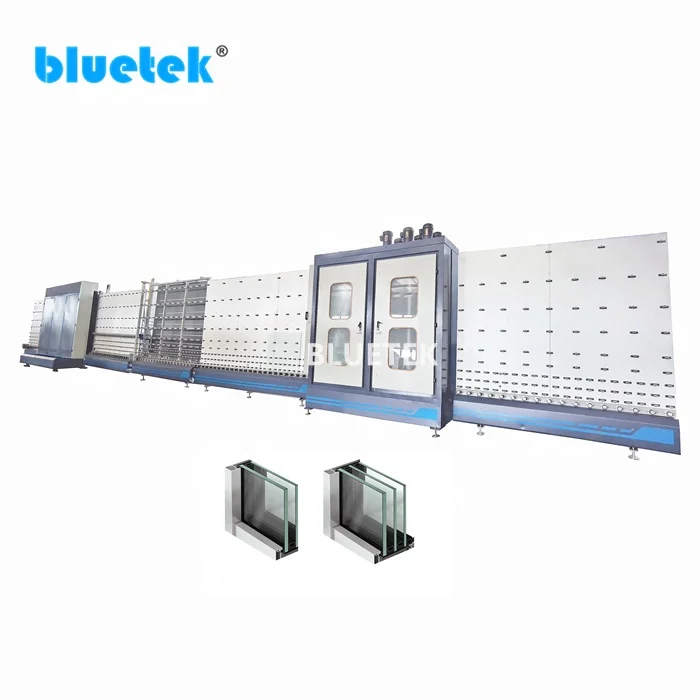

Вертикальная автоматическая машина для производства стекла с двойным остеклением 2500 мм x 3000

- Категория: Glass Processing Machinery >>>

- Поставщик: Jinan,Bluetek,Intelligent,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.61 $* | 0.6 $* |

| Aug-18-2025 | 0.23 $* | 0.58 $* |

| Jul-18-2025 | 0.94 $* | 0.73 $* |

| Jun-18-2025 | 0.30 $* | 0.18 $* |

| May-18-2025 | 0.97 $* | 0.66 $* |

| Apr-18-2025 | 0.19 $* | 0.73 $* |

| Mar-18-2025 | 0.80 $* | 0.96 $* |

| Feb-18-2025 | 0.16 $* | 0.54 $* |

| Jan-18-2025 | 0.70 $* | 0.34 $* |

Характеристики

PRODUCT DESCRIPTION

LZK2500A

Vertical Automatic Double Glazing Glass Making Machine Price

Double Glass Size : 2500mm x 3000mm

1. Vertical Automatic Double Glazing Making Machine is equipped with argon gas charging function, which is a special equipment for producing double glass with aluminum spacers. The double glazing glass production line has the advantages of small footprint, high degree of automation, high efficiency, and reliable performance. It can realize the functions of glass cleaning and drying, aluminum partition positioning assembly, automatic glass installation, argon filling, and flat pressing.

2. The whole body and water tank of the glass washing part are welded with stainless steel plates, and all parts in contact with water are made of stainless steel or corrosion-resistant materials. The top plate is 6mm stainless steel plate, the bottom plate is 8mm stainless steel plate, laser cut, CNC bending.

3. Three pairs of brushes, with adjustable bearings at the bottom of the brushes, to ensure that the brushes are concentric up and down. Can clean LOW-E glass and coated glass. Use a high-pressure nozzle for cleaning to ensure that the glass is cleaned.

4. The conveying roller of the good price double glass making machine is an acid and alkali resistant all-inclusive rubber roller, the shaft head is stainless steel, and the spacing is automatically adjusted according to the thickness of the glass. The transmission adopts stepless frequency conversion speed regulation, and the transmission speed can be adjusted at any time on the control box panel according to the ambient temperature and other conditions.

5. The glass washing system includes three independent water circulation systems: primary cleaning water system, secondary cleaning water system and spray water system. The glass is first cleaned by a two-stage cleaning water system, and then through the high-pressure spray of the water spray system. The cleaning water circuit has a water heater, which can be heated according to room temperature. In order to ensure the cleaning effect, the conductivity of the water is not more than 40μs/cm. If the water quality is poor, a water treatment device is needed. The treated water enters the spray water tank, and overflows into the cleaning water tank for recycling. The water treatment device is provided by the user.

6. The air drying system consists of a high-pressure fan, an air heating system, a circulating air return system and a pair of adjustable tilt aluminum alloy air knives. Equipped with a high-pressure centrifugal fan to ensure high-speed drying on both sides of the glass.

7. The pressing plate part automatically combines the glass plate, inflates and presses. Servo pressure is used to automatically calculate the pressure torque according to the size of the glass to ensure that the glass is evenly pressed and does not break. The inflating function in the board adopts the down-charging method, which is fast inflating and high in concentration. The local swelling concentration reaches 100%. The maximum size of gas-filled glass is 2500×3000mm.

