened. Prevent operation failure play a protective role in the wrong time.

6 The buyer need to prepare 46# anti-wear hydraulic oil, 8bar air source and cable

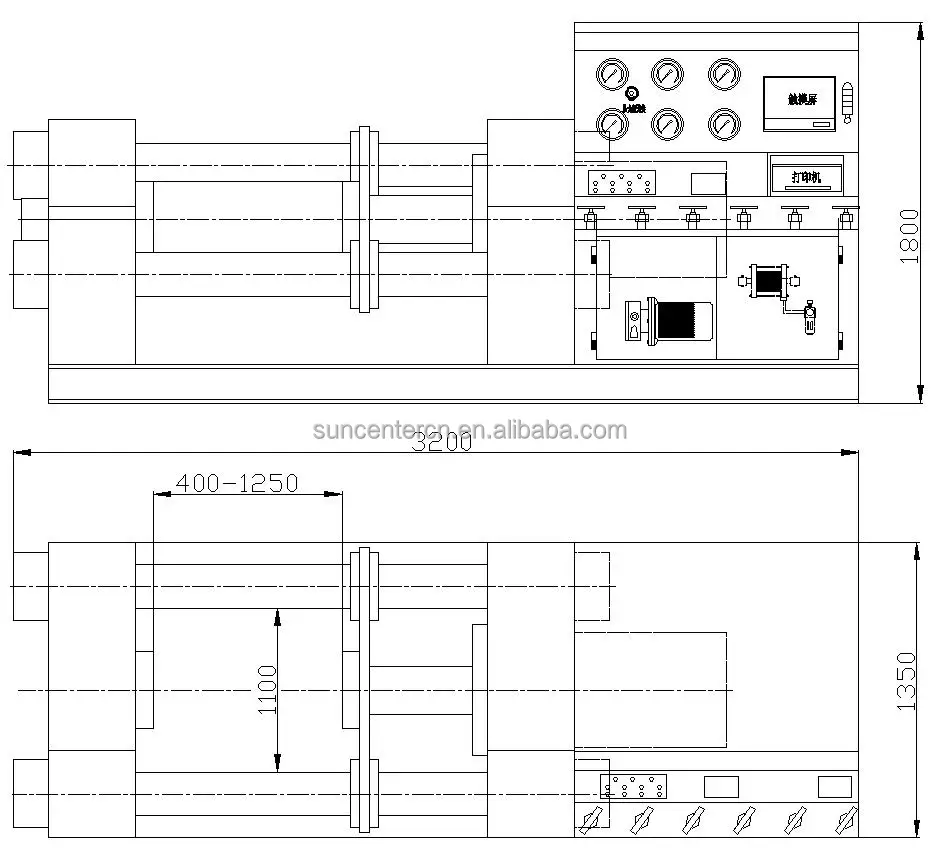

7 Equipment dimensions: 3300mm long × 950mm wide × 1800mm high, weight approximately: 3000Kg

Mainly parameter:

1. Test valve types: straight-through flanged or welded globe valves, ball valves and regulating valves.

2. Clamping method: the hydraulic cylinder is

top-pressured and the end face is sealed, which has minimal influence on the external force of the valve.

3. Sealing method of valve and blind plate:

O-ring seal on the end face.

4. Pressure test medium: water or air.

5. Complete the test items: 4-7bar low

pressure air tightness test, 1.5 times the nominal pressure water pressure shell pressure test and 1.1 times the nominal

pressure high pressure water seal test, 3.5 bar leakage test before the valve.