2. The whole body and water tank of the glass washing part are welded with stainless steel plates, and all parts in contact with water are made of stainless steel or corrosion-resistant materials. The top plate is 6mm stainless steel plate, the bottom plate is 8mm stainless steel plate, laser cut, CNC bending.

3. Three pairs of brushes, with adjustable bearings at the bottom of the brushes, to ensure that the brushes are concentric up and down. Can clean LOW-E glass and coated glass. Use a high-pressure nozzle for cleaning to ensure that the glass is cleaned.

4. The conveying roller of the good price double glass making machine is an acid and alkali resistant all-inclusive rubber roller, the shaft head is stainless steel, and the spacing is automatically adjusted according to the thickness of the glass. The transmission adopts stepless frequency conversion speed regulation, and the transmission speed can be adjusted at any time on the control box panel according to the ambient temperature and other conditions.

5. The glass washing system includes three independent water circulation systems: primary cleaning water system, secondary cleaning water system and spray water system. The glass is first cleaned by a two-stage cleaning water system, and then through the high-pressure spray of the water spray system. The cleaning water circuit has a water heater, which can be heated according to room temperature. In order to ensure the cleaning effect, the conductivity of the water is not more than 40μs/cm. If the water quality is poor, a water treatment device is needed. The treated water enters the spray water tank, and overflows into the cleaning water tank for recycling. The water treatment device is provided by the user.

6. The air drying system consists of a high-pressure fan, an air heating system, a circulating air return system and a pair of adjustable tilt aluminum alloy air knives. Equipped with a high-pressure centrifugal fan to ensure high-speed drying on both sides of the glass.

7. The pressing plate part automatically combines the glass plate, inflates and presses. Servo pressure is used to automatically calculate the pressure torque according to the size of the glass to ensure that the glass is evenly pressed and does not break. The inflating function in the board adopts the down-charging method, which is fast inflating and high in concentration. The local swelling concentration reaches 100%. The maximum size of gas-filled glass is 2500×3000mm.

PRODUCT SPECIFICATIONS

No | Item | Data |

1 | Name | Vertical Double Glazing Making Machine Vertical Double Glass Making Machine |