6. Start the left top pressure cylinder to complete the DN25-150 valve pressure test

6.1 Test range: DN25-150, see the pressure test range table.

6.2 Test valve structure length: 130-432mm.

6.3 Space between sealing discs: 120-480mm;

6.4 Interval between tie rods: 750mm;

6.5 Top pressure cylinder: Ø120mm;

6.6 Maximum clamping force: 30 tons;

7. Start the right top pressure cylinder to complete the DN80-300 valve pressure test;

7.1 Test range: DN80-300, see the pressure test range table;

7.2. Test valve structure length: 403-838mm;

7.3 Distance between sealing discs: 350-1000mm;

7.4 The distance between the tie rods: 750mm, which satisfies the maximum radial dimension of the tested valve: 560mm;

7.5 Top pressure cylinder: ∅280mm;

7.6 Maximum clamping force: 150 tons;

5 Set the compression oil cylinder and the medium pressure interlock function: when there is pressure in the test valve cavity, the compression oil cylinder cannot be loosened. Prevent operation failure play a protective role in the wrong time.

6 The buyer need to prepare 46# anti-wear hydraulic oil, 8bar air source and cable

7 Equipment dimensions: 3300mm long × 950mm wide × 1800mm high, weight approximately: 3000Kg

Mainly parameter:

1. Test valve types: straight-through flanged or welded globe valves, ball valves and regulating valves.

2. Clamping method: the hydraulic cylinder is

top-pressured and the end face is sealed, which has minimal influence on the external force of the valve.

3. Sealing method of valve and blind plate:

O-ring seal on the end face.

4. Pressure test medium: water or air.

5. Complete the test items: 4-7bar low

pressure air tightness test, 1.5 times the nominal pressure water pressure shell pressure test and 1.1 times the nominal

pressure high pressure water seal test, 3.5 bar leakage test before the valve.

6. Start the left top pressure cylinder to complete the DN25-150 valve pressure test

6.1 Test range: DN25-150, see the pressure test range table.

6.2 Test valve structure length: 130-432mm.

6.3 Space between sealing discs: 120-480mm;

6.4 Interval between tie rods: 750mm;

6.5 Top pressure cylinder: Ø120mm;

6.6 Maximum clamping force: 30 tons;

7. Start the right top pressure cylinder to complete the DN80-300 valve pressure test;

7.1 Test range: DN80-300, see the pressure test range table;

7.2. Test valve structure length: 403-838mm;

7.3 Distance between sealing discs: 350-1000mm;

7.4 The distance between the tie rods: 750mm, which satisfies the maximum radial dimension of the tested valve: 560mm;

7.5 Top pressure cylinder: ∅280mm;

7.6 Maximum clamping force: 150 tons;

Equipment structure outline:

Pressure testing range: Meet the requirements of straight-through welded ball valves, gate valves and stop valves.

nominal | Nominal pressure | Pressure testing range |

DN25-40 | 2.5-25.0Mpa | 2.5-37.5Mpa |

DN50 | 2.5-25.0Mpa | 2.5-37.5Mpa |

DN65 | 2.5-25.0Mpa | 2.5-37.5Mpa |

DN80 | 2.5-16.0Mpa | 2.5-24.0Mpa |

DN100 | 2.5-10.0Mpa | 2.5-15.0Mpa |

DN125 | 2.5-10.0Mpa | 2.5-15.0Mpa |

DN150 | 2.5-6.4Mpa | 2.5-9.6Mpa |

DN80 | 6.4-25.0MPa | 2.5-37.5Mpa |

DN100 | 4.0-25.0MPa | 2.5-37.5Mpa |

DN125 | 2.5-25.0MPa | 2.5-37.5Mpa |

DN150 | 2.5-25.0MPa | 2.5-37.5Mpa |

DN200 | 2.5-20.0MPa | 2.5-30.0 Mpa |

DN250 | 2.5-10.0MPa | 2.5-15.0 Mpa |

DN300 | 2.5-10.0MPa | 2.5-15.0 Mpa |

Function configuration of water and gas pipeline:

1. This test bench is equipped with a high and low pressure medium water pump. The low pressure pump is a vortex self-priming pump with high flow pressure. The full load pressure of the low pressure pump is 0-1.6Mpa. The power source of the high pressure pump is 4-7bar air pressure system reciprocating drive The pressure value of the piston and high-pressure pump is 1.6-10.0Mpa. When the tested valve reaches the required test pressure value, it has an automatic stop function. The bottom of the machine circulates the storage medium water tank, and puts the anti-rust agent (powder) in the water tank to avoid rust and corrosion of the tested valve and the pipeline one-way valve. This test bench is the most ideal equipment for water saving and environmental protection.