2 | Model | LZK2500A |

3 | Power Supply | 380V 50Hz ( As Customer's Request ) |

4 | Total Power | 26KW |

5 | Max. Glass Size | 2500 x 3000 mm |

6 | Min. Glass Size | 300 x 450 mm |

7 | Glass Sheet Thickness | 3 - 18 mm |

8 | Insulating Glass Thickness | 12 - 40 mm |

9 | Glass Washing Speed | 2 - 12 M/min |

10 | Working Speed | 2 - 45 M/min |

11 | Unequal Glass Size | x : 0-150mm Y: 0-50mm |

12 | Air Working Pressure | 1 Mpa |

13 | Overall Dimension | 22000x2000x3600mm |

DETAILS IMAGES

Hollow glass positioning device

Insulating glass transfer wheel

Double Glass Pressing Part

SIEMENS control system

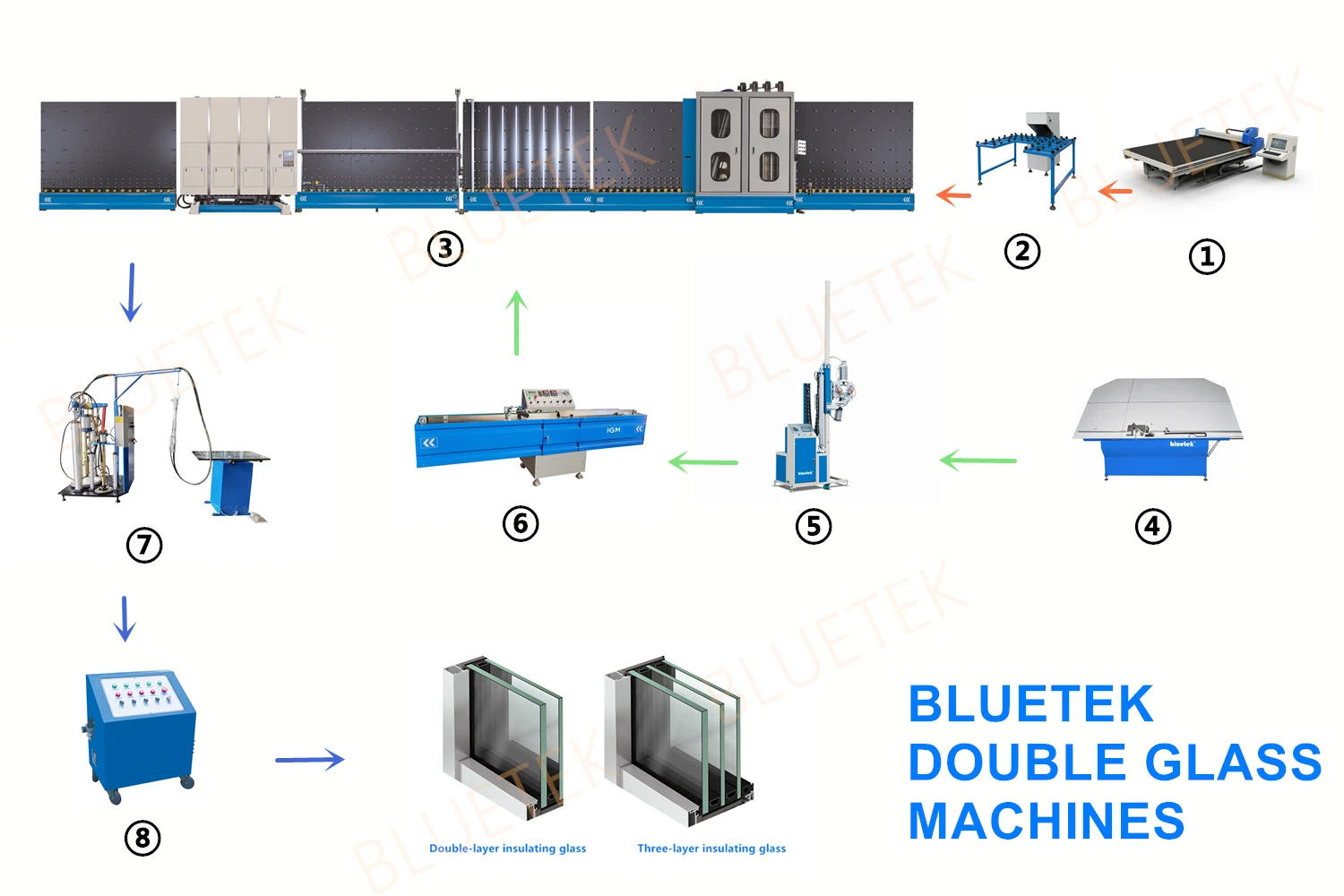

PRODUCTION SOLUTION

COMPANY PROFILE

ABOUT US

BLUETEK is a Chinese manufacturer that continues to grow and innovate. It has been committed to the development, production and service of glass deep processing machines.

As of 2020, BLUETEK has an annual output value of 700 million U.S. dollars, with an export quota of about 20%, and more than 180 customers (excluding China) in 40 countries around the world. We have two production workshops with total area of 20,000 square meters and 120 employees, including 8 core R&D personnel - with an average of 30 years of experience in the glass equipment industry.

Our products include Automatic Double Glazing Glass Making Machine, insulated glass production machine, glass washing machine, CNC glass cutting machine, and other auxiliary glass deep processing machines, including software support.

BLUETEK is one of the earliest manufacturers in China that has successfully developed and promoted automatic insulating glass sealing line. We have absorbed advanced European design concepts, combined with the needs of the Chinese window door and curtain wall market, and developed insulated glass CNC sealing line suitable for China. Contributed to the automation and intelligence of China's glass deep processing.

As of 2020, BLUETEK has an annual output value of 700 million U.S. dollars, with an export quota of about 20%, and more than 180 customers (excluding China) in 40 countries around the world. We have two production workshops with total area of 20,000 square meters and 120 employees, including 8 core R&D personnel - with an average of 30 years of experience in the glass equipment industry.

Our products include Automatic Double Glazing Glass Making Machine, insulated glass production machine, glass washing machine, CNC glass cutting machine, and other auxiliary glass deep processing machines, including software support.

BLUETEK is one of the earliest manufacturers in China that has successfully developed and promoted automatic insulating glass sealing line. We have absorbed advanced European design concepts, combined with the needs of the Chinese window door and curtain wall market, and developed insulated glass CNC sealing line suitable for China. Contributed to the automation and intelligence of China's glass deep processing.

OUR CUSTOMERS

Our automatic Insulating Glass Production Line are exported to more than 50 countries and regions around the world, and are highly praised by customers. Every year, many customers come to visit the factory. We carefully arrange every job and arrange a reasonable itinerary for our customers.

At the same time, our sales staff and after-sales service staff also visit customers overseas every year, provide customers with free maintenance services, and actively listen to customers' suggestions during use.

At the same time, our sales staff and after-sales service staff also visit customers overseas every year, provide customers with free maintenance services, and actively listen to customers' suggestions during use.

EXHIBITION

Every year we participate in professional door, window and facade exhibitions in China and overseas, communicate with customers,

and use our latest technology to solve the most practical needs of customers.

and use our latest technology to solve the most practical needs of customers.

Похожие товары

Стеллаж для транспортировки поддонов L-образной стеклянной полки

US $160.00-$180.00

Легко отлаживать станок для полировки стекла с ЧПУ

US $7200-$7400