2. The water and gas pipeline is designed with two-way pressure inlet and pressure relief, and the designed pressure holding time is up to the sound and light alarm.

1. This test bench is equipped with a high and low pressure medium water pump. The low pressure pump is a vortex self-priming pump with high flow pressure. The full load pressure of the low pressure pump is 0-1.6Mpa. The power source of the high pressure pump is 4-7bar air pressure system reciprocating drive The pressure value of the piston and high-pressure pump is 1.6-10.0Mpa. When the tested valve reaches the required test pressure value, it has an automatic stop function. The bottom of the machine circulates the storage medium water tank, and puts the anti-rust agent (powder) in the water tank to avoid rust and corrosion of the tested valve and the pipeline one-way valve. This test bench is the most ideal equipment for water saving and environmental protection.

2. The water and gas pipeline is designed with two-way pressure inlet and pressure relief, and the designed pressure holding time is up to the sound and light alarm.

Packing&Shipping

Package: pack in plywood case

Shipment: by air/sea/express

Shipment: by air/sea/express

Company Introduction

Dongguan Suncenter Fluid Control Equipment Co., Ltd is the member company of Suncenter Group, which is located in Dongguan city of

Guangdong province in China. With more than 15 years experiences in fluid pressure exchange and controlling field, we provide

various kinds of pneumatic and hydraulic booster pumps, systems and solutions to the customers all over the world. Due to our best

product quality, competitive price as well as excellent after-sales service, we have win a great reputation in the field.

Guangdong province in China. With more than 15 years experiences in fluid pressure exchange and controlling field, we provide

various kinds of pneumatic and hydraulic booster pumps, systems and solutions to the customers all over the world. Due to our best

product quality, competitive price as well as excellent after-sales service, we have win a great reputation in the field.

Our main products including:

1. High Pressure Booster Pumps ( Gas Booster Pump, Air Driven Liquid Pump, Air Amplifiers)

2. High Pressure Systems (Gas/Liquid Booster System,Hydro test bench,Chemical injection system,CO2/FM200 filling machine, Tube Expanding Machine)

3. High Pressure Test Equipment(Hydraulic/Burst/Hydrostatic test machine,Cylinder test machine, Valve test bench,Impulse Testing Machine, etc.)

4. Hydro-pneumatic cylinders and machines(pneumatic hydraulic cylinders,pneumatic riveting machines,pneumatic press machines etc.)

Customer review

Certification

Our Advantages

-1. 15 years of manufacturing experience history.

-2. faster lead time, the fastest delivery is about 5-10 working days.

-3. CE & SGS certificate approval factory.

-4. Quality control for every step while production.

-5. Professional engineers have working experience in Maximator.

-2. faster lead time, the fastest delivery is about 5-10 working days.

-3. CE & SGS certificate approval factory.

-4. Quality control for every step while production.

-5. Professional engineers have working experience in Maximator.

FAQ

Q: Are you factory?

A: Yes, we have more than 15 years experiences in high pressure fluid exchange and controlling field,we provide various kinds of pneumatic and hydraulic boosters,systems and solutions.

Q: Where's your location? can I visit you?

A: Welcome to visit Suncenter, we are in Dongguan City, Guangdong province, China.

Q: How to operate the machine?

A: After you get the machine, we will send you the working video to teach you for maintenance and

operating.

Q: How long is your warranty?

A: 13 months.

A: Yes, we have more than 15 years experiences in high pressure fluid exchange and controlling field,we provide various kinds of pneumatic and hydraulic boosters,systems and solutions.

Q: Where's your location? can I visit you?

A: Welcome to visit Suncenter, we are in Dongguan City, Guangdong province, China.

Q: How to operate the machine?

A: After you get the machine, we will send you the working video to teach you for maintenance and

operating.

Q: How long is your warranty?

A: 13 months.